khamosh

Disciple

Model: APC SURTD5000XLI-CC

So today, it started giving this error; Charger Battery Fault Exists and now it won't switch to direct AC mode.

When resetting it, it goes to AC mode for 5-10 seconds and when it detects the fault, it goes back to inverter mode and starts giving this error.

It is out of warranty. I received a quotation for an extended warranty a few months earlier when my 2 year warranty was about to expire, and it was ₹16,500, including GST, so I skipped it.

This was purchased from a relative for a considerably lesser amount and was using it for my gaming PC and a home NAS.

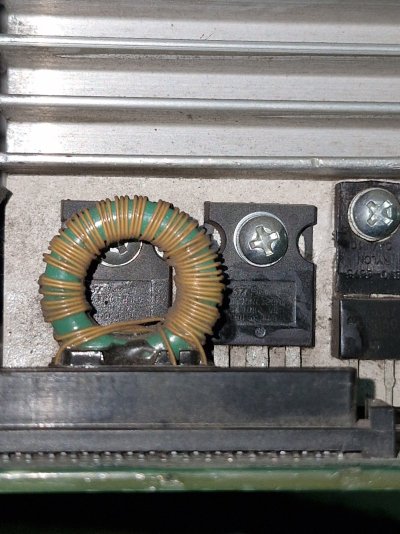

I opened it up. There was dust buildup (a lot of), so I cleaned it to observe any visible defects but couldn't see any.

I tried resetting it, but nothing happened.

I watched some YouTube videos [I watched the HINDI version] and figured out the charger section. I observed it twice, but still, no burst or leakage was found.

What should I do? Although, I live in a tier 2 city, I don't think these kinds of UPS are repaired here.

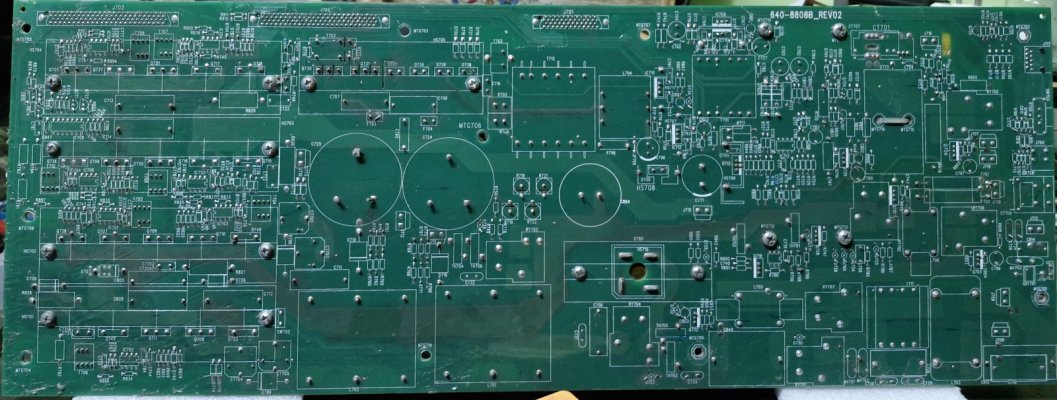

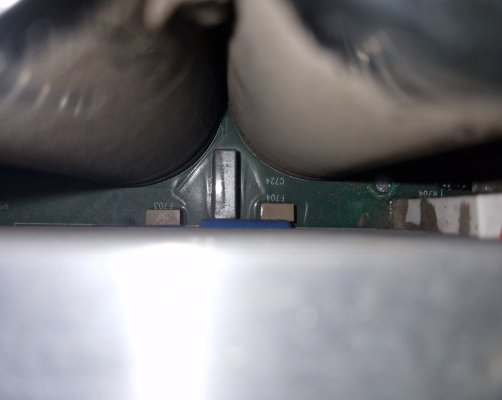

Sharing the PCB picture. If anyone can help, that would be incredible.

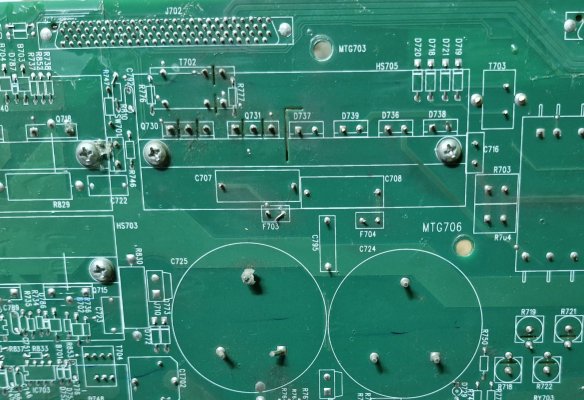

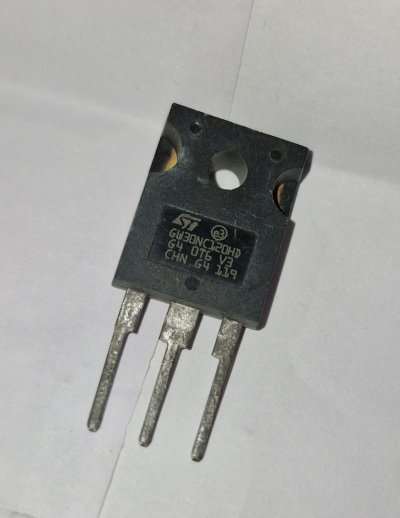

EDIT: Apparently, transistors Q730 has gone bad. How can I confirm this?

So today, it started giving this error; Charger Battery Fault Exists and now it won't switch to direct AC mode.

When resetting it, it goes to AC mode for 5-10 seconds and when it detects the fault, it goes back to inverter mode and starts giving this error.

It is out of warranty. I received a quotation for an extended warranty a few months earlier when my 2 year warranty was about to expire, and it was ₹16,500, including GST, so I skipped it.

This was purchased from a relative for a considerably lesser amount and was using it for my gaming PC and a home NAS.

I opened it up. There was dust buildup (a lot of), so I cleaned it to observe any visible defects but couldn't see any.

I tried resetting it, but nothing happened.

I watched some YouTube videos [I watched the HINDI version] and figured out the charger section. I observed it twice, but still, no burst or leakage was found.

What should I do? Although, I live in a tier 2 city, I don't think these kinds of UPS are repaired here.

Sharing the PCB picture. If anyone can help, that would be incredible.

EDIT: Apparently, transistors Q730 has gone bad. How can I confirm this?

Attachments

Last edited: