rsaeon

Herald

Actual capacity would probably be closer to 960Wh with these used 'C' grade cells but 1kWh sounds catchy. I'll be making a top-balancing BMS using Tasmota for this.

The entire premise of the project is ill-advised because we'd be dealing with large amounts of current since it's only a 3S pack and I'd like to build this to provide at least 500W for future expandability.

After a teardown that revealed 15 cells, and a purchase of 4 additional cells, I have 3 left over cells that'll be perfect to turn into a 3S pack that'll power simpler loads in my currently empty rack. Add in a charger and this becomes a DC UPS that'll keep my adblock running for weeks, ha.

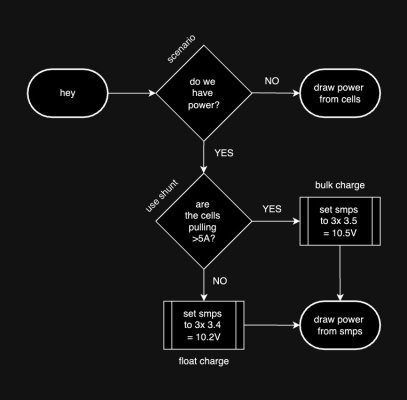

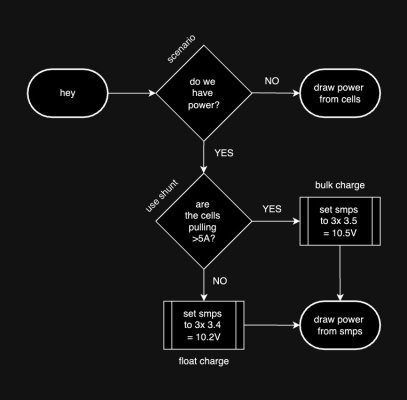

My first flow chart in over three decades:

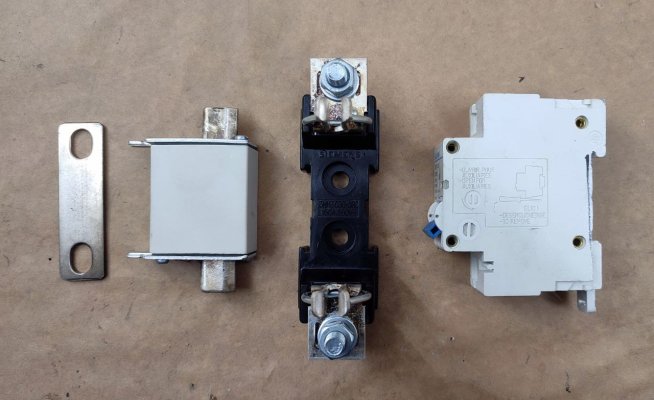

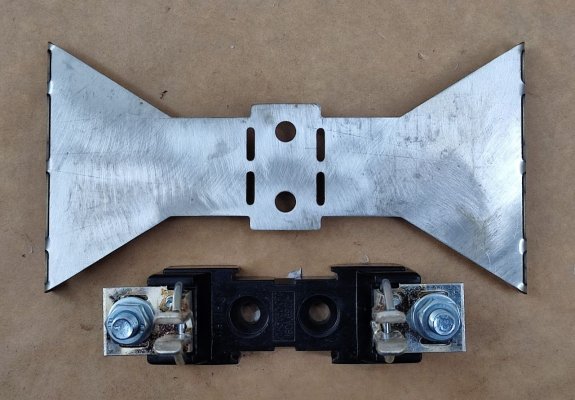

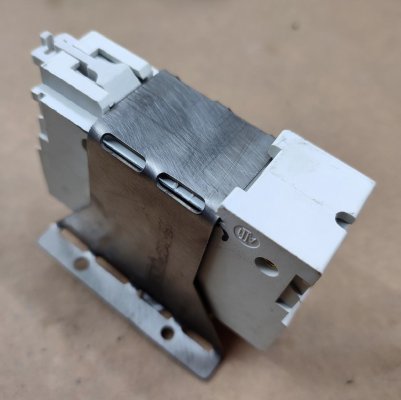

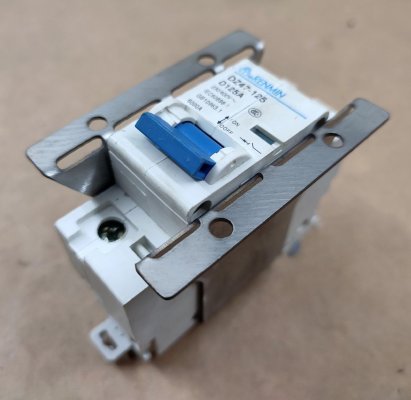

Some of the things I've gathered so far:

The cells will be encapsulated in 2mm G10 FR4 resin fiberglass sheets and 2mm stainless steel.

With a cell height of 36mm plus 2mm on each side for the fiberglass plus another 2mm for the stainless steel on both sides, the total height comes up to 44mm which is just shy of the 45-something-mm height of 1U.

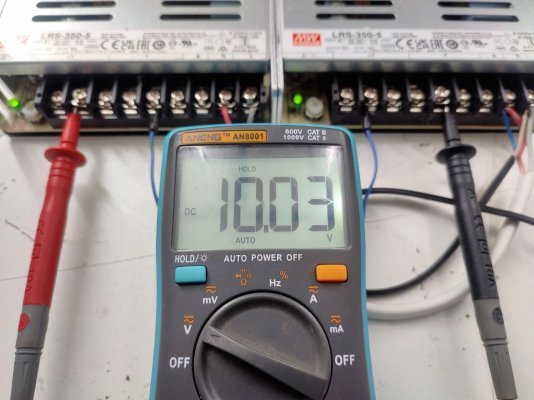

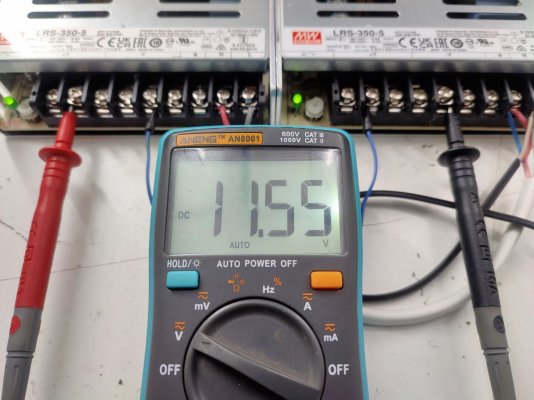

The two SMPS will be connected in series, they're 5V 60A each — so that's going to limit maximum power draw by itself to 600W. I wouldn't be loading more than 500W on this anyway so that leaves 100W left over for charging the cells after a power outage. Realistically, I don't expect to have anything over 200W connected to this.

But first, I'm going to make a Micro-Ohm Meter to make sure I have good connections since this is dealing with higher currents than I'm used to — that'll be a separate thread, I just finished building a prototype.

Budget is, as usual, very restricted (about 1k per week) so this'll take a while.

The entire premise of the project is ill-advised because we'd be dealing with large amounts of current since it's only a 3S pack and I'd like to build this to provide at least 500W for future expandability.

After a teardown that revealed 15 cells, and a purchase of 4 additional cells, I have 3 left over cells that'll be perfect to turn into a 3S pack that'll power simpler loads in my currently empty rack. Add in a charger and this becomes a DC UPS that'll keep my adblock running for weeks, ha.

My first flow chart in over three decades:

Some of the things I've gathered so far:

The cells will be encapsulated in 2mm G10 FR4 resin fiberglass sheets and 2mm stainless steel.

With a cell height of 36mm plus 2mm on each side for the fiberglass plus another 2mm for the stainless steel on both sides, the total height comes up to 44mm which is just shy of the 45-something-mm height of 1U.

The two SMPS will be connected in series, they're 5V 60A each — so that's going to limit maximum power draw by itself to 600W. I wouldn't be loading more than 500W on this anyway so that leaves 100W left over for charging the cells after a power outage. Realistically, I don't expect to have anything over 200W connected to this.

But first, I'm going to make a Micro-Ohm Meter to make sure I have good connections since this is dealing with higher currents than I'm used to — that'll be a separate thread, I just finished building a prototype.

Budget is, as usual, very restricted (about 1k per week) so this'll take a while.