Maybe off-topic, but i would like to chime in here, something i avoid doing.

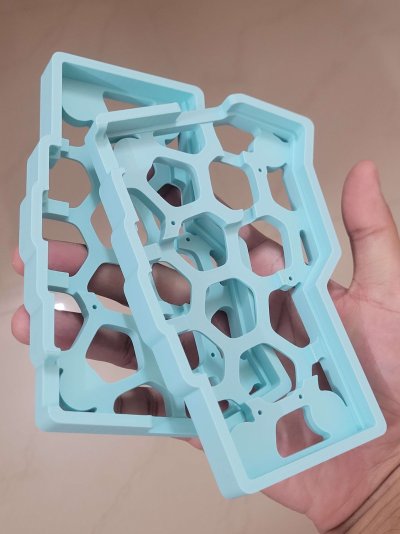

1) As someone who both designs my own prints and has printed designs from other creators, tolerances very significantly from machine to machine. Good designers, factor in tolerances (the general accepted practice is to factor in 0.2mm-0.3mm tolerance throughout the parts deigns, especially for snap fit parts.)

1b) even for the parts i print for others (see my sale thread), i expect the design to have tolerances. in cases where i think the print will not come out well, i inform the buyer before printing, so that they can take a call.

2) factoring tolerance is not the responsibility of the printer / printing service. that must come from the designer. Hence its called prototyping.

3) At the same time, the packaging used for most filament spools is not the best. hell, ive received broken spools of filament myself. It would have probably been better to package the parts in a right-size cardboard box, with bubble wrap and some crushed newspaper to bear some transport load.

4) 2 walls and 15% infill are generally not adequte (unless you print with 0.3mm wall widths). my general settings are 4 walls, tops and bottoms, 40% gyroid infill.

I am not trying to blame either party, since i think both sides could take something away from this situation.

Edit: added point 4)