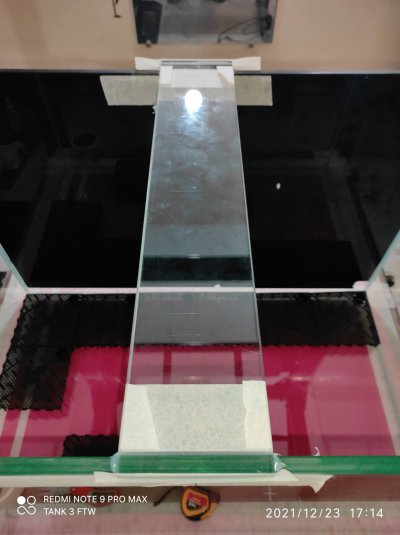

Yes, it is. African cichlids prefer high PH/GH/KH. My tap water is 8 PH so it all adds up 8.2 in the main tank. Excellent for them. PH is something one can't really fight against over time. Using chemicals makes it unstable : mores stress. Driftwood makes water brown. Almond leaves we need a lot of them to make any changes + they make the water brown that is hard to get rid of.Coral skeletons that make up crushed coral consist of calcium carbonate, which helps increase your aquarium's pH level up to 7.6 without the use of any chemicals.

Copied directly from google search result.

The founder of AFS talked about my substrate in the beginning of the video for a minute here lol

Last edited:

Another one, Cool.....how do u get time to maintain ur tanks!!

Another one, Cool.....how do u get time to maintain ur tanks!!