This one looks like a promising contender when I searched for something easier to modify with a larger enclosure for better thermals since that was a concern with the Polycab smart plug.

A few screws and it happily comes apart:

This one uses the Tuya CB3S module, which isn't compatible with Tasmota, so it'll need to be replaced.

The wiring and overall quality is very reassuring:

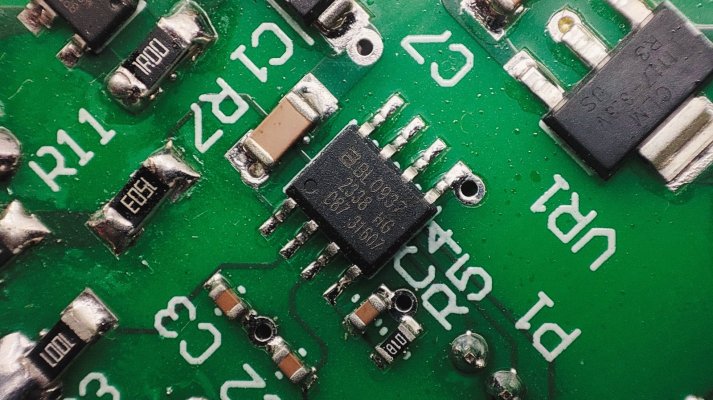

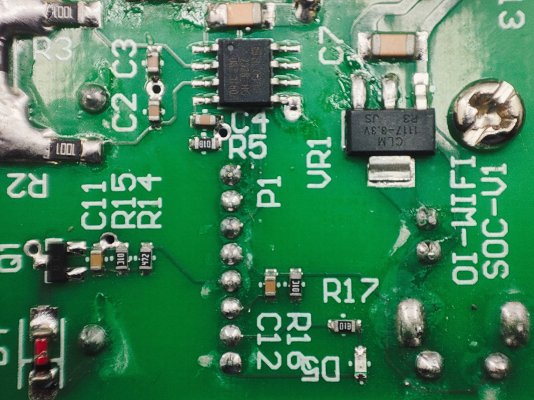

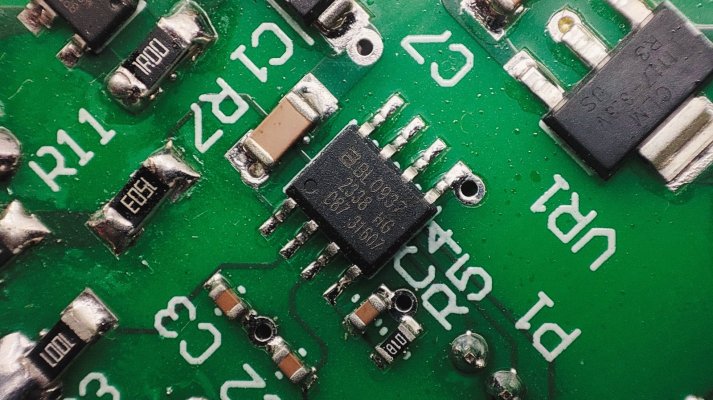

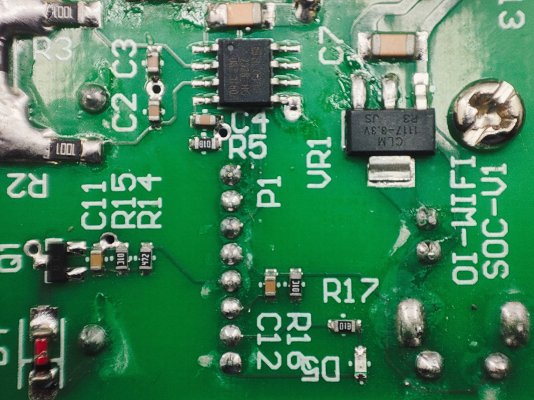

Powering monitoring is with the BL0937 energy meter chip, the same as the Polycab smart plugs.

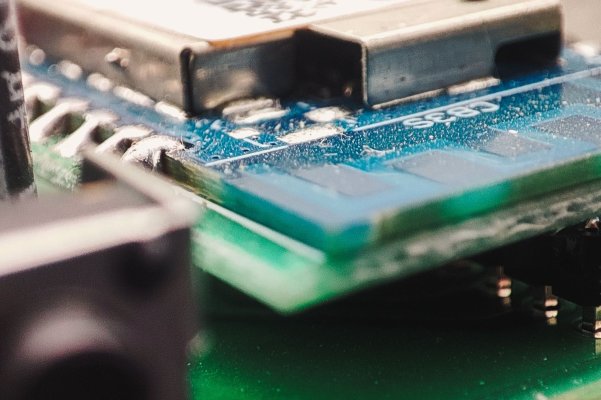

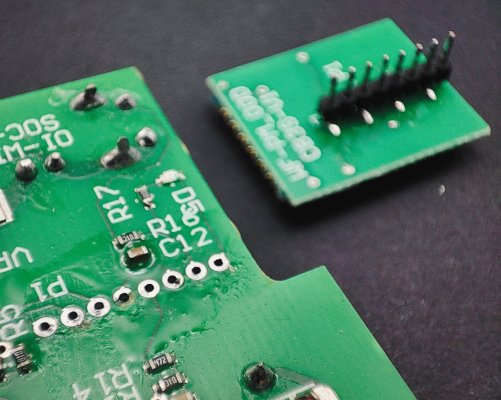

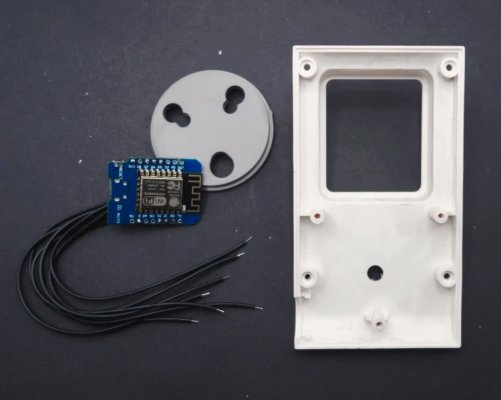

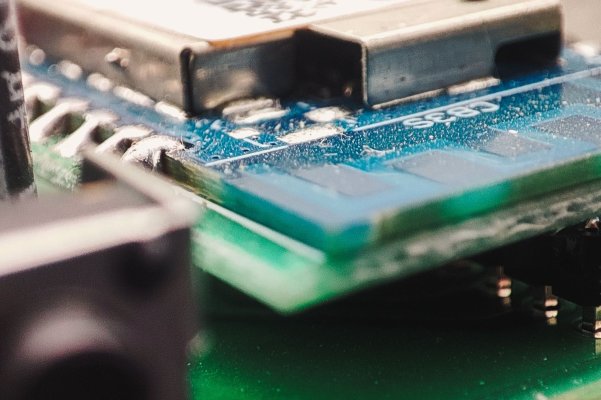

The Tuya module is on a carrier board that's on a header:

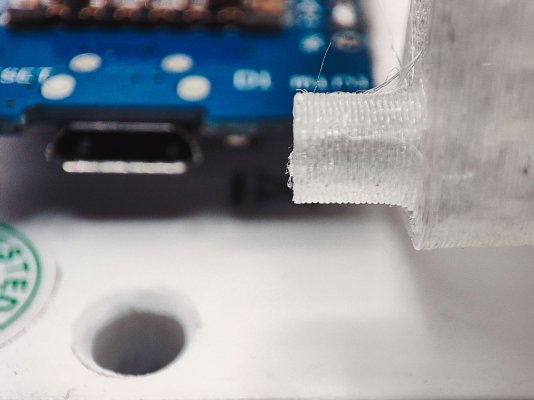

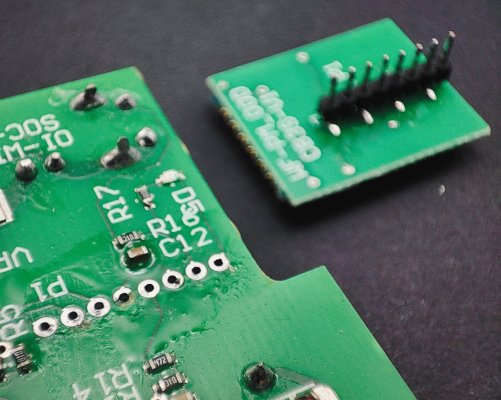

Careful with the pads as they might end up damaged during desoldering because they're so tiny:

A mica heatsink insulator helps with desoldering the castellations, just slide it underneath after heating up the pads two by two:

Still, unused pads might be lost:

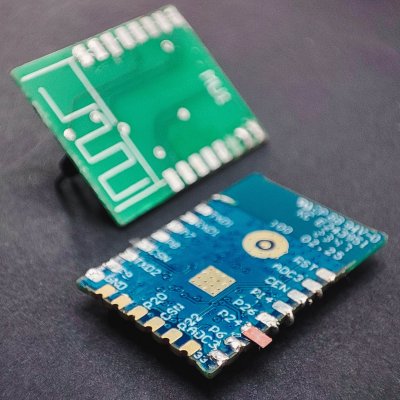

The same technique can be used to salvage ESP12F modules from damaged or failed projects:

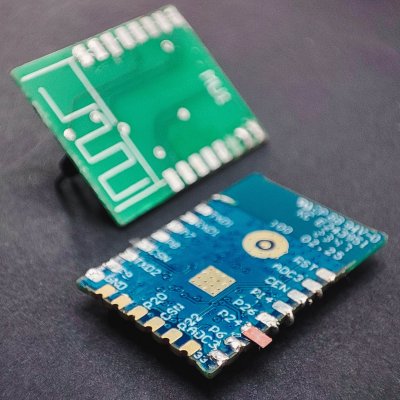

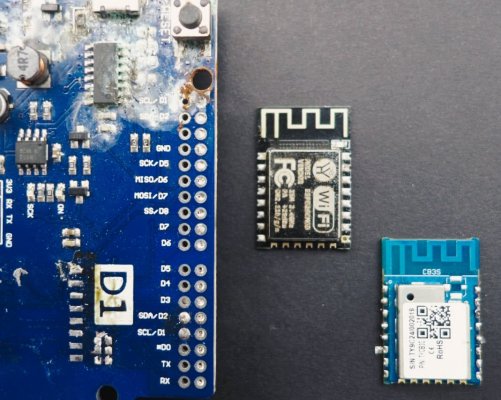

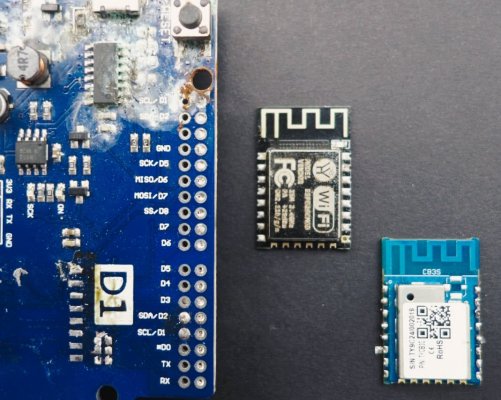

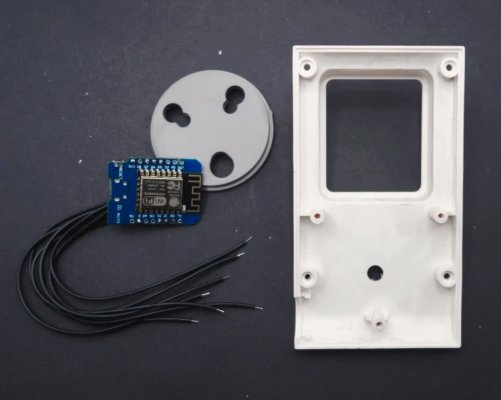

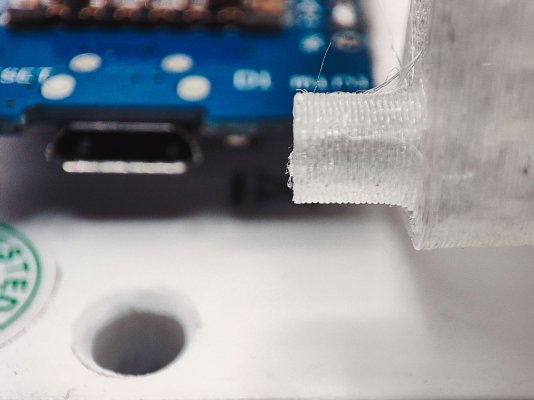

But the ESP12F isn't pin-compatible with the Tuya CB3S so we have to find something else, like this Wemos D1 Mini:

We could use the ESP12F without the carrier PCB, but that'll require additional components, a D1 mini is easier.

The tasmota template is based on the Polycab 16A one for simplicity:

From top to bottom, we have HLWBL SEL_i, HLWBL CF1, BL0937 CF, Switch, Relay, Ground, +3.3V and LED.

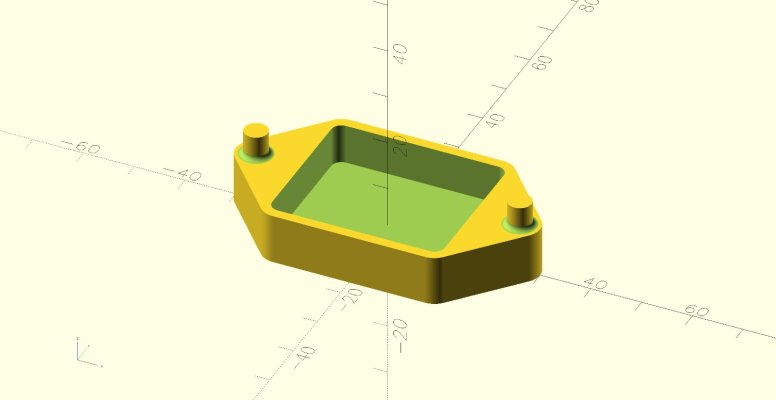

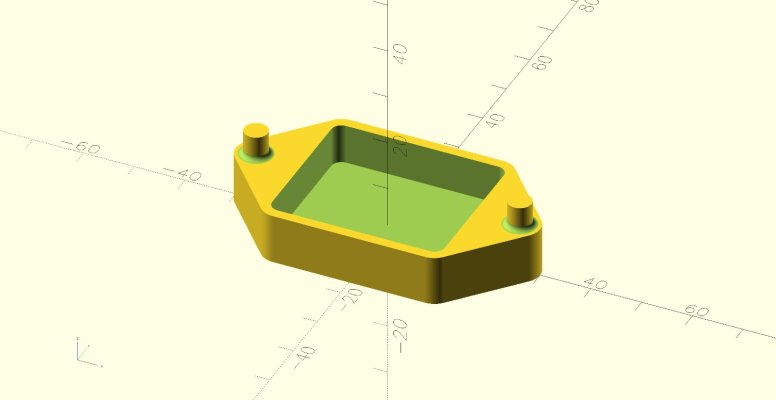

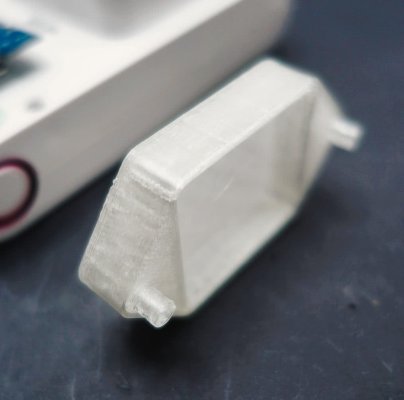

Made a simple cover in OpenSCAD:

Modelling in OpenSCAD is done through code, which can be very intuitive:

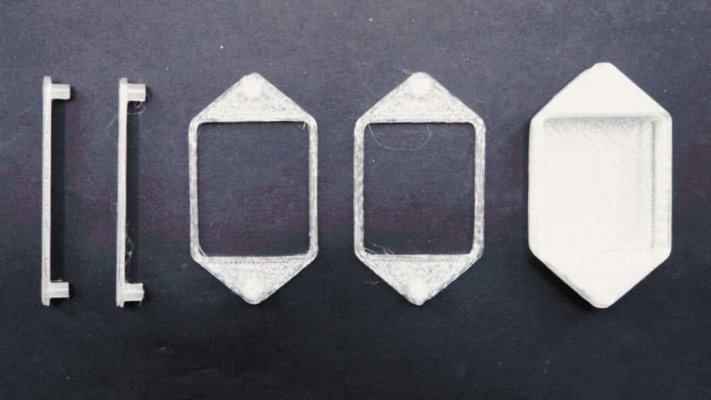

And then 3d-printed:

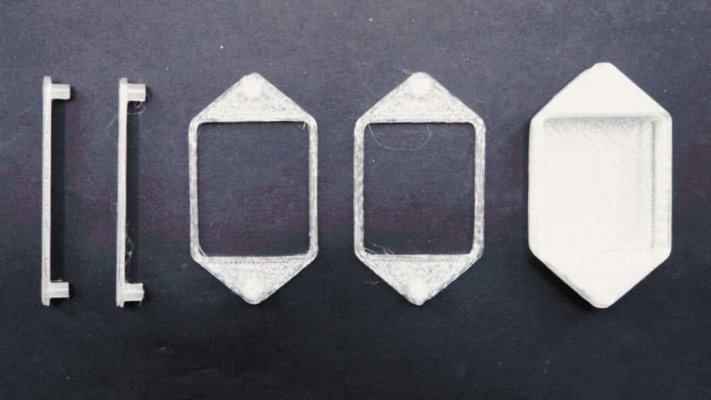

Iterations, the left-most one is my first 3d print ever:

It helps to have a well-tuned 3d printer, it took a couple of days:

The fillets on the pegs need the screw holes to be slightly countersunk for a good fit:

It took about 8 iterations to get a snug friction fit:

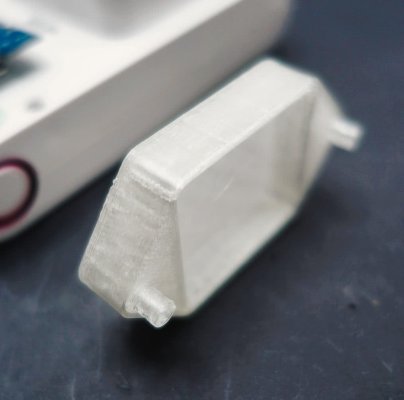

Looking good:

The translucent "natural" PLA filament was so worth it:

All done. Next, calibration: https://tasmota.github.io/docs/Power-Monitoring-Calibration/

A few screws and it happily comes apart:

This one uses the Tuya CB3S module, which isn't compatible with Tasmota, so it'll need to be replaced.

The wiring and overall quality is very reassuring:

Powering monitoring is with the BL0937 energy meter chip, the same as the Polycab smart plugs.

The Tuya module is on a carrier board that's on a header:

Careful with the pads as they might end up damaged during desoldering because they're so tiny:

A mica heatsink insulator helps with desoldering the castellations, just slide it underneath after heating up the pads two by two:

Still, unused pads might be lost:

The same technique can be used to salvage ESP12F modules from damaged or failed projects:

But the ESP12F isn't pin-compatible with the Tuya CB3S so we have to find something else, like this Wemos D1 Mini:

We could use the ESP12F without the carrier PCB, but that'll require additional components, a D1 mini is easier.

The tasmota template is based on the Polycab 16A one for simplicity:

Code:

{

"NAME":"209004",

"GPIO":[0,0,544,32,2720,2656,0,0,2624,320,224,0,0,0],

"FLAG":0,

"BASE":18

}From top to bottom, we have HLWBL SEL_i, HLWBL CF1, BL0937 CF, Switch, Relay, Ground, +3.3V and LED.

Made a simple cover in OpenSCAD:

Modelling in OpenSCAD is done through code, which can be very intuitive:

Code:

$fn=100;

points=[[30,25,0],[30,0,0],[0,25,0],[0,0,0]];

module end() {

cylinder(d=8, h=10);

}

module box(points, radius, height){

/* hackaday.com/2018/02/13/openscad-tieing-it-together-with-hull */

hull(){

for (p = points){

translate(p) cylinder(r=radius, h=height);

}

}

}

module peg() {

translate([0, 0, 10]) {

klam_fillet_cylinder(cylinder_height=5,

cylinder_radius=2.3,

fillet_radius_bottom=1,

fillet_radius_top=0,

nfaces=100);

}

}

module klam_fillet_cylinder(

cylinder_height=2,

cylinder_radius=1,

fillet_radius_bottom=1,

fillet_radius_top=0,

nfaces=100) {

/* klamfx.wordpress.com/2016/12/03/creating-a-filleted-cylinder-in-openscad */

union() {

cylinder(cylinder_height, r=cylinder_radius, $fn=nfaces);

if (fillet_radius_bottom > 0) {

difference() {

cylinder(fillet_radius_bottom,

r=cylinder_radius+fillet_radius_bottom,

$fn=nfaces);

translate([0, 0, fillet_radius_bottom])

rotate_extrude($fn=nfaces)

translate([cylinder_radius+fillet_radius_bottom, 0, 0])

circle(fillet_radius_bottom, $fn=nfaces);

}

}

if (fillet_radius_top > 0) {

difference() {

translate([0,0,cylinder_height-fillet_radius_top])

cylinder(fillet_radius_top,

r=cylinder_radius+fillet_radius_top,

$fn=nfaces);

translate([0, 0, cylinder_height-fillet_radius_top])

rotate_extrude($fn=nfaces)

translate([cylinder_radius+fillet_radius_top, 0, 0])

circle(fillet_radius_top, $fn=nfaces);

}

}

}

}

union() {

translate([-26, 0, 0]) {

end();

peg();

}

translate([26, 0, 0]) {

end();

peg();

}

difference() {

hull() {

translate([-15, -12.5, 0]) box(points, radius=4, height=10);

translate([-26, 0, 0]) end();

translate([26, 0, 0]) end();

}

translate([-15, -12.5, 2]) box(points, radius=2, height=8);

}

}And then 3d-printed:

Iterations, the left-most one is my first 3d print ever:

It helps to have a well-tuned 3d printer, it took a couple of days:

The fillets on the pegs need the screw holes to be slightly countersunk for a good fit:

It took about 8 iterations to get a snug friction fit:

Looking good:

The translucent "natural" PLA filament was so worth it:

All done. Next, calibration: https://tasmota.github.io/docs/Power-Monitoring-Calibration/

Last edited: