ze_cook

Level F

Fair warning: messing around with mains voltage (that the UPS generates) or high discharge rate batteries can set things on fire if you're not careful enough, or even kill you. Do not attempt this if you are new to these things, better let someone experienced handle.

Now that that's out of the way, let's start.

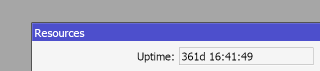

I have a modest homelab, with a main server (12th gen, 48tb raw storage), mini pc pfsense router, switch, access points etc. On average this setup consumes 70w, is fairly quiet and lives in the pooja room in our apartment. With frequent powercuts though (and no DG backup), the APC ups in charge of running the lab fails often. I have an APC BR-1000GIN that has a 24V 9Ah battery pack. It has a theoretical capacity of >200Wh, but with lead acid battery losses, inefficiencies in the UPS, aging, the same 70W load has an expected runtime is ~50 mins. This being a smart UPS, my server can communicate with it over an USB cable, and pulls stat from the UPS to report voltages, load, runtimes etc. live.

My server is setup to shutdown safely when battery level reaches 30% or runtime is at 20 minutes, whichever is earlier. This gives me enough of a safety margin, even if the batteries are degraded. Effectively, my UPS is able to run my server for 30 minutes, and powercuts often lasting >1hr means the a shut down is certain. Frequent shutdowns interfere with long running tasks, such as parity check (takes ~23Hrs for 16TB drives), which gets aborted in case of a shutdown. I wasn't happy with the UPS, and wanted a longer battery backup. APC sells external battery packs for the Smart UPS series, which adds 4x 12v 9Ah batteries, effectively tripling the capacity. Costs 10k ish, comes with a neat little enclosure that looks like the UPS, and has a removable connector. But paying 10k more for low capacity lead acid batteries felt like a rip off, and LiFePO4 has a far better energy density and cycle life, though they're more expensive.

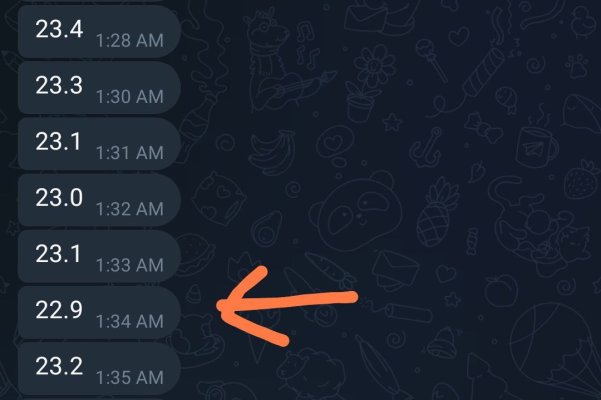

It was time to do some homework, can I even use LiFePO4 batteries? The graphs tell me that my UPS charges the battery up till 29.2 volts, which is exactly right for LFP full charge voltage, 3.65 * 8. It then idles the battery at 28V, which should be fine for LFP. The discharge curve for LFP is similar to lead acid, but flatter, hard to estimate state of charge (SOC) from voltages alone. For a typical SLA battery, at C/20 discharge rate, 10% SOC is ~23V, which corresponds to ~5% SOC for LFP batteries. LFP low voltage disconnect is normally set at 20V for a 8s pack, and the UPS should cut off before reaching 20V. Everything checked out electrically, was time to make some purchases.

I was wondering how I would connect the battery to the UPS, but then I came across this.

The exact external battery connector cable, being sold in retail market for 900rs (from an online shop called estorewale, here in Bangalore). Ordered, arrived in a few days. Has a sturdy connector, and 10AWG wires. The connector has 3 pins, labeled +, - and s, with s shorted with - on the other end, probably used as a sense pin. The connector being sorted, it was time to actually make the big purchase, the battery.

Went through some suppliers on indiamart, some unresponsive, some quoting outrageous prices, and one trying to sell me (possibly) C grade cells, with the assumption that at most I'll get 80% capacity from the get go. I had 2 choices here, either build the battery from bare cells, bus bars, bms etc, or simply buy a pre-built battery. I did not want to invest a lot in tools/time actually building the battery and possibly mess something up while doing so. Found one supplier who were promising, prices were decent, and finalized a deal. Cost me 37k all inclusive (battery, gst, shipping) for a 24v (8s) 100Ah LFP battery with metal enclosure, Daly 100A smart bms with BT. They took 2 weeks to make the battery and deliver to BLR, but the battery arrived in good condition. It arrived in a sturdy metal enclosure, 6AWG (copper?) cables and 120A anderson connectors, weighs probably around 20kg, has a nice spring loaded handle on top. The only downside I see are the rivets, as that makes the cells/bms inaccessible (unless i drill them, which is dangerous with charged LFP cells inside), but they do offer a 3 year warranty (not sure if you'll be able to claim it if anything goes wrong) so the rivets sort of makes sense.

The BMS does have a bluetooth module though, but it goes to sleep after an hour (can be changed) if the battery is idle. I had already ordered some 120A anderson connectors from sharvielectronics, but until they arrive, this is the sketchy setup I've done to activate the bluetooth module/charge the battery. Upon connecting to the BMS, the app asked for a passcode, which I had to pester the supplier for, but eventually they provided it, and I had full access.

The BMS does have a bluetooth module though, but it goes to sleep after an hour (can be changed) if the battery is idle. I had already ordered some 120A anderson connectors from sharvielectronics, but until they arrive, this is the sketchy setup I've done to activate the bluetooth module/charge the battery. Upon connecting to the BMS, the app asked for a passcode, which I had to pester the supplier for, but eventually they provided it, and I had full access.

The BMS has 4 cell temperature sensors and a MOSFET temp sensor. Surprisingly enough, all 8 cell voltages are very close, with difference of 1 milivolts (!!). Did not expect this at all. And this has not drifted as the battery charged from 49% to 64%. The supplier probably used matched cells, did a top balance and then discharged the battery (or the voltage sensors are faulty). It's charging fine with the UPS. Also, turns out the UPS does not require main batteries to be in to work, so I can remove the lead acid batteries entirely (does not require disassembly, just need to slide them out), and don't have to worry about 2 different battery chemistries in parallel.

Need to do a full discharge test to check the actual capacity, but waiting on the anderson connector to finalize the setup. A note on UPS, they are not meant to be running for longer durations, at full loads, and are specced accordingly. I will probably get by with my setup as my load is typically ~11% of the rated capacity, but if you do this yourself, take thermals and aging into consideration as well. Will try to keep this thread updated as I do more tests.

Now that that's out of the way, let's start.

I have a modest homelab, with a main server (12th gen, 48tb raw storage), mini pc pfsense router, switch, access points etc. On average this setup consumes 70w, is fairly quiet and lives in the pooja room in our apartment. With frequent powercuts though (and no DG backup), the APC ups in charge of running the lab fails often. I have an APC BR-1000GIN that has a 24V 9Ah battery pack. It has a theoretical capacity of >200Wh, but with lead acid battery losses, inefficiencies in the UPS, aging, the same 70W load has an expected runtime is ~50 mins. This being a smart UPS, my server can communicate with it over an USB cable, and pulls stat from the UPS to report voltages, load, runtimes etc. live.

My server is setup to shutdown safely when battery level reaches 30% or runtime is at 20 minutes, whichever is earlier. This gives me enough of a safety margin, even if the batteries are degraded. Effectively, my UPS is able to run my server for 30 minutes, and powercuts often lasting >1hr means the a shut down is certain. Frequent shutdowns interfere with long running tasks, such as parity check (takes ~23Hrs for 16TB drives), which gets aborted in case of a shutdown. I wasn't happy with the UPS, and wanted a longer battery backup. APC sells external battery packs for the Smart UPS series, which adds 4x 12v 9Ah batteries, effectively tripling the capacity. Costs 10k ish, comes with a neat little enclosure that looks like the UPS, and has a removable connector. But paying 10k more for low capacity lead acid batteries felt like a rip off, and LiFePO4 has a far better energy density and cycle life, though they're more expensive.

It was time to do some homework, can I even use LiFePO4 batteries? The graphs tell me that my UPS charges the battery up till 29.2 volts, which is exactly right for LFP full charge voltage, 3.65 * 8. It then idles the battery at 28V, which should be fine for LFP. The discharge curve for LFP is similar to lead acid, but flatter, hard to estimate state of charge (SOC) from voltages alone. For a typical SLA battery, at C/20 discharge rate, 10% SOC is ~23V, which corresponds to ~5% SOC for LFP batteries. LFP low voltage disconnect is normally set at 20V for a 8s pack, and the UPS should cut off before reaching 20V. Everything checked out electrically, was time to make some purchases.

I was wondering how I would connect the battery to the UPS, but then I came across this.

The exact external battery connector cable, being sold in retail market for 900rs (from an online shop called estorewale, here in Bangalore). Ordered, arrived in a few days. Has a sturdy connector, and 10AWG wires. The connector has 3 pins, labeled +, - and s, with s shorted with - on the other end, probably used as a sense pin. The connector being sorted, it was time to actually make the big purchase, the battery.

Went through some suppliers on indiamart, some unresponsive, some quoting outrageous prices, and one trying to sell me (possibly) C grade cells, with the assumption that at most I'll get 80% capacity from the get go. I had 2 choices here, either build the battery from bare cells, bus bars, bms etc, or simply buy a pre-built battery. I did not want to invest a lot in tools/time actually building the battery and possibly mess something up while doing so. Found one supplier who were promising, prices were decent, and finalized a deal. Cost me 37k all inclusive (battery, gst, shipping) for a 24v (8s) 100Ah LFP battery with metal enclosure, Daly 100A smart bms with BT. They took 2 weeks to make the battery and deliver to BLR, but the battery arrived in good condition. It arrived in a sturdy metal enclosure, 6AWG (copper?) cables and 120A anderson connectors, weighs probably around 20kg, has a nice spring loaded handle on top. The only downside I see are the rivets, as that makes the cells/bms inaccessible (unless i drill them, which is dangerous with charged LFP cells inside), but they do offer a 3 year warranty (not sure if you'll be able to claim it if anything goes wrong) so the rivets sort of makes sense.

The BMS has 4 cell temperature sensors and a MOSFET temp sensor. Surprisingly enough, all 8 cell voltages are very close, with difference of 1 milivolts (!!). Did not expect this at all. And this has not drifted as the battery charged from 49% to 64%. The supplier probably used matched cells, did a top balance and then discharged the battery (or the voltage sensors are faulty). It's charging fine with the UPS. Also, turns out the UPS does not require main batteries to be in to work, so I can remove the lead acid batteries entirely (does not require disassembly, just need to slide them out), and don't have to worry about 2 different battery chemistries in parallel.

Need to do a full discharge test to check the actual capacity, but waiting on the anderson connector to finalize the setup. A note on UPS, they are not meant to be running for longer durations, at full loads, and are specced accordingly. I will probably get by with my setup as my load is typically ~11% of the rated capacity, but if you do this yourself, take thermals and aging into consideration as well. Will try to keep this thread updated as I do more tests.