I can try to help you with any modifications through CAD if you can share the file.Can anyone suggest a free and easy to use tool to modify STL files? I have a simple requirement (see attached) and think I may be able to it myself by modifying an STL on Thingsverse. Any help is appreciated. Cheers.

3D Printing Thread

- Thread starter ibose

- Start date

-

- Tags

- 3d printer

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Slayer88

Herald

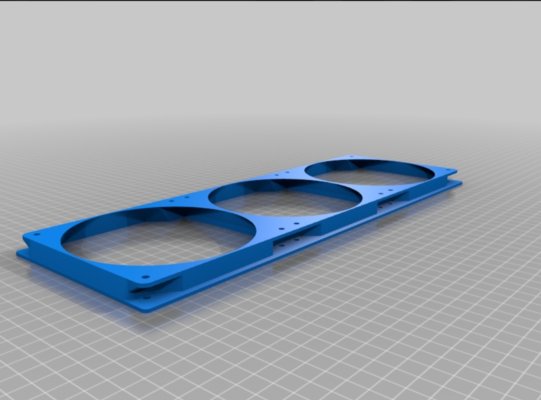

Thanks so much, man! Basically, id like to keep the holes in the same places just the center part cutout.I can try to help you with any modifications through CAD if you can share the file.

Just to clarify, i would like the output like the white frame.

STL is at the link below (couldn't attach as it's too large)

My Customized Fan shroud for 360mm water cooling radiator (parametric) by Bl4ck_B4ron

Customized version of https://www.thingiverse.com/thing:4325366Created with Customizer! https://www.thingiverse.com/apps/customizer/run?thing_id=4325366

I would like the height of the frame to be 10mm please.

Thank you again!

Attachments

Done! The file is uploaded to Thingiverse: https://www.thingiverse.com/thing:6666099. Let me know if any changes need to be made...Thanks so much, man! Basically, id like to keep the holes in the same places just the center part cutout.

Just to clarify, i would like the output like the white frame.

STL is at the link below (couldn't attach as it's too large)

My Customized Fan shroud for 360mm water cooling radiator (parametric) by Bl4ck_B4ron

Customized version of https://www.thingiverse.com/thing:4325366Created with Customizer! https://www.thingiverse.com/apps/customizer/run?thing_id=4325366www.thingiverse.com

I would like the height of the frame to be 10mm please.

Thank you again!

Slayer88

Herald

You sir are a legend. Not sure where you are based, but if you are in Mumbai I will buy you a beer (or whatever is your poison) Thanks a ton!!Done! The file is uploaded to Thingiverse: https://www.thingiverse.com/thing:6666099. Let me know if any changes need to be made...

Hey, thanks for the offer, but I'm happy to help a fellow member outYou sir are a legend. Not sure where you are based, but if you are in Mumbai I will buy you a beer (or whatever is your poison) Thanks a ton!!

What software are you using to modify the STL file? I tried blender which does work good with mesh files but is not suitable for CAD related.I can try to help you with any modifications through CAD if you can share the file.

What software are you using to modify the STL file? I tried blender which does work good with mesh files but is not suitable for CAD related.

I recreated the model from scratch

in fusion 360 from the 120mm fan specifications. The geometry was pretty simple...

Let me know if you need help with modelling anything...

Last edited:

Hey that great to know. I personally use Fusion, but have shifted to onshape. For slicing I use Prusaslicer. Sketch up is amazing to begin with and you can in fact use it for 3d prints. Seems like you're re you an architect. Also what printer did you get...Hey, new to 3d printing here. Glad to see there already is a community around this.

I've placed the order, but not gotten my printer yet.

Wanted to ask what 3d software people use to model and what do you all suggest I learn?

I know 2d autocad and sketchup.

Thanks.

Haha my software suite gave it away. I did study to be an architect, but I do custom work with glass and resin now.Hey that great to know. I personally use Fusion, but have shifted to onshape. For slicing I use Prusaslicer. Sketch up is amazing to begin with and you can in fact use it for 3d prints. Seems like you're re you an architect. Also what printer did you get...

What about you?

Great that I can use Sketchup to start. After that you recommend Fusion 360? I heard a lot about Orca slicer.

I got the Neptune 4 max because it was the biggest I could afford. Plan on using it for work to make moulds for casting.

Going a little crazy with the number of 3d printer reviews and "5 things to know before 3d printing" videos on youtube.

Haha my software suite gave it away. I did study to be an architect, but I do custom work with glass and resin now.

What about you?

Great that I can use Sketchup to start. After that you recommend Fusion 360? I heard a lot about Orca slicer.

I got the Neptune 4 max because it was the biggest I could afford. Plan on using it for work to make moulds for casting.

Going a little crazy with the number of 3d printer reviews and "5 things to know before 3d printing" videos on youtube.

I have the "humble" Ender 3. Good you went for the large print module. A warning that if you plan to modify even one part, you'll end up spending more than the cost of the printer in upgrades. Fusion is great, so is Onshape. Why not try both and see. Same for OrcaSlicer.

Nice to see you do casting. You create a sand cast from the 3d printed parts, right? I'm from a MechE background and usually design and print functional parts like brackets, enclosures, etc, so the Ender 3 is perfect. Attached some pics of the printer if you're interested...

Attachments

Man these tech things always look enticed ng to me and keep on making me buy them on whim. Only thing keeping me at bay is that i don't have time to make myself indulge in these due to very lack of time because of work.

Sometimes i think of starting a YouTube channel for these techs as i love to do these and like to make myself indulge in these but then a YouTube channel is not a sureshot way to earn a living but i also am not able to try on sides too.

Sometimes i think of starting a YouTube channel for these techs as i love to do these and like to make myself indulge in these but then a YouTube channel is not a sureshot way to earn a living but i also am not able to try on sides too.

Dude, that's so cool. Very interested.

Yea I'll try both those software and see what works more intuitively for me.

I'd like to try sandcasting but not there yet. Figured I'd start with silicone moulds for casting resin. It's a new avenue I'm going into as far as work is concerned. I don't know squat about any of it. My usual work is more along the lines of flat glass panels with designs and such. 3d for me is layering glass but that gets very heavy very fast.

Hey tell me, in our climate, does pla have issues with say things like drawer organisors or wall peg board cups to hold screws or small tools?

The kind of work I do, incase you are interested in seeing: Google photos album

Basically the opposite of you, decorative but not much functionality

Yea I'll try both those software and see what works more intuitively for me.

I'd like to try sandcasting but not there yet. Figured I'd start with silicone moulds for casting resin. It's a new avenue I'm going into as far as work is concerned. I don't know squat about any of it. My usual work is more along the lines of flat glass panels with designs and such. 3d for me is layering glass but that gets very heavy very fast.

Hey tell me, in our climate, does pla have issues with say things like drawer organisors or wall peg board cups to hold screws or small tools?

The kind of work I do, incase you are interested in seeing: Google photos album

Basically the opposite of you, decorative but not much functionality

Yeah, but the larger publishers always get ahead due to their company-size production and teams. The blogging space is even worse after Sep 2023 due to Google. I have some much to write on my own site but the time is just not there.Man these tech things always look enticed ng to me and keep on making me buy them on whim. Only thing keeping me at bay is that i don't have time to make myself indulge in these due to very lack of time because of work.

Sometimes i think of starting a YouTube channel for these techs as i love to do these and like to make myself indulge in these but then a YouTube channel is not a sureshot way to earn a living but i also am not able to try on sides too.

Dude, that's so cool. Very interested.

Yea I'll try both those software and see what works more intuitively for me.

I'd like to try sandcasting but not there yet. Figured I'd start with silicone moulds for casting resin. It's a new avenue I'm going into as far as work is concerned. I don't know squat about any of it. My usual work is more along the lines of flat glass panels with designs and such. 3d for me is layering glass but that gets very heavy very fast.

Hey tell me, in our climate, does pla have issues with say things like drawer organisors or wall peg board cups to hold screws or small tools?

The kind of work I do, incase you are interested in seeing: Google photos album

Basically the opposite of you, decorative but not much functionality

That's genuinely amazing. The scale is mindblowing. Do you use some kind of solder to join the glass pieces?

PLA is not that bad unless it is left unused for months. PETG suffers a lot from striging so I got a filament dryer for it. Look into gridfinity if you want a desk organizer. The ikea pegboard is pretty good for wall.

That's bang on actually. Yea, in one type of glass we use solder to hold the joints together. Then it gets chemically hardened and oxidized to make it all black.Do you use some kind of solder to join the glass pieces?

Thanks man. I'll look into it.

Moon1530

Beginner

BlenderCan anyone suggest a free and easy to use tool to modify STL files? I have a simple requirement (see attached) and think I may be able to it myself by modifying an STL on Thingsverse. Any help is appreciated. Cheers.

cyberwarfare

Galvanizer

Im not sure if you all are aware, but there is a whole community on Discord for indian 3DP. Let me link it here: https://discord.gg/fFpfXe3E

RougeDiner

Beginner

Can you link it again it's not there anymoreIm not sure if you all are aware, but there is a whole community on Discord for indian 3DP. Let me link it here: https://discord.gg/fFpfXe3E

Join the Voron India Discord Server!

Check out the Voron India community on Discord - hang out with 1285 other members and enjoy free voice and text chat.

rsaeon

Innovator

Alright, so begins my journey! Last year, I got a FLSun Q5, it's a delta 3D printer. It was an open box customer return that was discounted down to Rs 10k. Looks like whoever bought it, didn't realize they had to assemble it, so they returned it. I was finally able to start using it a couple of months ago.

I don't know much about 3D printing or 3D printers, but I've been seeing them come up in my random browsing every now and then and learned that there are two types of people: those who like to 3D print things, and those who like to play around with 3D printers. Turns out, I'm more of the second than the first, haha.

But yeah, Deltas always intrigued me — I remember wanting one because it looked cool about 10 years ago when I had no idea about anything 3D printer related.

Here it is, I've some basic mods that I'll explain:

When I first started using it, I got a few failures where the part would just fly away, so I found this 18 inch by 18 inch shelving rack on Amazon and I'm using it as an partial enclosure. It was wobbly as are most racks of this kind but once I sealed up three sides with 2mm acrylic, it became impressively solid.

Link to the rack: https://www.amazon.in/dp/B0DKC685HB/

I'm drying dessicant in that photo. I've learned that I need a lot of it, everywhere, especially with the monsoon. So I leave it on a steel plate for about six hours with the bed set to 90° C. I'll come up with a better solution later, this works well for now.

I got the orange-green color changing kind, it's less toxic than the prettier blue-pink one. To recharge/refresh it, you basically need to warm it up to encourage it to release the water it trapped, here you can see it's been successfully rejuvenated on the plate sitting on a 90° printer bed, but there are saturated beads in the same environment:

Wild.

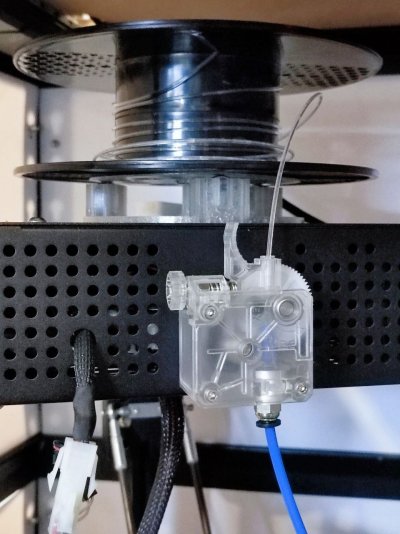

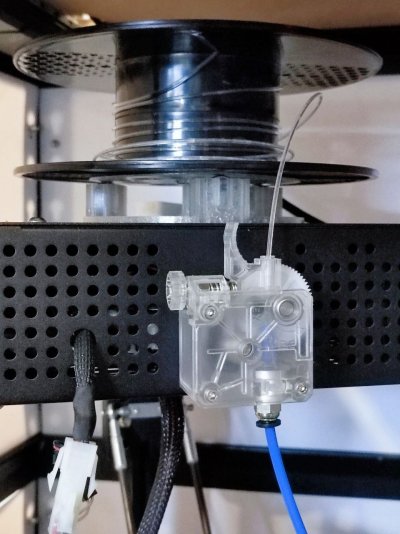

Before I learned about needing to dry filament, I had a filament jam in the extruder, which I disassembled and had a lot of parts flying everywhere. I had to get a replacement, so I got a transparent one from Novo3D for a few hundred:

This is a clone of the Titan extruder, and is the exact kind that came with the 3D printer, so I didn't need to change any settings to start using it.

There are basically two types of extruders, they're those geared things that push filament. This one is the Bowden type, named after the braking system, where a wire travels through a tube. It's usually considered less precise but allows for a lighter head, which translates to faster printing speeds. The other type is direct drive, that's where the extruder feeds filament directly into the hot end without a PTFE tube.

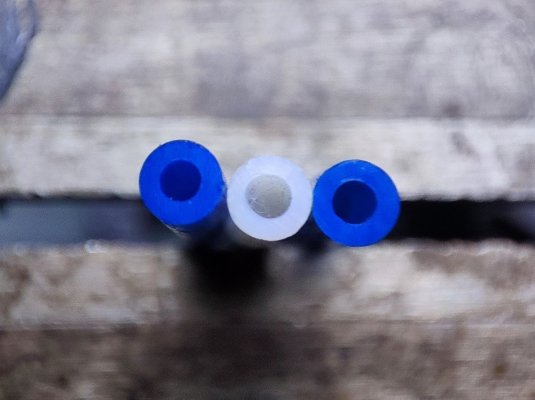

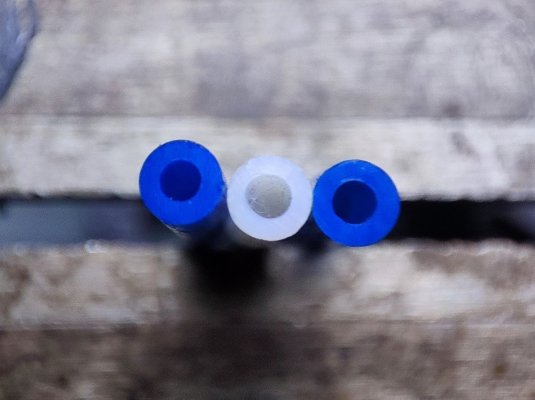

There's usually some slack in the PTFE tube with a Bowden-type extruder, and this results in imprecise extrusion. Youtubers recommend replacing the stock bowden tube with something called a capricorn one. I haven't been able to find that particular brand of tube. I found a lot of sellers selling regular PTFE tubes in blue and calling it capricorn, but they're not actual capricorn tubes

The difference is that the regular tube has an inner diameter of 2mm, which translates to a slack of 3mm either way over the length of a meter or half a meter with standard 1.75mm filament. I found a seller on Amazon selling a PTFE tube with an inner diameter of 1.9mm, which is what a capricorn tube should be.

Link to the tube: https://www.amazon.in/dp/B08MDFW5PS

Here's a close-up of the stock tube in the middle, an incorrectly labelled capricorn on the right, and the 1.9mm ID tube on the left:

The difference is almost imperceptible, but it's supposed to make for better prints.

Here they are with filament inside:

There's a larger gap between the inner wall and filament on the right two compared to the left one.

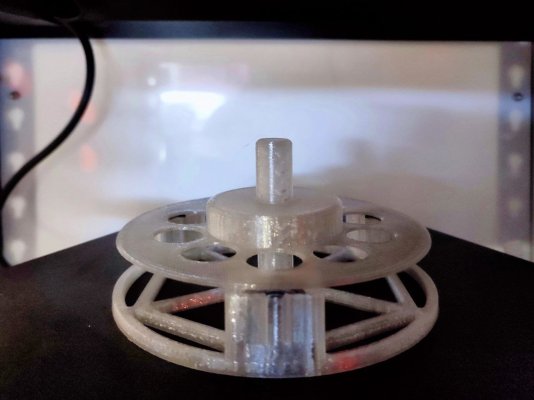

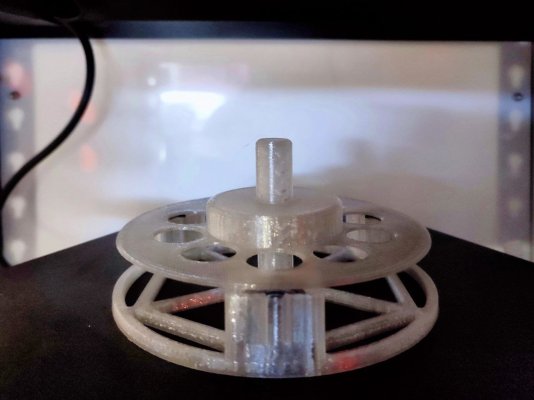

Lastly, the vertical spool holder got stuck a few times, so I looked for a solution and found that someone had designed a horizontal spool holder, and it became my first functional print:

Link to the model: https://www.printables.com/model/414162-flsun-q5-horizontal-spool-holder

I'll update again after I figure out a few more mods.

I don't know much about 3D printing or 3D printers, but I've been seeing them come up in my random browsing every now and then and learned that there are two types of people: those who like to 3D print things, and those who like to play around with 3D printers. Turns out, I'm more of the second than the first, haha.

But yeah, Deltas always intrigued me — I remember wanting one because it looked cool about 10 years ago when I had no idea about anything 3D printer related.

Here it is, I've some basic mods that I'll explain:

When I first started using it, I got a few failures where the part would just fly away, so I found this 18 inch by 18 inch shelving rack on Amazon and I'm using it as an partial enclosure. It was wobbly as are most racks of this kind but once I sealed up three sides with 2mm acrylic, it became impressively solid.

Link to the rack: https://www.amazon.in/dp/B0DKC685HB/

I'm drying dessicant in that photo. I've learned that I need a lot of it, everywhere, especially with the monsoon. So I leave it on a steel plate for about six hours with the bed set to 90° C. I'll come up with a better solution later, this works well for now.

I got the orange-green color changing kind, it's less toxic than the prettier blue-pink one. To recharge/refresh it, you basically need to warm it up to encourage it to release the water it trapped, here you can see it's been successfully rejuvenated on the plate sitting on a 90° printer bed, but there are saturated beads in the same environment:

Wild.

Before I learned about needing to dry filament, I had a filament jam in the extruder, which I disassembled and had a lot of parts flying everywhere. I had to get a replacement, so I got a transparent one from Novo3D for a few hundred:

This is a clone of the Titan extruder, and is the exact kind that came with the 3D printer, so I didn't need to change any settings to start using it.

There are basically two types of extruders, they're those geared things that push filament. This one is the Bowden type, named after the braking system, where a wire travels through a tube. It's usually considered less precise but allows for a lighter head, which translates to faster printing speeds. The other type is direct drive, that's where the extruder feeds filament directly into the hot end without a PTFE tube.

There's usually some slack in the PTFE tube with a Bowden-type extruder, and this results in imprecise extrusion. Youtubers recommend replacing the stock bowden tube with something called a capricorn one. I haven't been able to find that particular brand of tube. I found a lot of sellers selling regular PTFE tubes in blue and calling it capricorn, but they're not actual capricorn tubes

The difference is that the regular tube has an inner diameter of 2mm, which translates to a slack of 3mm either way over the length of a meter or half a meter with standard 1.75mm filament. I found a seller on Amazon selling a PTFE tube with an inner diameter of 1.9mm, which is what a capricorn tube should be.

Link to the tube: https://www.amazon.in/dp/B08MDFW5PS

Here's a close-up of the stock tube in the middle, an incorrectly labelled capricorn on the right, and the 1.9mm ID tube on the left:

The difference is almost imperceptible, but it's supposed to make for better prints.

Here they are with filament inside:

There's a larger gap between the inner wall and filament on the right two compared to the left one.

Lastly, the vertical spool holder got stuck a few times, so I looked for a solution and found that someone had designed a horizontal spool holder, and it became my first functional print:

Link to the model: https://www.printables.com/model/414162-flsun-q5-horizontal-spool-holder

I'll update again after I figure out a few more mods.