Part1

The contenders:

- Fedus: https://www.amazon.in/dp/B09XBD522D

- Anchor: https://www.amazon.in/dp/B00H7BI1BK

- Nippo: https://www.amazon.in/dp/B0BW5VDLV9

- Wipro: https://www.amazon.in/dp/B0B7X2625M

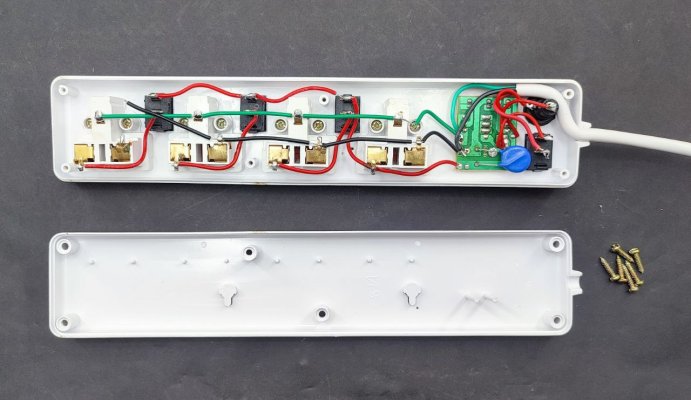

Fedus Extension Board

Out of these four, this is the highest-priced, but this isn't reflected in its quality. It's in the labour needed to manufacture it, as you'll see. Plastic quality is not good by any quantifier, whether weight, texture, or finish. But it does have a fuse holder, and this one came with three extra fuses. Switches are illuminated.Rear:

Internals:

Bad design:

Solder quality (acceptable):

Plug and wire:

Findings:

- Cable is rated as having 23 strands of 0.0052, which is probably less than 0.5 sq mm.

- Overall construction is not very good, nor clean. Human hair and shavings were found inside.

- Internal wiring is not confidence-inspiring.

- Screws are rusty.

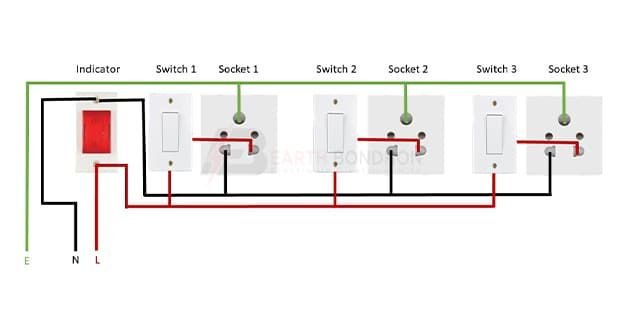

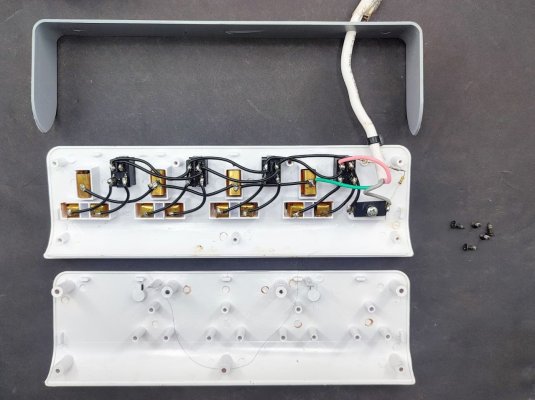

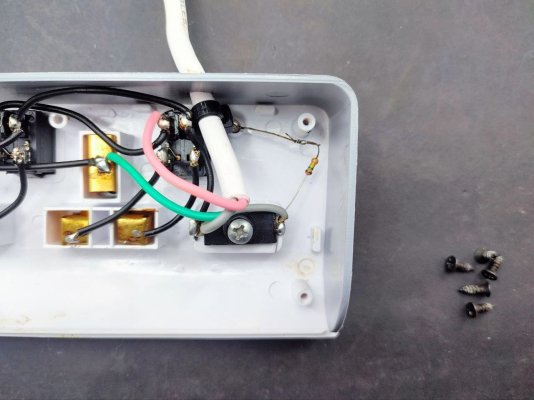

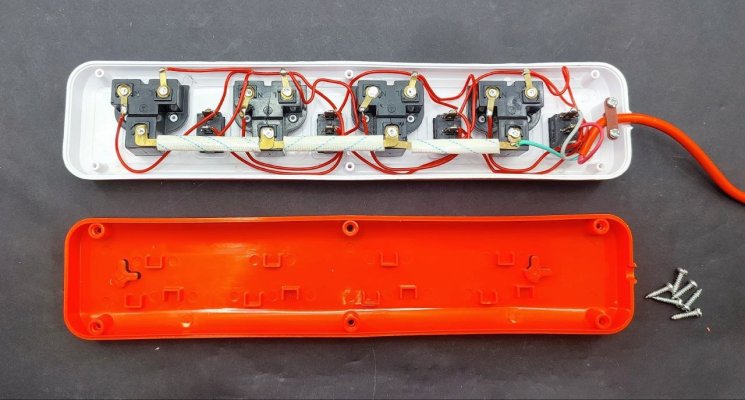

Anchor by Panasonic Extension Board

The most feature-rich of these four is at an excellent price. Fuse holder is a somewhat premium top-mount screw-type. Plastics are excellent and have a nostalgic texture and finish. Switches are non-illuminated.Rear:

Internals:

Solder quality (excellent):

Plug and wire:

Findings:

- Cable is properly labelled and rated at 0.5 sqmm x 3 at 1100V

- Overall construction is above average, and assembly is clean, design is mature.

- Wiring detached from one socket, rendering it inoperable.

- Only three sockets have switches.

- Screws are yellow zinc plated.

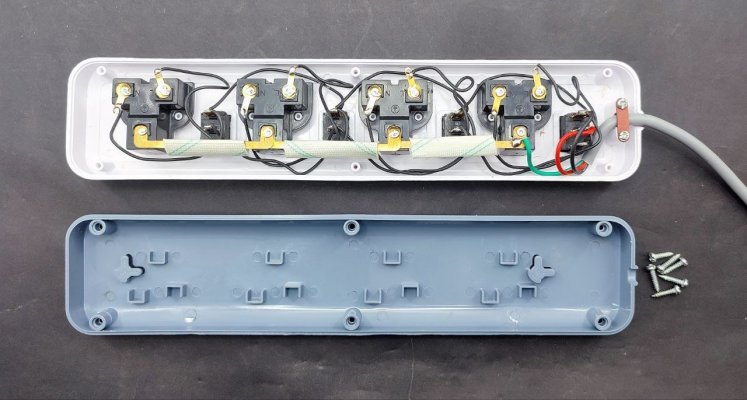

NIPPO 4KV Surge Protector

Mis-labelled as a surge protector, this is a regular power strip without a fuse or protection. Quality is acceptable but unremarkable. Socket spacing is generous because of switch placement. This uses newer illuminated switches that simplify internal wiring. Basically a clone of the Wipro.Rear:

Internals:

Solder quality (acceptable):

Plug and wire:

Findings:

- Cable is rated at 0.5 sq mm but has the thinnest insulation of all four.

- Overall construction is acceptable with obvious signs of cost optimisation (non-uniform silhouette).

- Wiring is acceptable, internal wires are silicon-insulated but not confidence-inspiring.

- Screws are bright zinc plated.

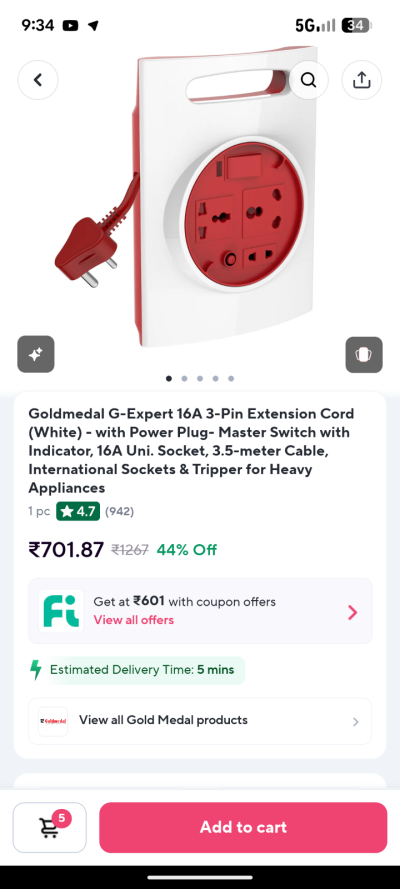

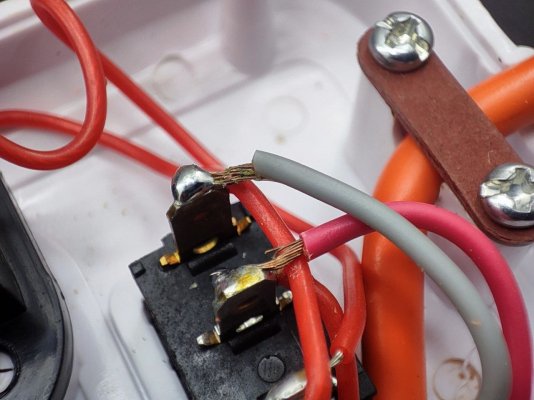

Wipro Multi Socket Spike Guard

Also mis-labelled, this is a basic power strip without a fuse or protection, a clone of the Nippo. Quality is acceptable but unremarkable. Socket spacing is generous because of switch placement. This uses newer illuminated switches that simplify internal wiring.Rear:

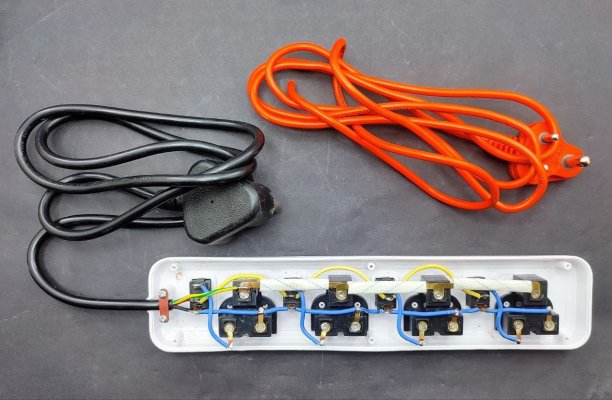

Internals:

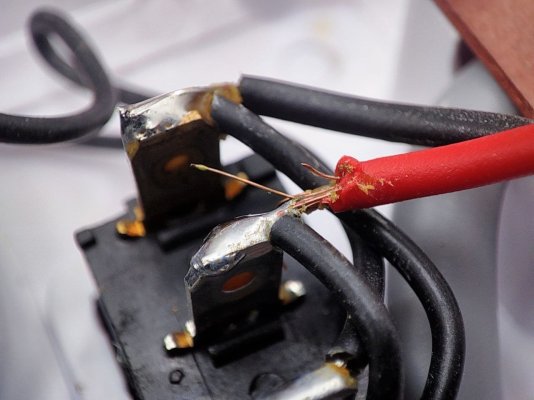

Solder quality (acceptable):

Plug and wire:

Findings:

- Cable is unrated and shows signs of bruising at the plug.

- Overall construction is acceptable with obvious signs of cost optimisation (non-uniform silhouette).

- Wiring is acceptable, internal wires are silicon-insulated but not confidence-inspiring.

- Screws are bright zinc plated.

Summary of Part 1:

None of these are particularly recommended; they're all a mild fire hazard in one way or the other (human hair and wire congestion in the Fedus, floating neutral wire in the Anchor and stray wire strands in both the Nippo and the Wipro). However, it could be argued that any electrical fault that may develop would be countered by an MCB or by the fault burning up before it could cause any significant damage. I'll leave the verdict up for you to decide on what's acceptable, hence the multitude of photos to draw your own conclusions.

The Anchor is very endearing, it has a retro charm, and I would be happy to have it somewhere non-critical. Probably in a place where I'd gaze upon it as I sip chai and reminisce about a life that revolved around dot matrix printers, before the internet.

The others are almost forgettable. The Wipro and Nippo can be serviceable if you're willing to have an electrician inspect it and maybe even consider redoing the internal wiring. I like their socket spacing so I'll be fixing them up for computer lab type use, like here I replaced the cable with a giant 16A plug that came with a power supply:

More parts will be added to this thread as time and budget allows in the coming weeks/months.

Last edited: