It started with this thread on TE. My 12 year old Inspiron 1545 battery (not original) was not charging. Initial thought was that battery was dead, but after some tests found that it was the adapter cable which was faulty. Replaced the adapter cable, meanwhile I also ordered 6 18650 type cells from here , thanks to @SunnyBoi for the website link.

Although it is best advised that batteries should be spot welded so that less heat dissipates inside the battery while welding, hence less chance of cell damage. But on the other hand, if you do normal soldering and manage to reduce the contact time of soldering iron and battery terminal (less than 2 secs), the heat transfer can be minimized. I decided to go with soldering method for obvious reasons.

Posting this guide here, hoping it might help someone who prefers and enjoys DIY.

Gathered all the required tools, Soldering iron, soldering flux, soldering metal, plier, batteries and a 100 grit sand paper.

Battery was opened already during my previous experiment. Most batteries require to be opened by force, same was the case here..

Next thing was to sand the battery terminals with sand paper, had 100 grit with me so used that.

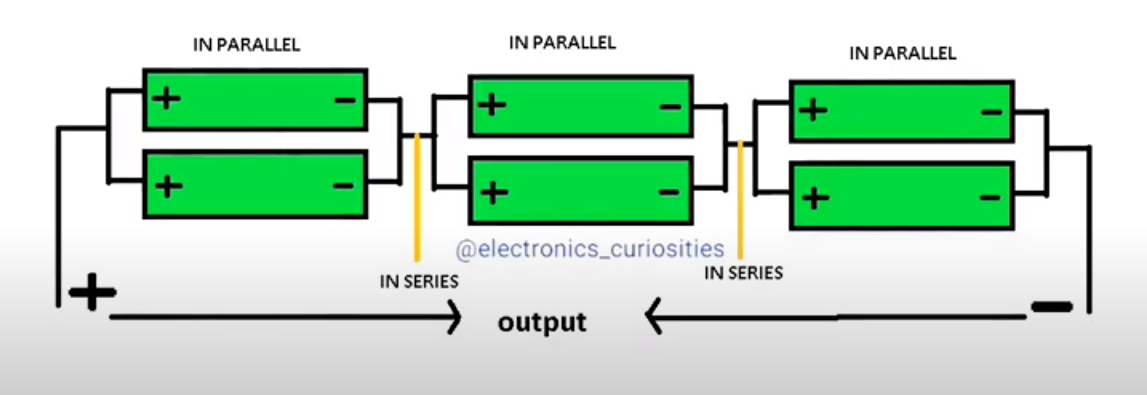

In this dell battery the cells are connected in series in a pair of 2 cells as shown below (image taken from internet):

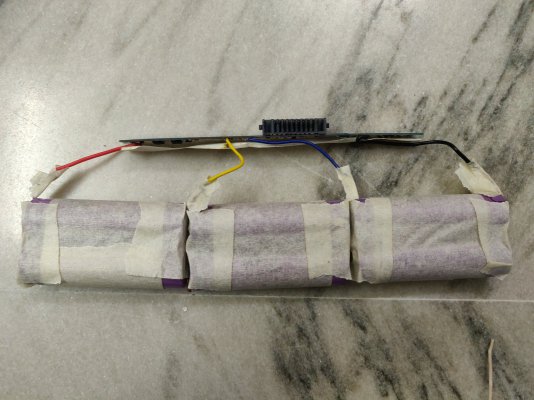

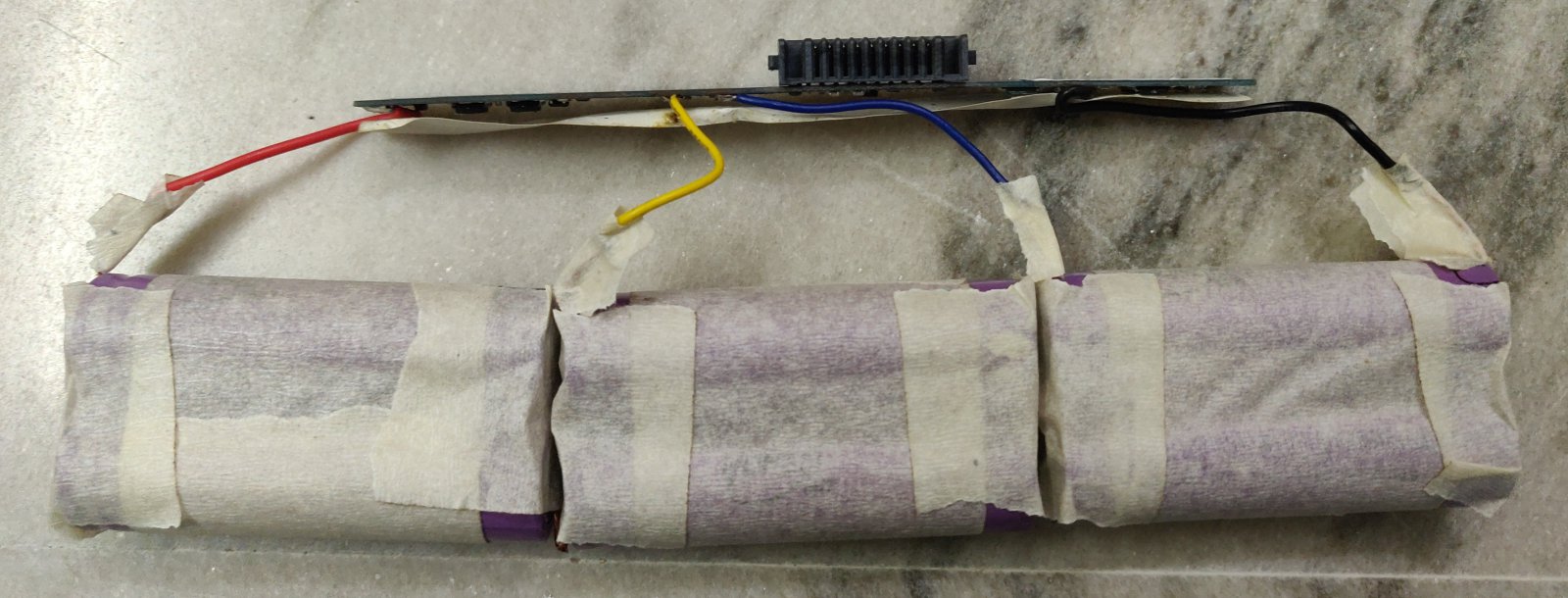

3 cell pairs are taped together, also got the naked copper wires from a 2 mm wire, 2 small ones for end terminals and 2 large once to connect the pairs together in series:

End terminals are soldered, next task is to solder them in series as shown in diagram:

This step was very risky, I was a little careless and accidentally shorted the terminals while soldering, It melted the copper wire in an instant, thankfully, my fingers were not burnt.

Lesson learned was to be extra cautious while soldering the terminals.

Cell pairs are now soldered in series:

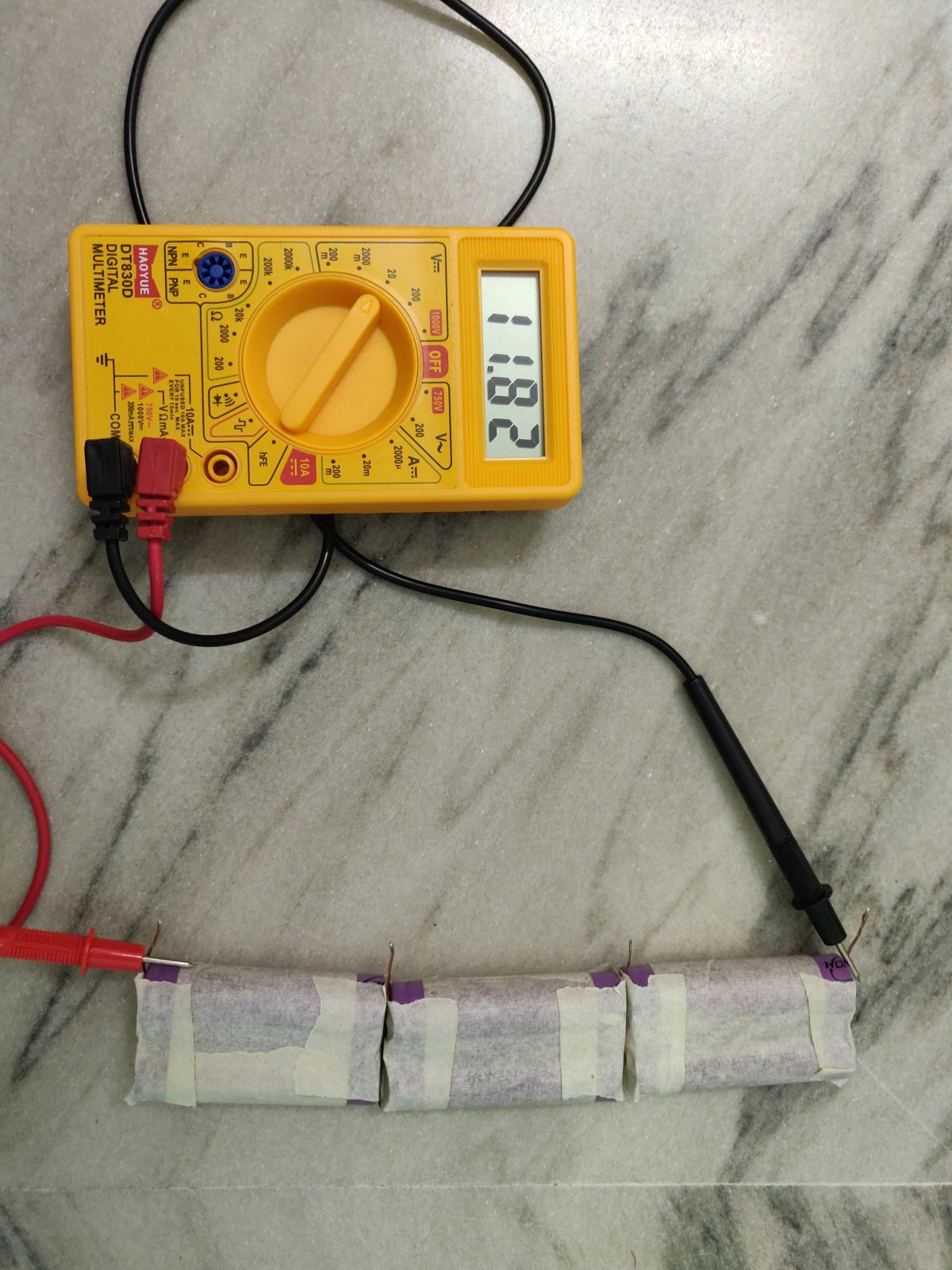

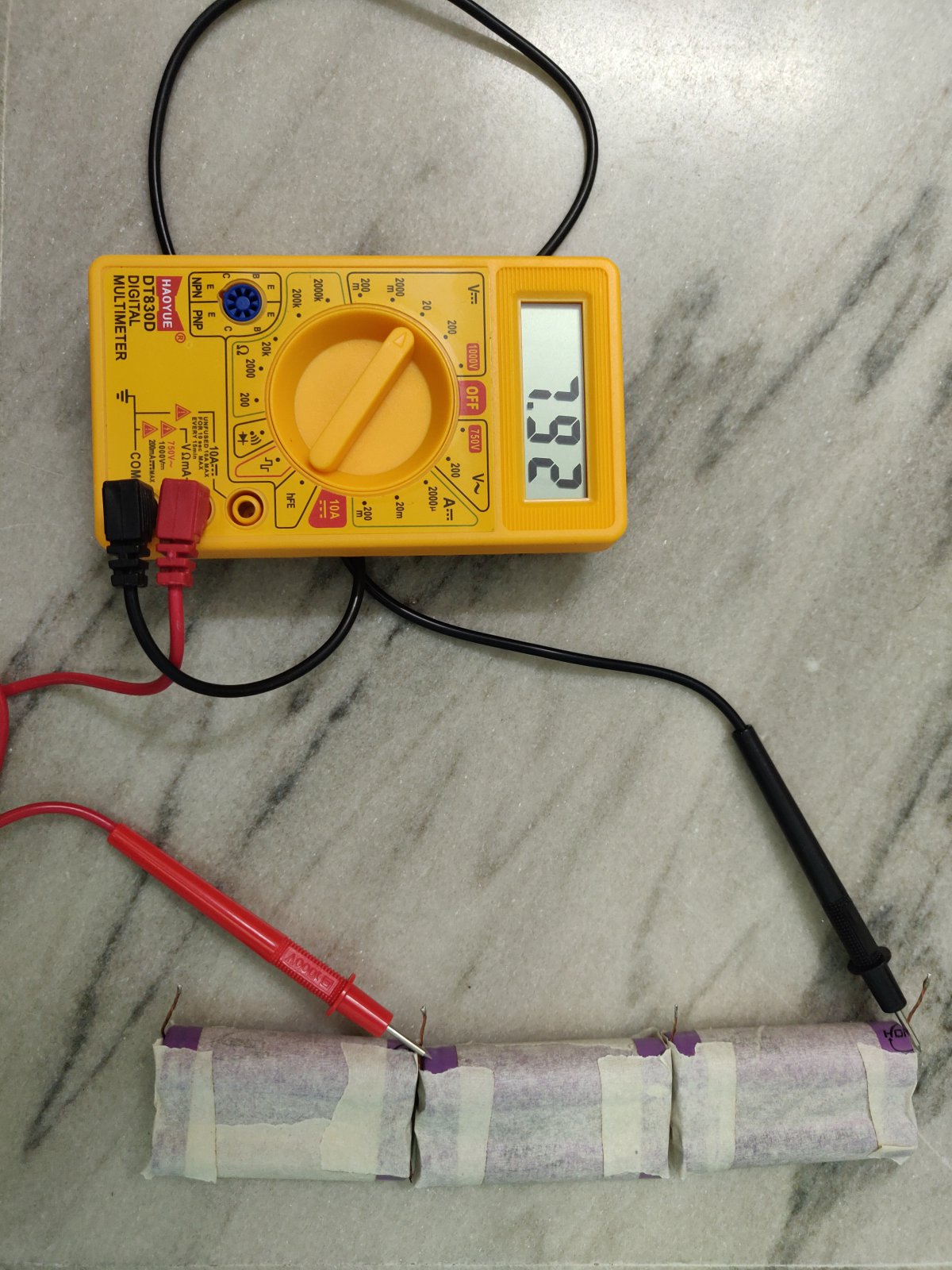

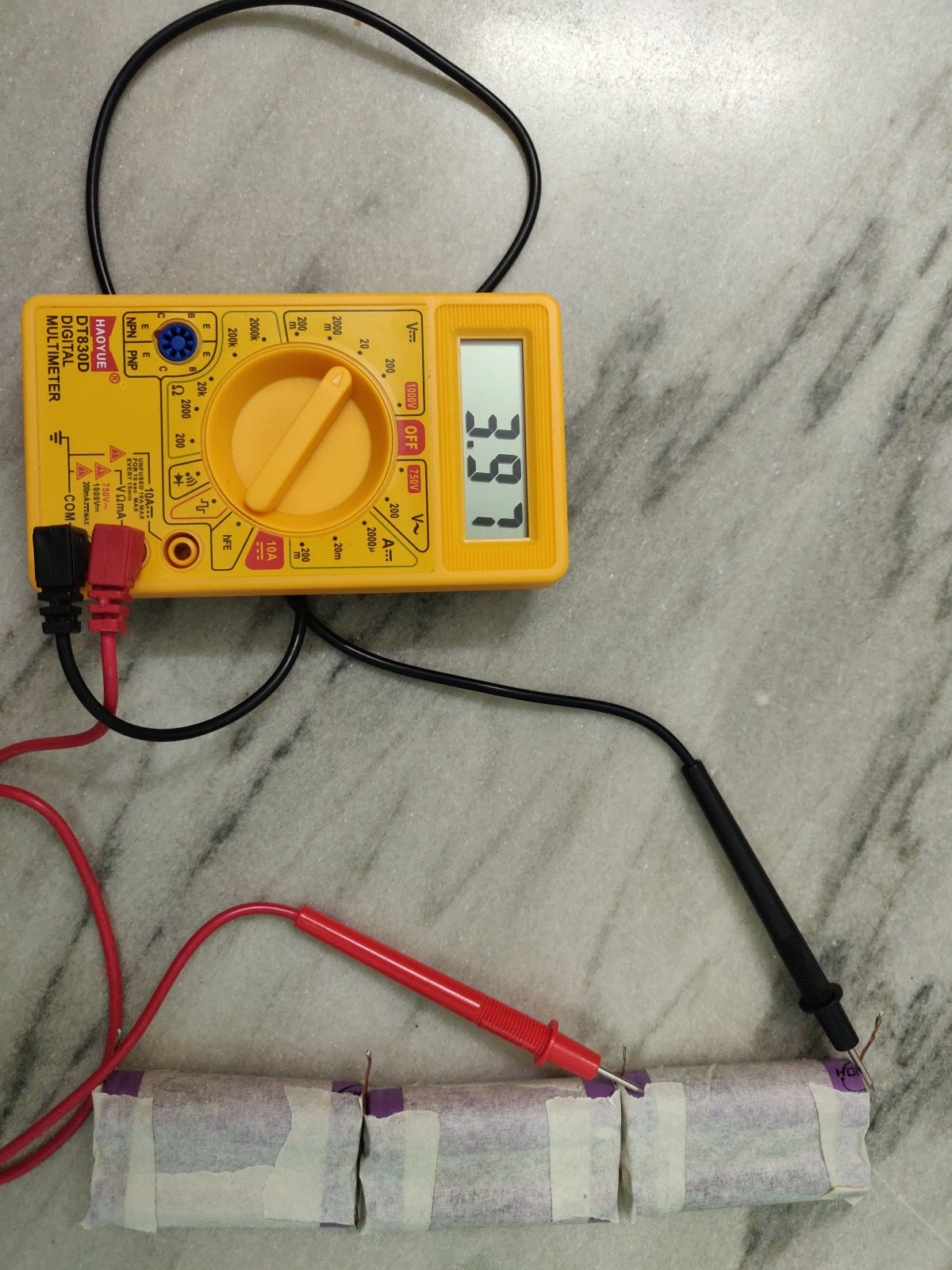

Testing the voltage and making sure that connections are ok:

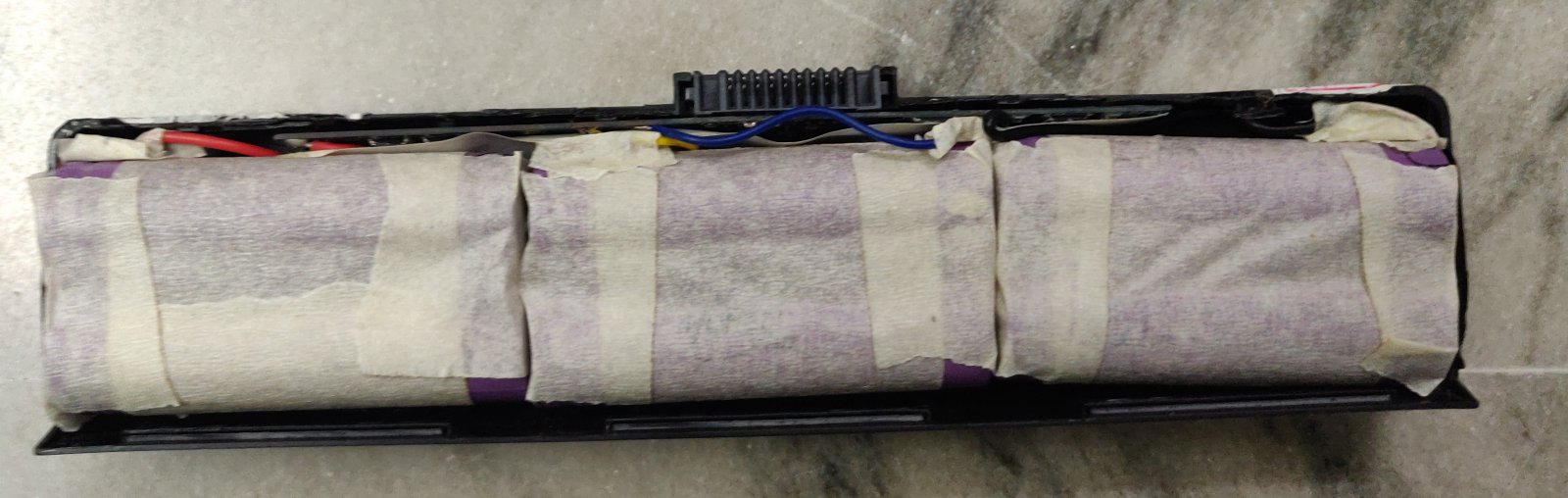

Soldered the battery circuit:

Put the pack back inside battery case:

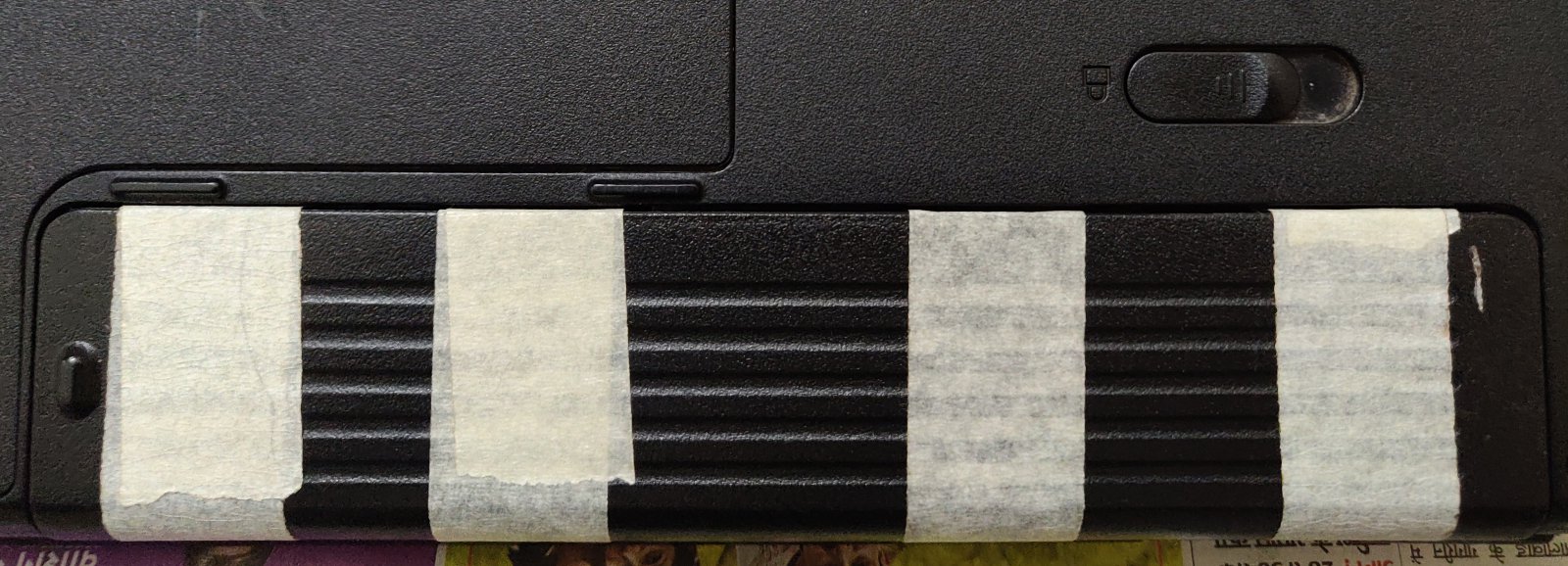

Packed the battery by putting the back cover and taping it at 4 places, battery back in it's place in the laptop:

And finally, booted the laptop, battery percentage shows as 0 percent. Left the laptop to charge for an hour and it was at 100 percent.

The backup is decent (more than 1 hour). Windows will calibrate it better with more charge and discharge cycles.

Happy DIY

Although it is best advised that batteries should be spot welded so that less heat dissipates inside the battery while welding, hence less chance of cell damage. But on the other hand, if you do normal soldering and manage to reduce the contact time of soldering iron and battery terminal (less than 2 secs), the heat transfer can be minimized. I decided to go with soldering method for obvious reasons.

Posting this guide here, hoping it might help someone who prefers and enjoys DIY.

Gathered all the required tools, Soldering iron, soldering flux, soldering metal, plier, batteries and a 100 grit sand paper.

Battery was opened already during my previous experiment. Most batteries require to be opened by force, same was the case here..

Next thing was to sand the battery terminals with sand paper, had 100 grit with me so used that.

In this dell battery the cells are connected in series in a pair of 2 cells as shown below (image taken from internet):

3 cell pairs are taped together, also got the naked copper wires from a 2 mm wire, 2 small ones for end terminals and 2 large once to connect the pairs together in series:

End terminals are soldered, next task is to solder them in series as shown in diagram:

This step was very risky, I was a little careless and accidentally shorted the terminals while soldering, It melted the copper wire in an instant, thankfully, my fingers were not burnt.

Lesson learned was to be extra cautious while soldering the terminals.

Cell pairs are now soldered in series:

Testing the voltage and making sure that connections are ok:

Soldered the battery circuit:

Put the pack back inside battery case:

Packed the battery by putting the back cover and taping it at 4 places, battery back in it's place in the laptop:

And finally, booted the laptop, battery percentage shows as 0 percent. Left the laptop to charge for an hour and it was at 100 percent.

The backup is decent (more than 1 hour). Windows will calibrate it better with more charge and discharge cycles.

Happy DIY

Attachments

Last edited: