Raghunandan said:I didnt ask him to "see what happens". I said it "WILL" work if its a transformer inside. I really doubt if you know anything about a transformer or electrical devices.

Do you even understand electricity? How do you say that its dangerous? You dont cite any reason. Amazing ignorance!!

Raghu.

And you assumed he would know what a transformer is.

Raghu - the fact is that any advice on mains is considered dangerous.

There are repair forums on the net (I myself am a member of a few of them) where the discussion of mains is banned. You know why? Because you need an engineering degree to be able to fiddle with the mains, and if you ask questions on an open forum you potentially involve the forum and its members in litigation.

As for your question to whether I understand electricity at all, I'll not comment on what I see pretty clearly as an aggressive post trying to call me out. Instead, let me try and see if I can explain how a transformer works and how his could be a very dangerous piece of advice, since you've asked why. Since I specify my own transformers for manufacturing, his will get a little technical, but I'll try and keep it as simple as I can.

A transformer is a device that changes one alternating volage to another. It does this by the means of two windings, one is the primary and the other is a secondary. This is wound around what is known as the 'core'. It cannot, as Raghu confirms, transfer DC voltages. The reason Lord Nemesis gets the shock is that for the first millisecond that the battery is connected, there is a voltage ramp within the transformer that transfers energy to the second winding, so you get a pretty high voltage. If you were to leave the battery connected, the voltage would cease to exist.

Transformers have the following ratings:

VA: The Volt-Amp rating, or the amount of power that the core can take before it saturates. At saturation, the transformer starts shedding its voltage output for incremental current draw.

Voltage rating: This is not primary or seconary voltage, but the voltage at which insulation breakdown happens. This is why transformers are rated as Class II (single insulation) or Class III (double insulation).

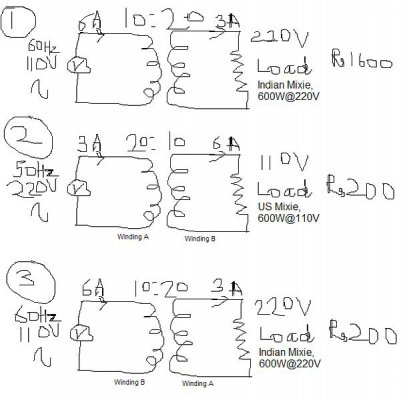

Primary and secondary voltage: This is basically the input and output voltage, determined by the turns ratio. Soon, however, we'll demonstrate that using only this rating to determine whether a transformer can be connected either way, is defective, and possibly dangerous.

Operating frequency: Not trivial. A transformer in an SMPS operates at several hundred kHz, whereas a transformer that operates on domestic supply operates at 50 (US:60) Hz. This has implications on the core type and size.

Operating temperature: There is a maximum specified oprating temperature for the insulation. Usually the core is robust enough to survive to a couple of hundred degrees, and so is the winding wire. But insulation usually does not survive past 200 degrees.

Current draw: The wire inside the transformer is rated to operate at a specific current draw. Whereas enamelled copper wire used in transformers is pretty robust, we will later see how this is the primary

problem in this situation.

problem in this situation.There are many variations on this theme (r-core, toroidals, autoformers, etc), but now to the topic at hand. Anyone wanting more information on the technical aspects of transformers or electricty can PM me.

We will assume that the transformer (assuming there was a transformer and not an SMPS in the converter, and Trajan knew what a transformer was when he opened it up) is a regular class II single-insulated 2:1 step down transformer, rated for 550VA. If you are interested to find out the gory details of what would happen if there was an SMPS there instead, I'll happily oblige next weekend. But, back to our hero. For the purpose of this post I'll exclude skin effect and flux density calculations, and also simplify the primay and secondary turns math.

Our hero will require a core capable of 550VA, operating at a frequency of 50Hz.

This is the first difference, because in the US the supply is 60Hz. That is a 20% difference in operating frequency, and a 50% reduction in the primary voltage, a significant reduction in flux density. This generally means that similarly rated cores in the US can be a little smaller than the 50Hz cores (this is also why transformers in SMPS units are so small, they operate at a very high frequency). This however does not impact significantly, the operation in reverse.

I need to target a current draw of 2.3 amps from the mains, so assuming a 60% efficiency, I increase that to 4 amps. Then I need a primary impedance of roughly 57.5 ohms, which is nicely achieved by about 750 turns of 28AWG wire. Since Raghu will know exactly what I'm talking about I'll not detail it further, but for those of you who are confused, please PM to find out more about this calculation.

Now, I need 375 turns on the secondary, and I'll specify 24 AWG which gives me a secondary resistance of 11.325 ohms, give or take. I'll have regular class II insulation as I don't expect the hero to hit above 100 degrees (assuming I've calculated the core correctly, in this case I have not done all the back checks on core size and saturation - but IME as rough calculation it works fine). This is a pretty big guy, should be about 4 inches tall by the same wide, haven't figured out the depth yet as that depends on winding density.

When I connect it to the mains, what happens is that the mains (at idle) will see a winding of about 60 ohms, and given that full load is connected, will deliver about 700 watts to the winding (simplified).

Now, we want it to step up the voltage, so we reverse the connections.

Now the mains is looking into half the turns, and 1/6th the impedance. 11ohms across the mains = 4.809 kilowatts.

I'm bad at maths, but that is a seriously heavy load.

However, this is not the amount of power really drawn.

The real power is the leakage, plus the load, and you have to factor in efficiency (60% is what we had specified earlier).

So for a 550 watt load, we are looking at about a kilowatt of power in that core, and about 10 amperes of current through the now-primary winding. But nothing bad happens just yet, except it starts to warm up. Mind, 10 amps is still within the wire's current limit, but now we have a third factor: Temperature.

After about 15 minutes, this core will be at 110 degrees (assuming a 4inx4in EI laminated core). At this temperature, the wires connecting the transformer will have much softer insulation, but we're still in a comfort zone.

After 30 minutes, the temperature will reach about 150 degrees. At this point, the varnish used to coat the laminates will start softening.

After 60 minutes, this will reach about 180 degrees. Any connecting wires will have melted insulation, creating a potential short circuit hazard.

Varnish will vaporise at this point, causing the laminates to touch, and reduce the core impedance.

This will lead to further current draw.

To not belabour the point, soon there will be an effective short across the core. Cheap transformers don't survive these conditions for very long, the enamel in the copper breaks down and creates shorts within the trafo, but well-made guys can hold out till 250 degrees plus. But eventually...

FIRE!!!!

If we're really lucky, the wires inside will open circuit and there will be no primary draw. If we're unlucky...

Now, if there was an SMPS inside, and it was opened, it can kill someone is seconds. Let me know if you need another dissertation on exactly why.

There's always a nice way to talk to people without being sarcastic, rude and arrogant. Maybe one day we will all learn to do the same, myself included.

Have a nice day, everyone. Anyone wanting a more technical description and a more accurate design (this particular one is full of errors and simplification) can always chat on PM with me. This topic has gone far enough OT as it is.

Warning: DO NOT FIDDLE WITH MAINS VOLTAGES WITHOUT KNOWING EXACTLY WHAT YOU ARE DOING. CAN RESULT IN SERIOUS INJURY OR DEATH!

hyeah:

hyeah: I cant do a market survey. And I didnt miss it, I just left it out of the argument.

I cant do a market survey. And I didnt miss it, I just left it out of the argument.