I recently got a Corsair Obsidian 250D. The front panel of the case is a solid block of plastic and this unnecessarily restricts airflow. I do not want to tamper the original component therefore I plan to make a 3D printed version of the front panel with adequate vents.

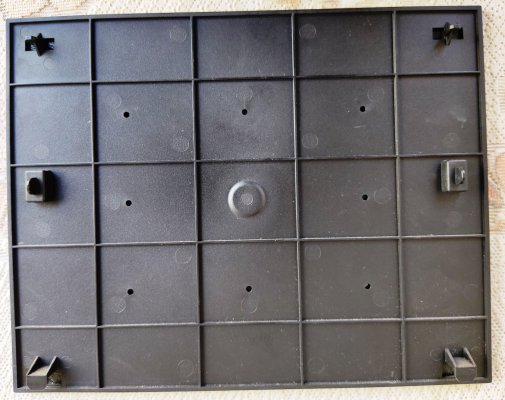

I have no idea about 3D printing so any inputs on the process and the cost involved help a long way. Also, I have no idea how to ascertain the exact dimensions of the panel in a 3D plane so any tips on how to go about it will help too. The backside of the panel has hinges which attach to the case that makes this whole piece a bit tricky.

I have no idea about 3D printing so any inputs on the process and the cost involved help a long way. Also, I have no idea how to ascertain the exact dimensions of the panel in a 3D plane so any tips on how to go about it will help too. The backside of the panel has hinges which attach to the case that makes this whole piece a bit tricky.

Attachments

Last edited: