How a dead GFX Card is made alive professionally.

In this article I will show you how a dead graphics card is repaired. No oven baking, no do-it-yourself type trikes, just a pure professional repairs.

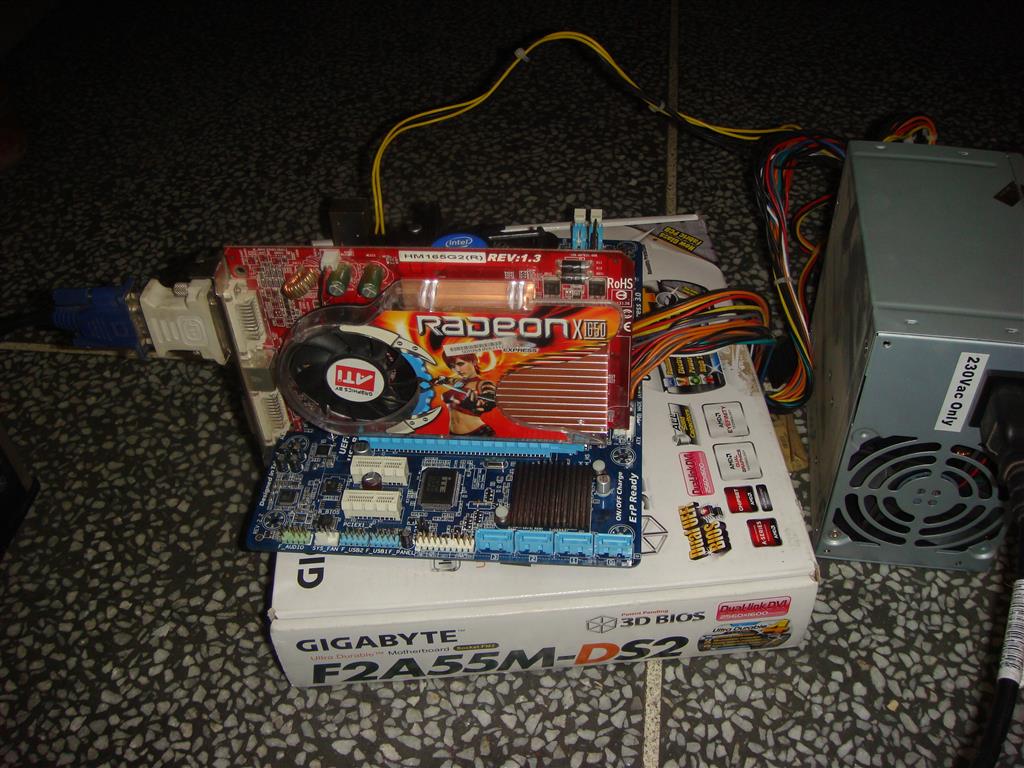

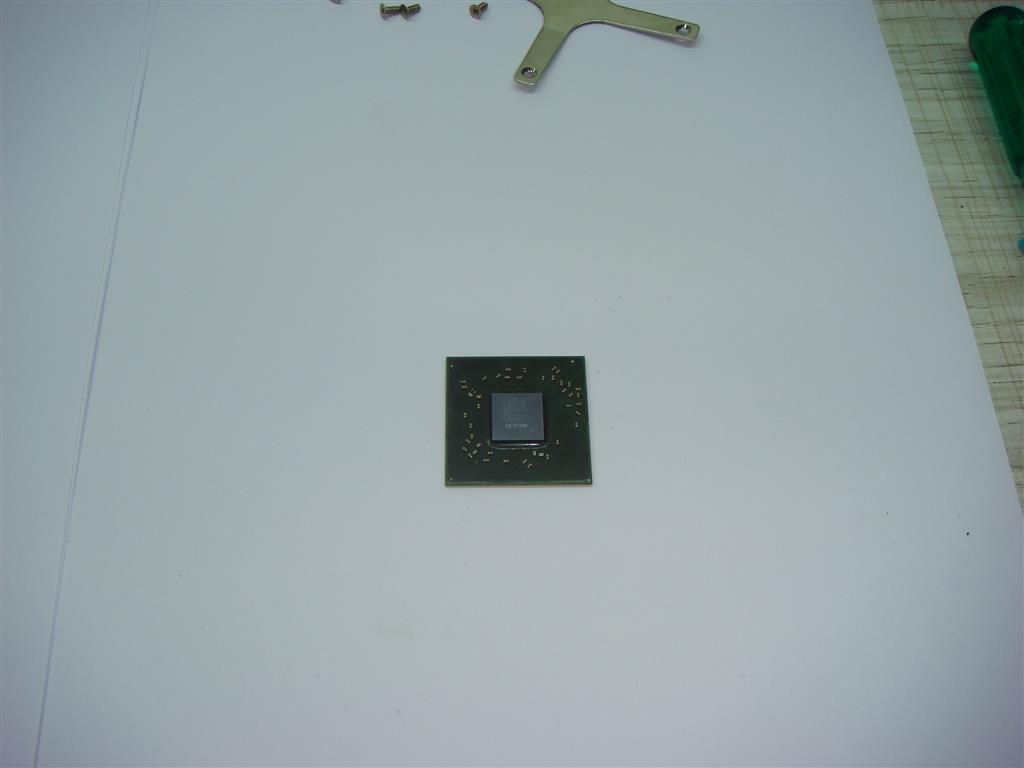

Meet the victim, my old no display, dead ATI-Radeon X1650 graphics card.

Removing the heat sink.

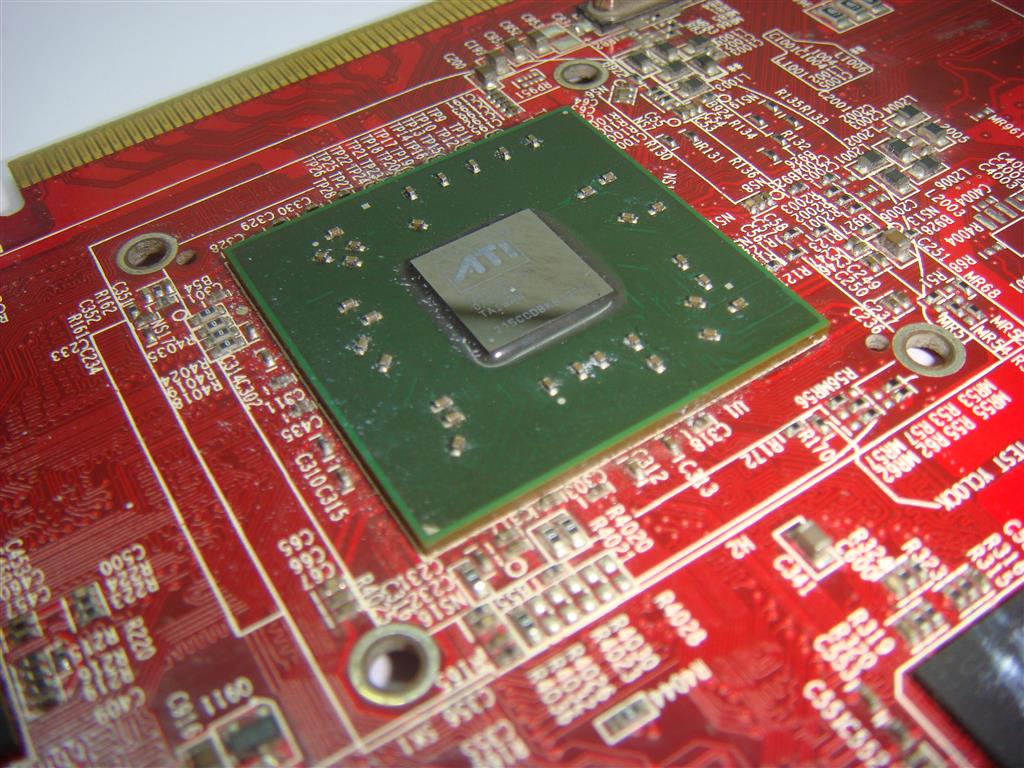

Thermal compound on the chip cleaned.

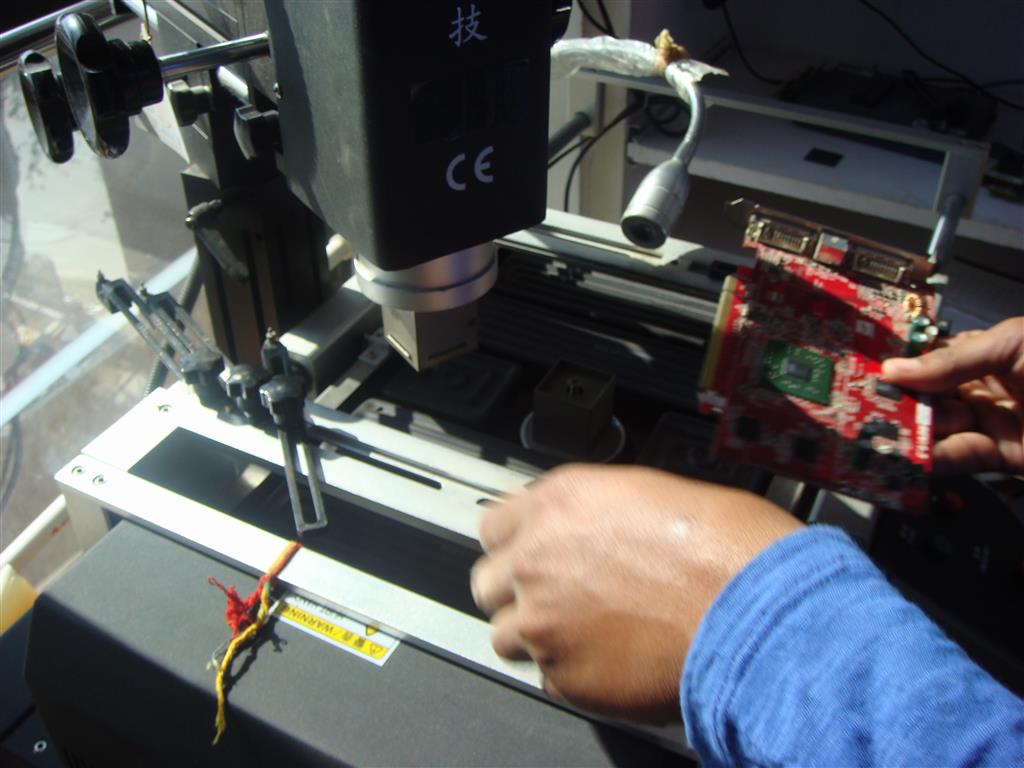

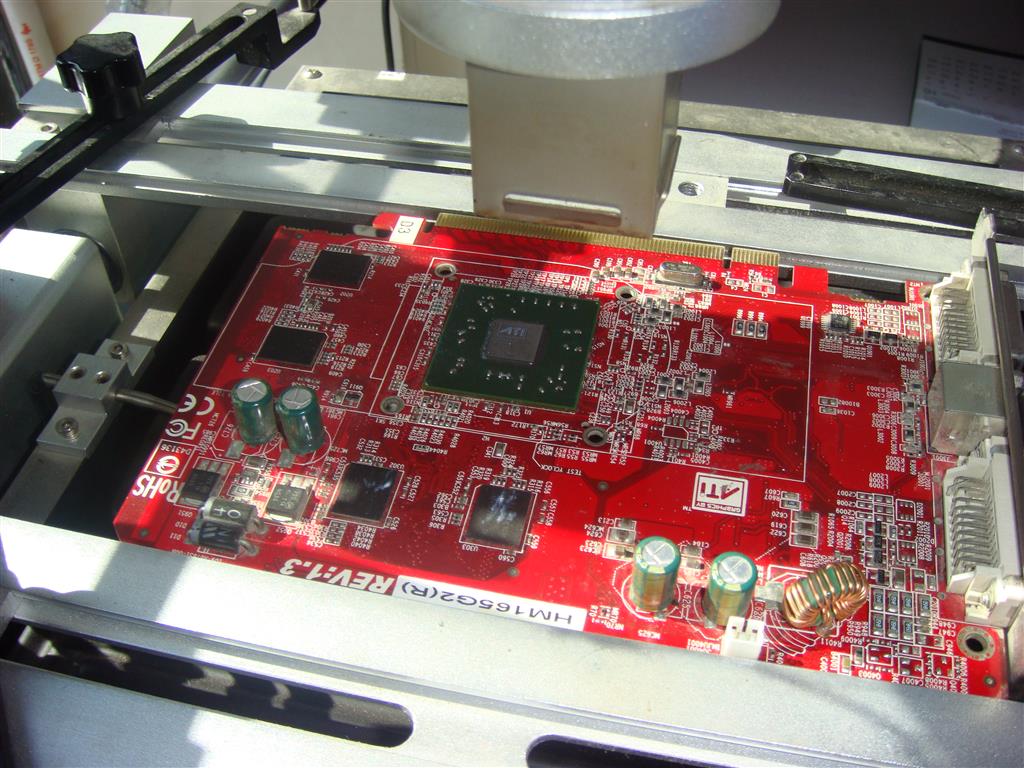

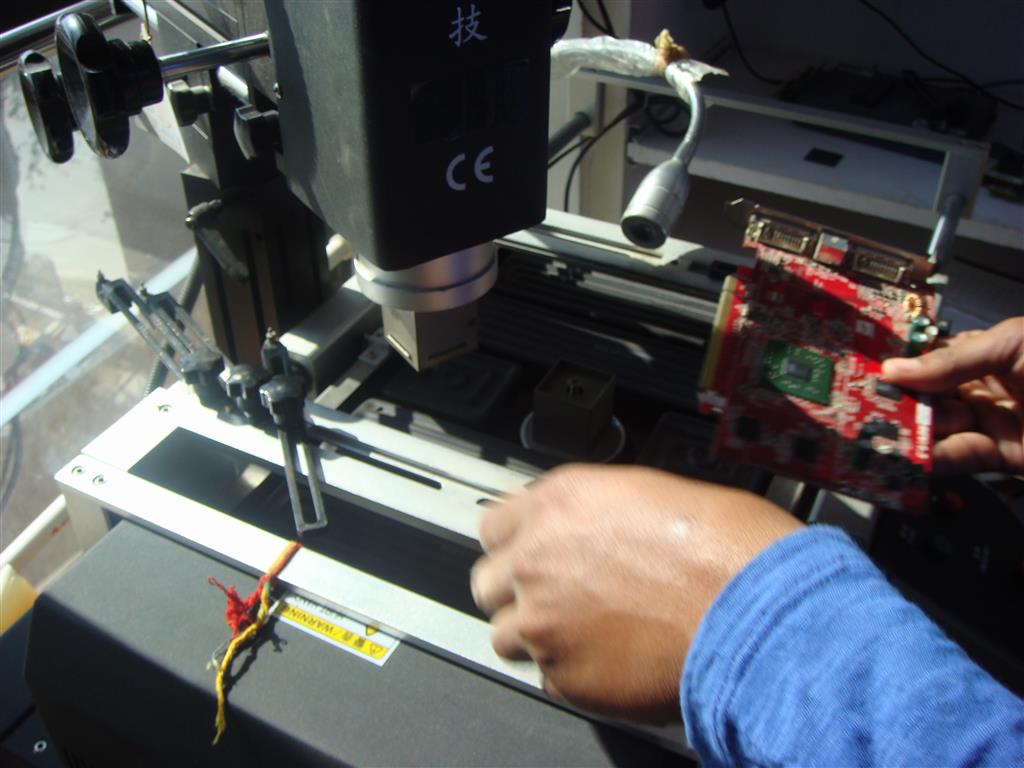

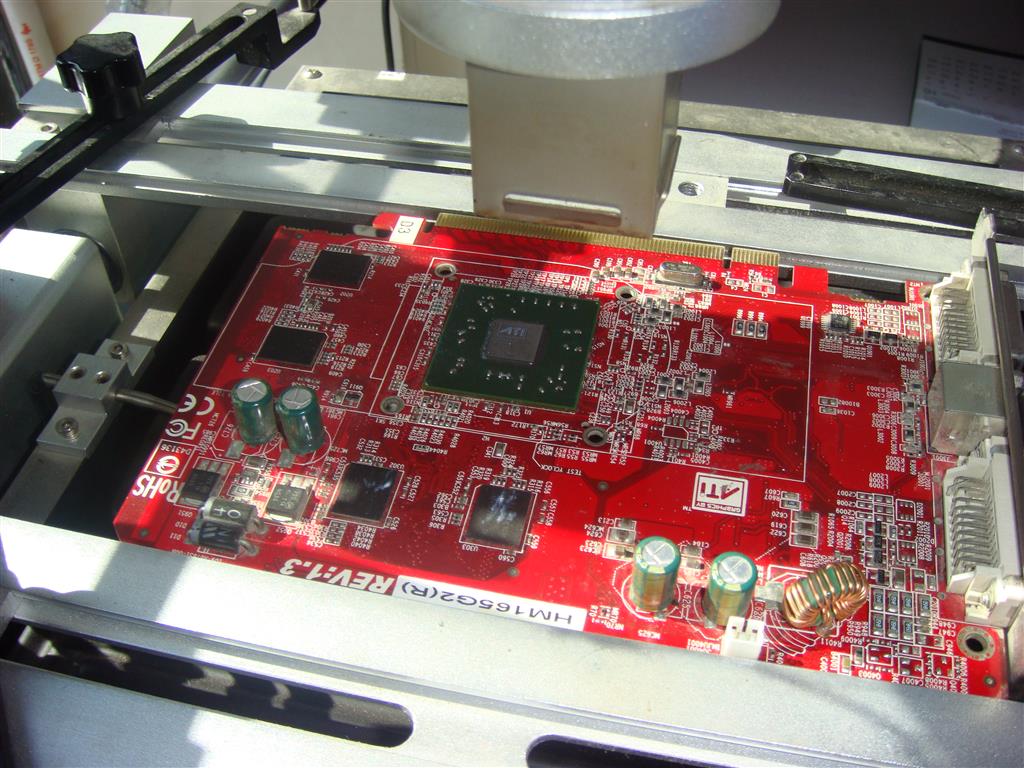

Now circuit board is installed on a BGA chip reflow machine.

Heater head mounted properly.

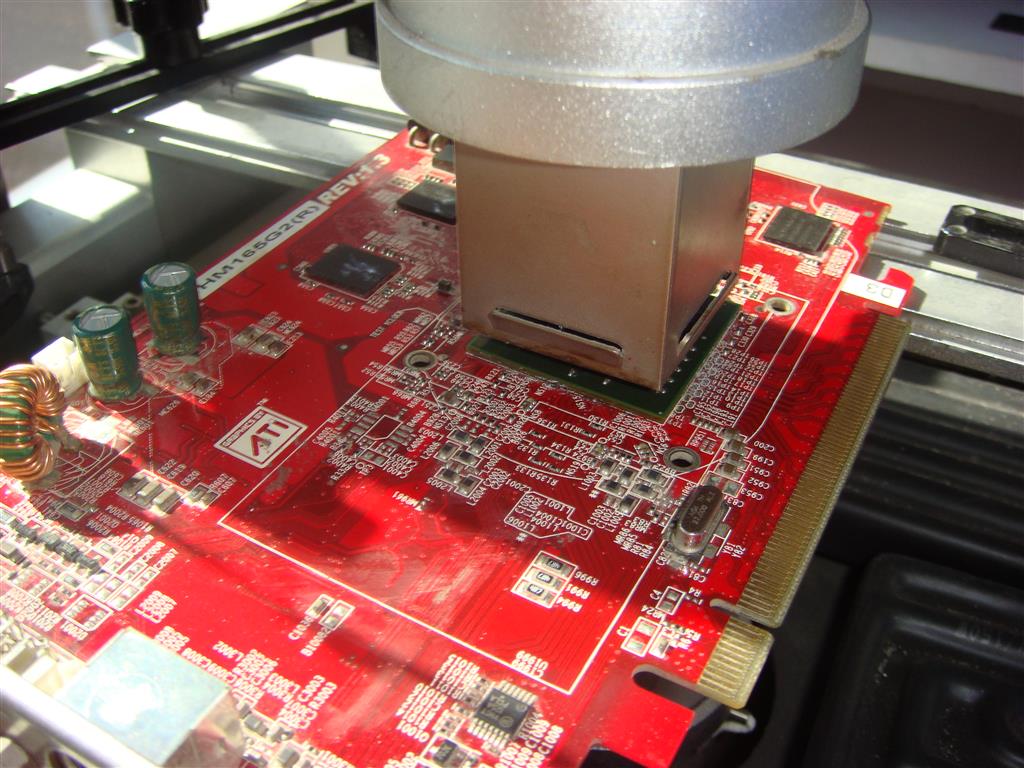

Machine in action

Within a minute chip is out.

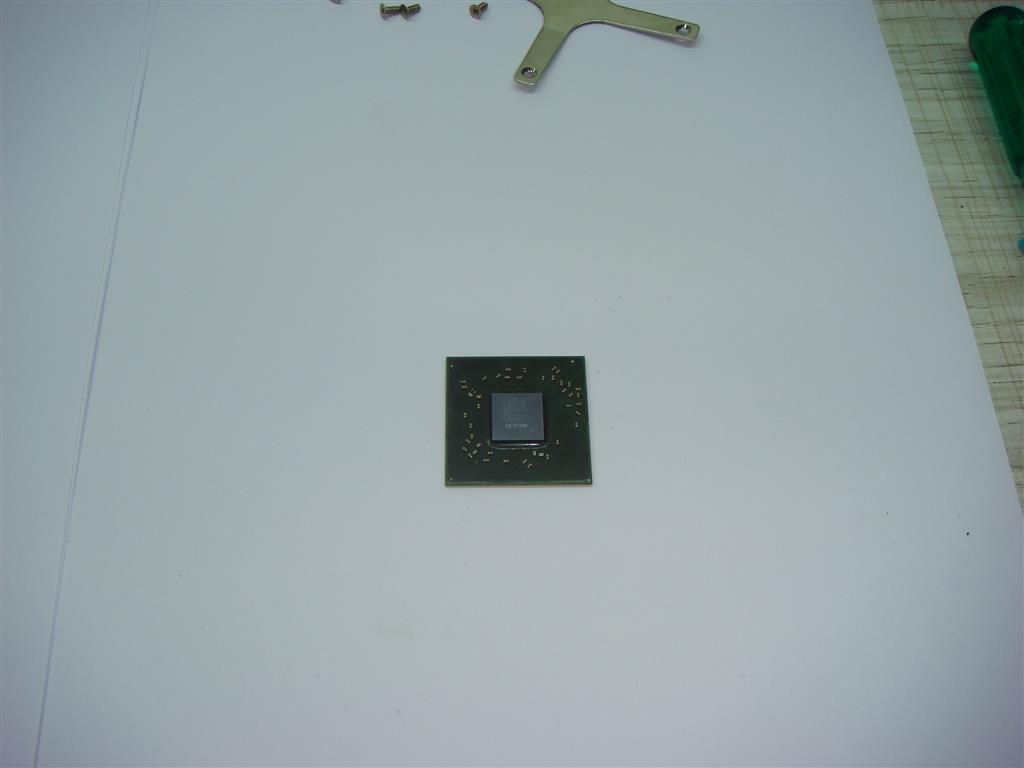

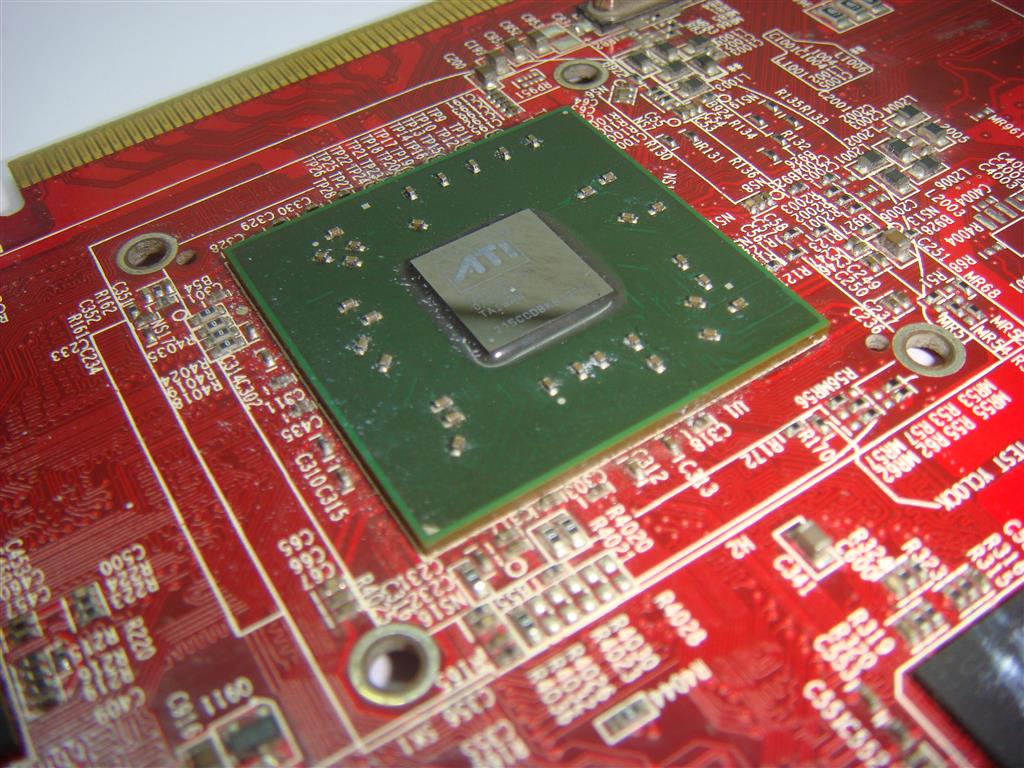

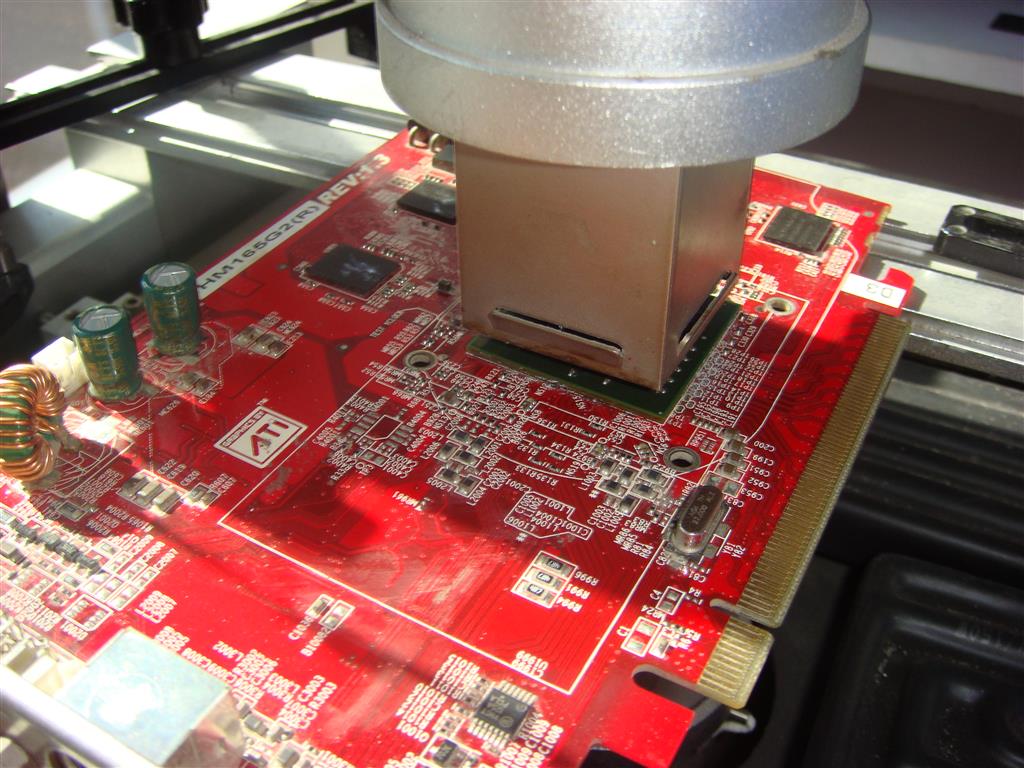

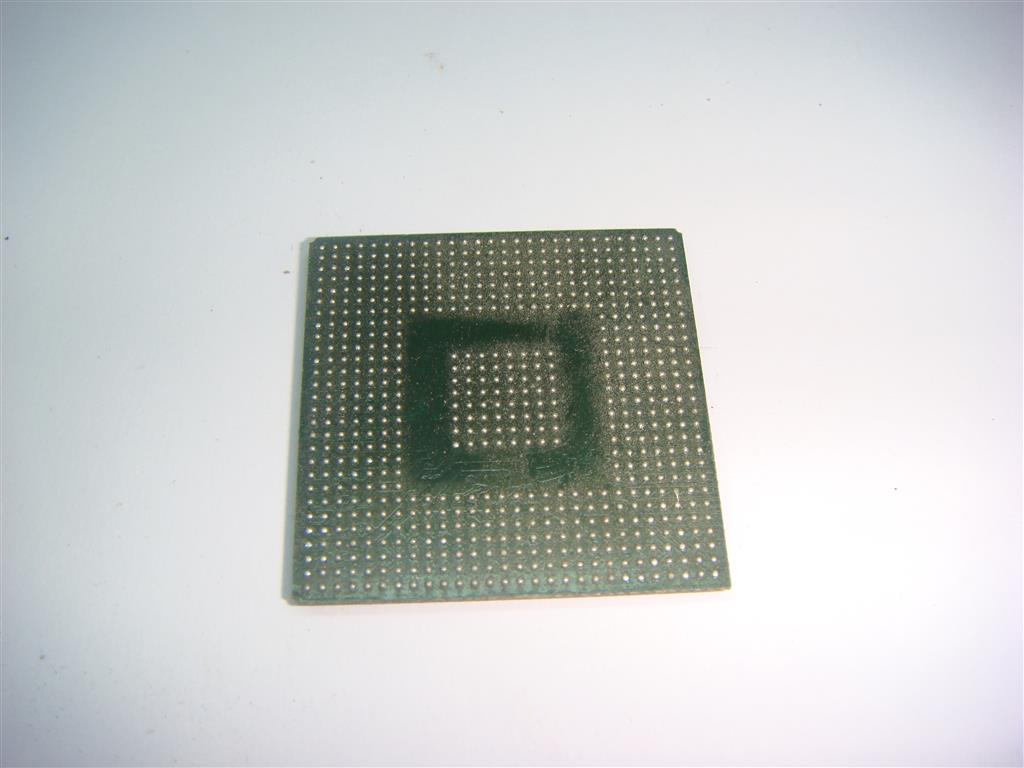

There is very little space between chip and circuit board approx. 0.1mm still you can see their is dust under the chip. This dust, heat and moisture together sometimes oxides and breaks these fine connection resulting a GPU failure.

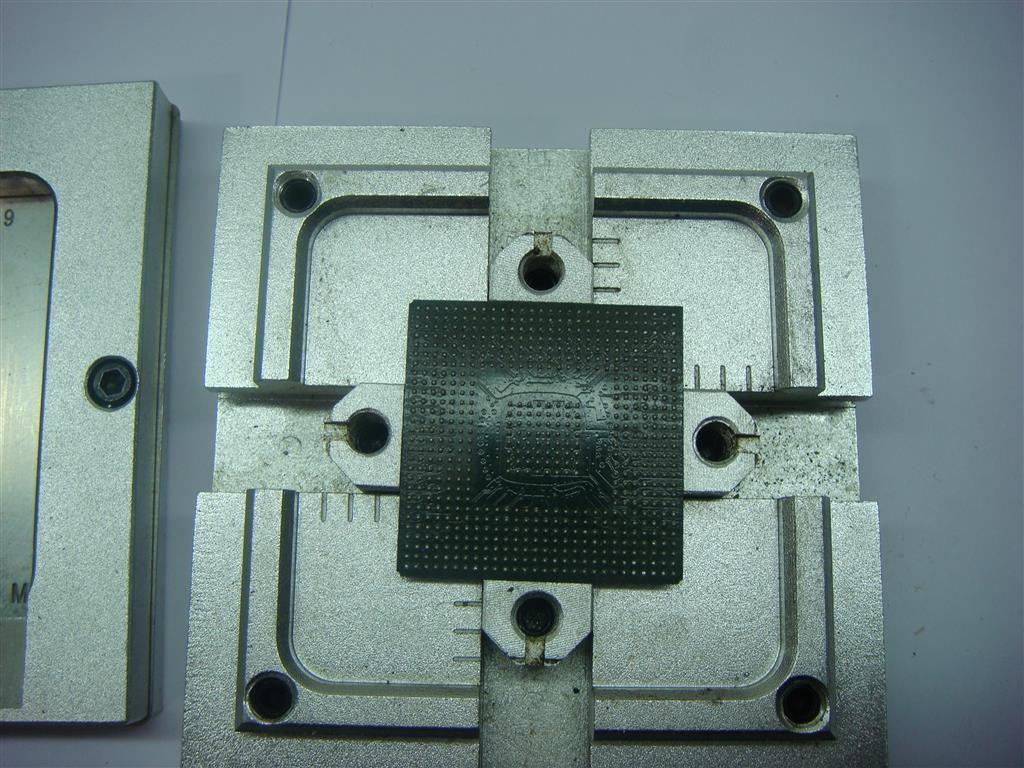

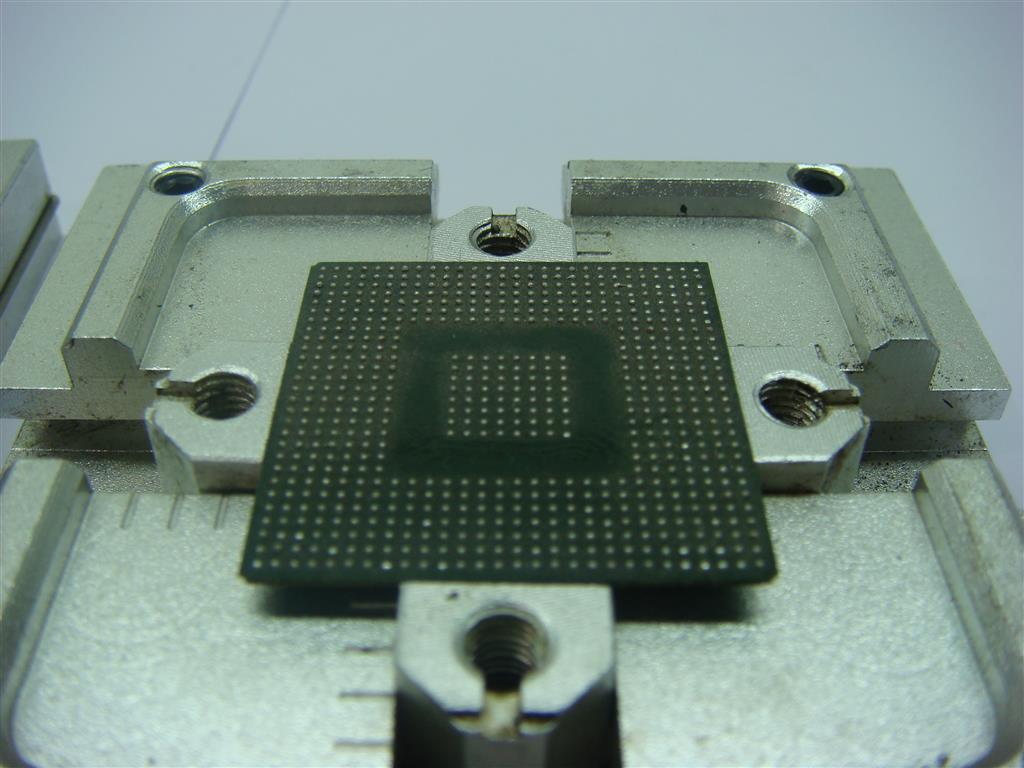

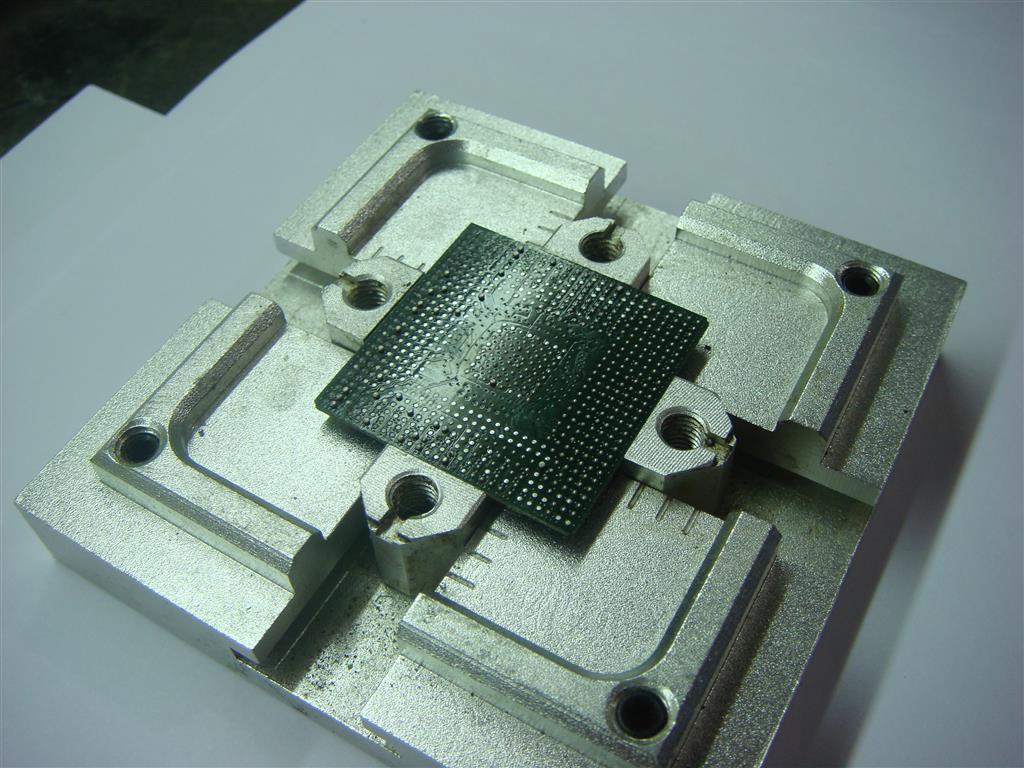

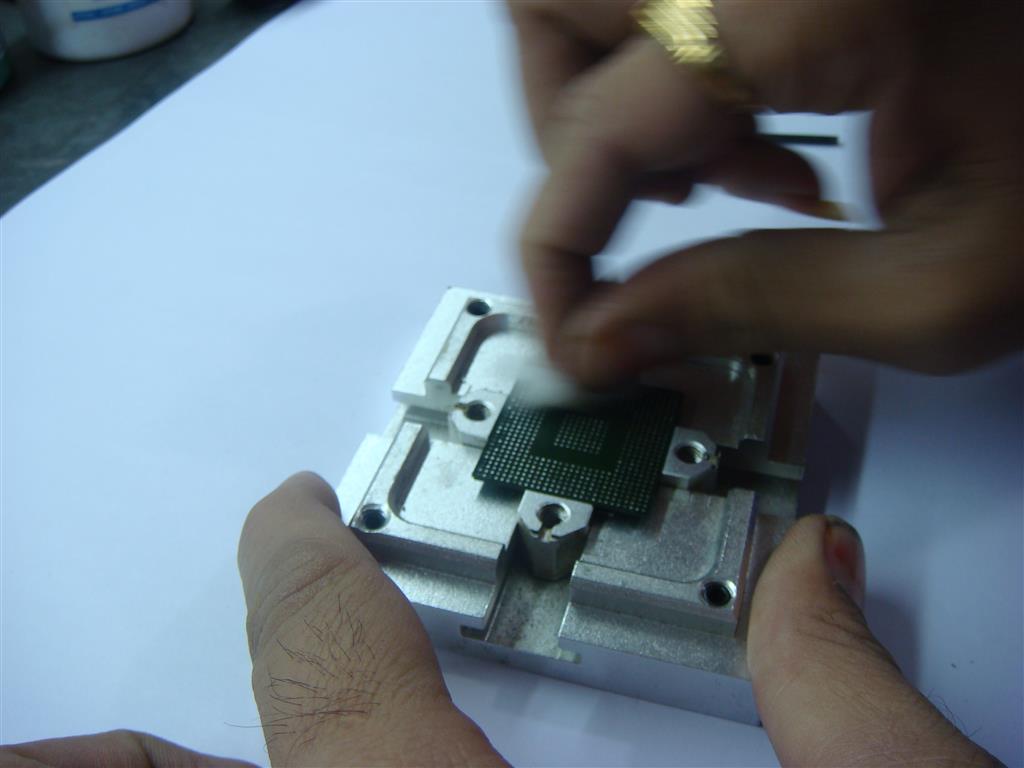

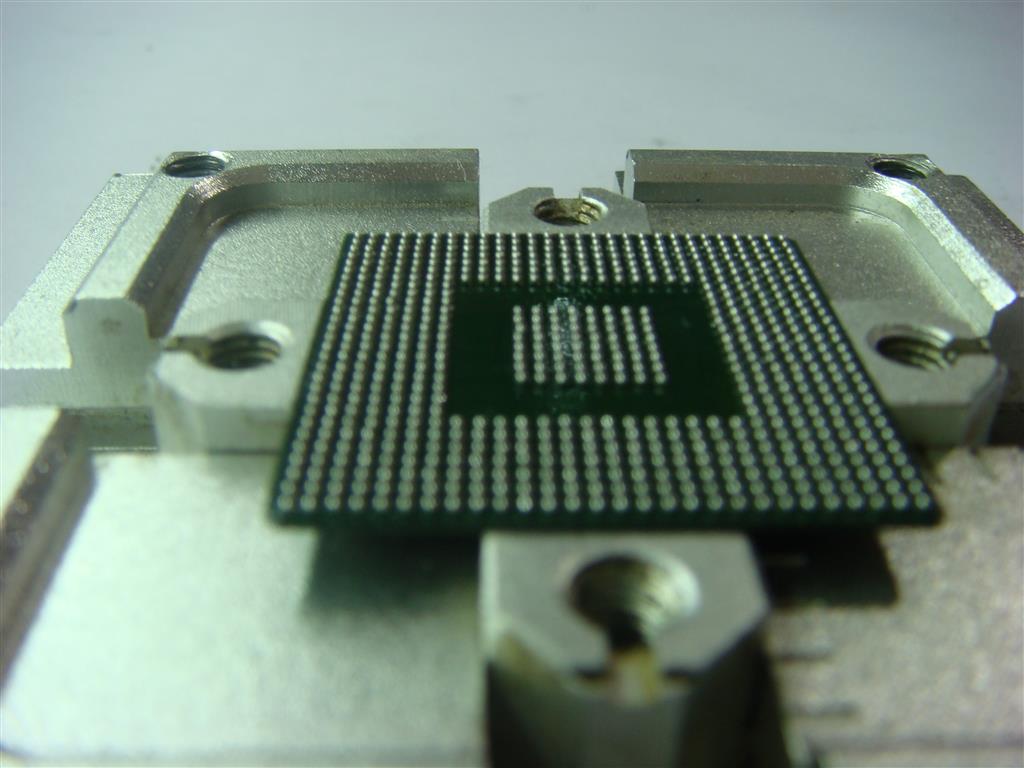

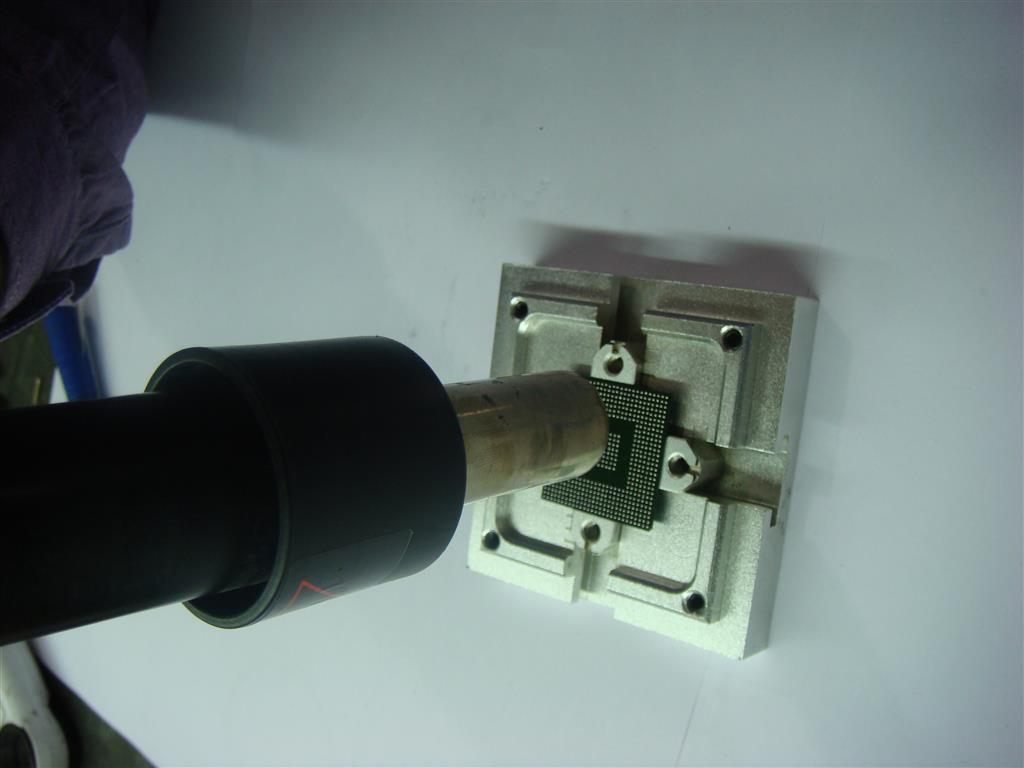

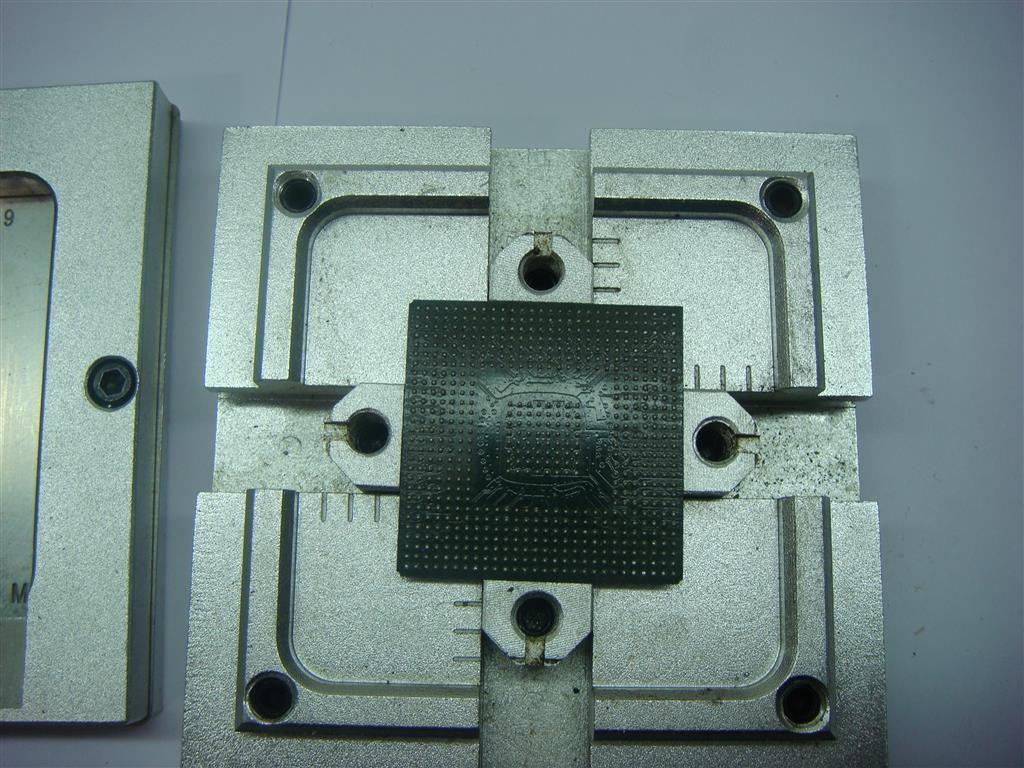

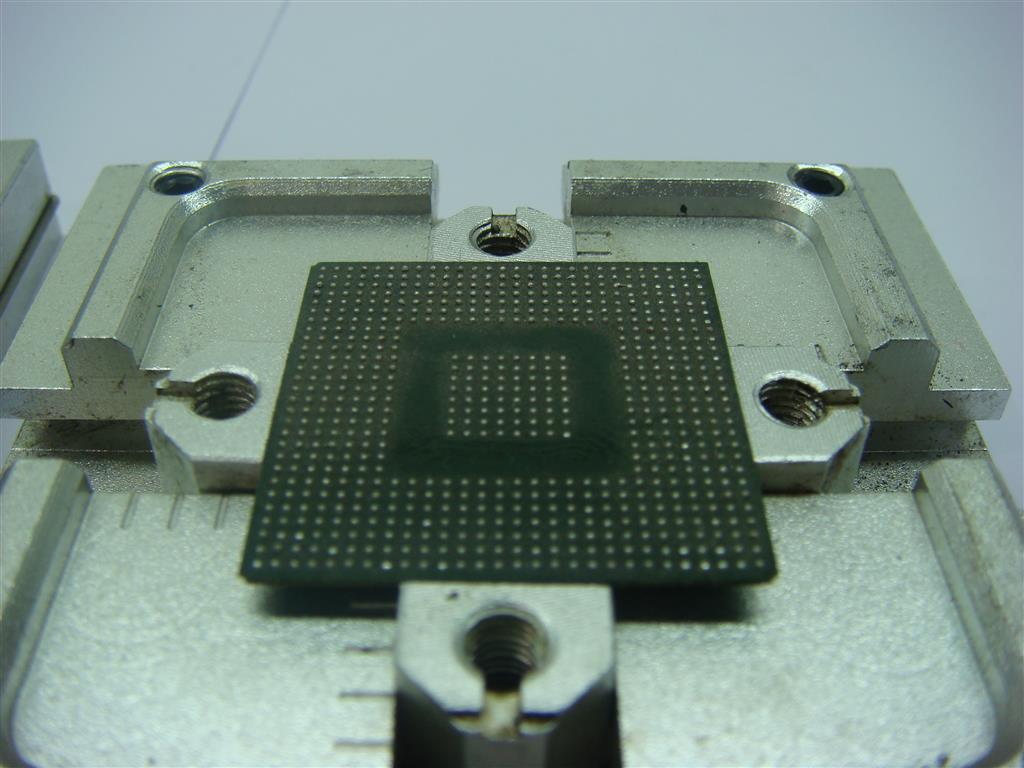

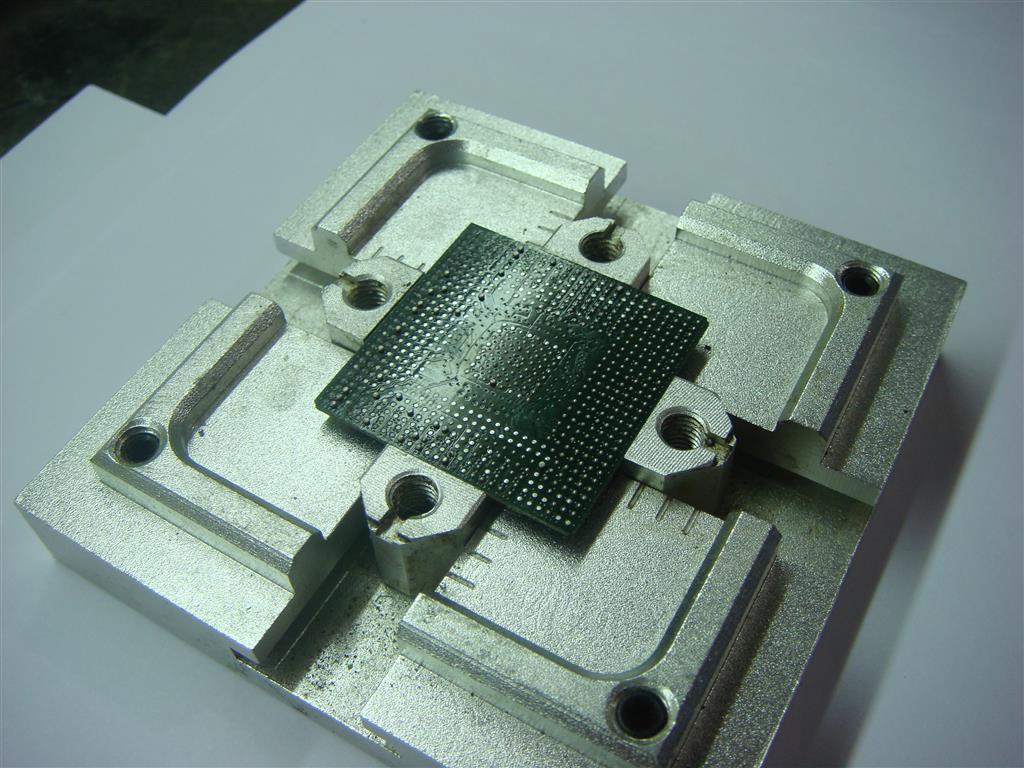

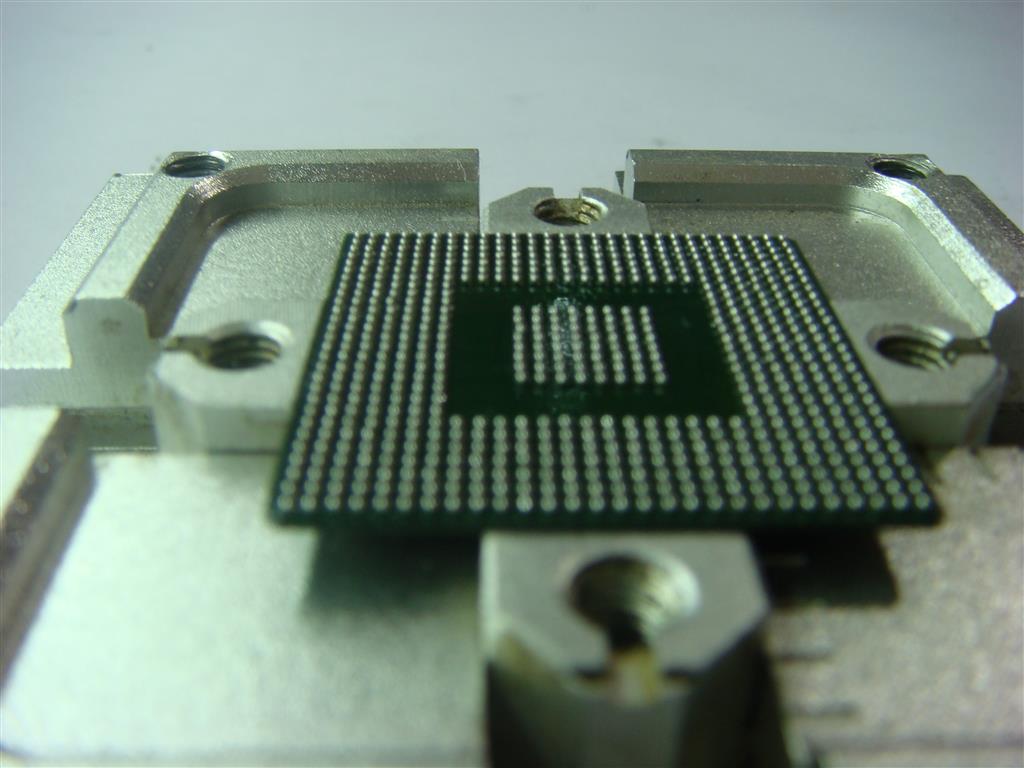

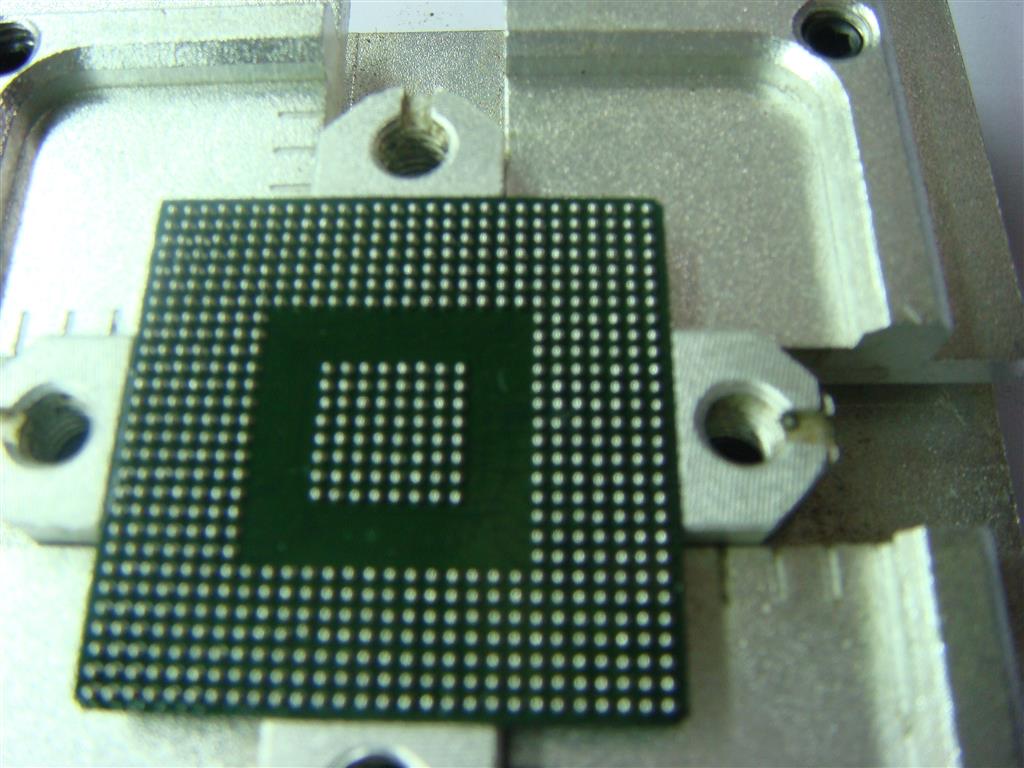

Chip is mounted on a reballing mount.

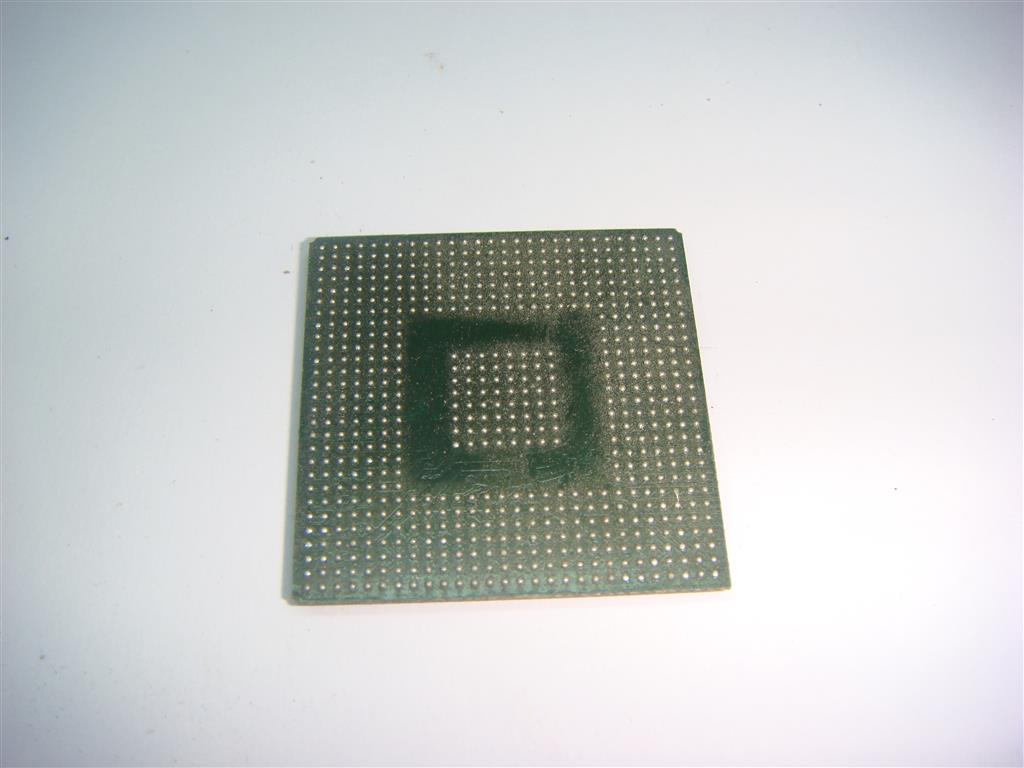

You can see many connection pins have gone black due to dust and oxide layer.

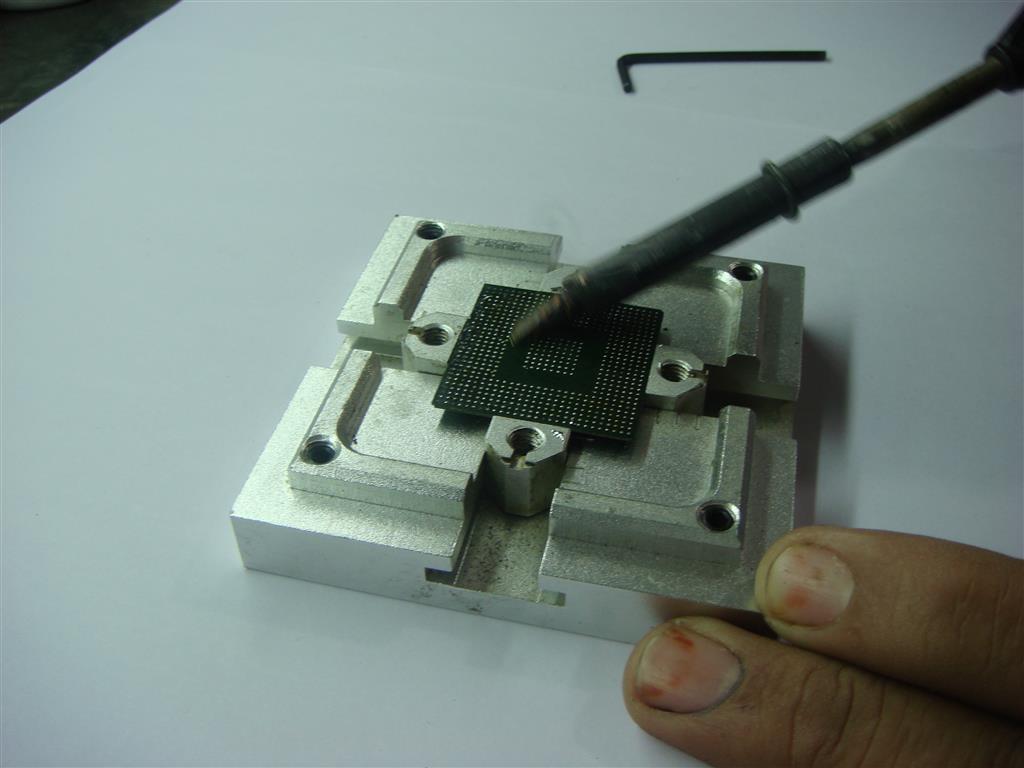

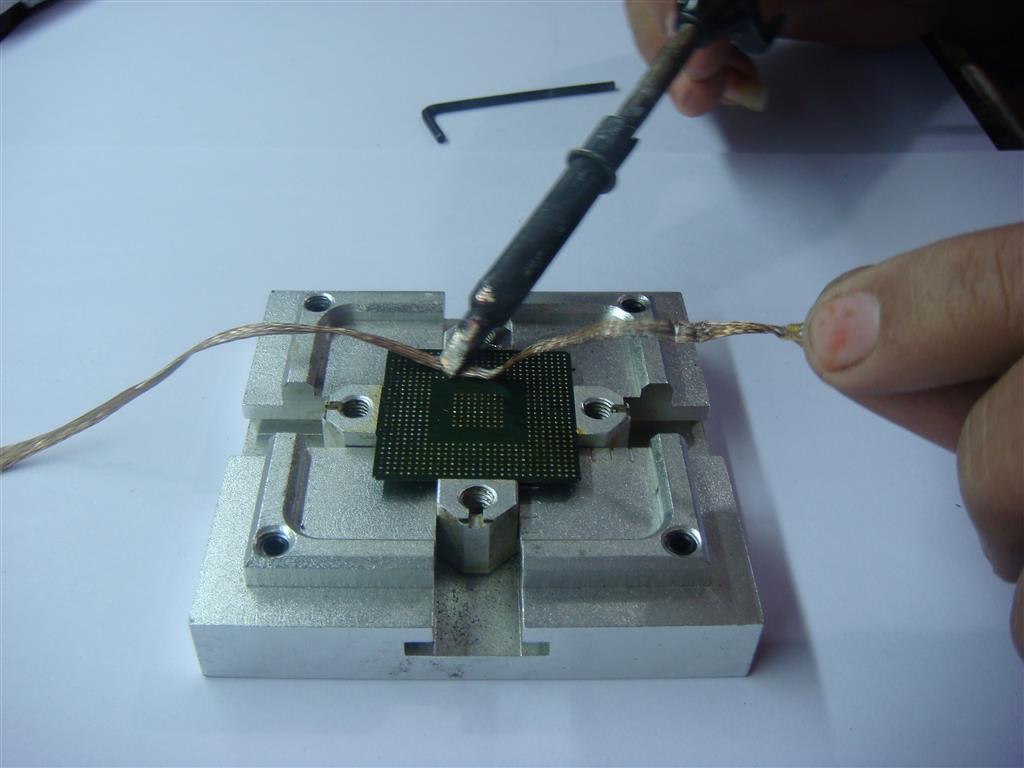

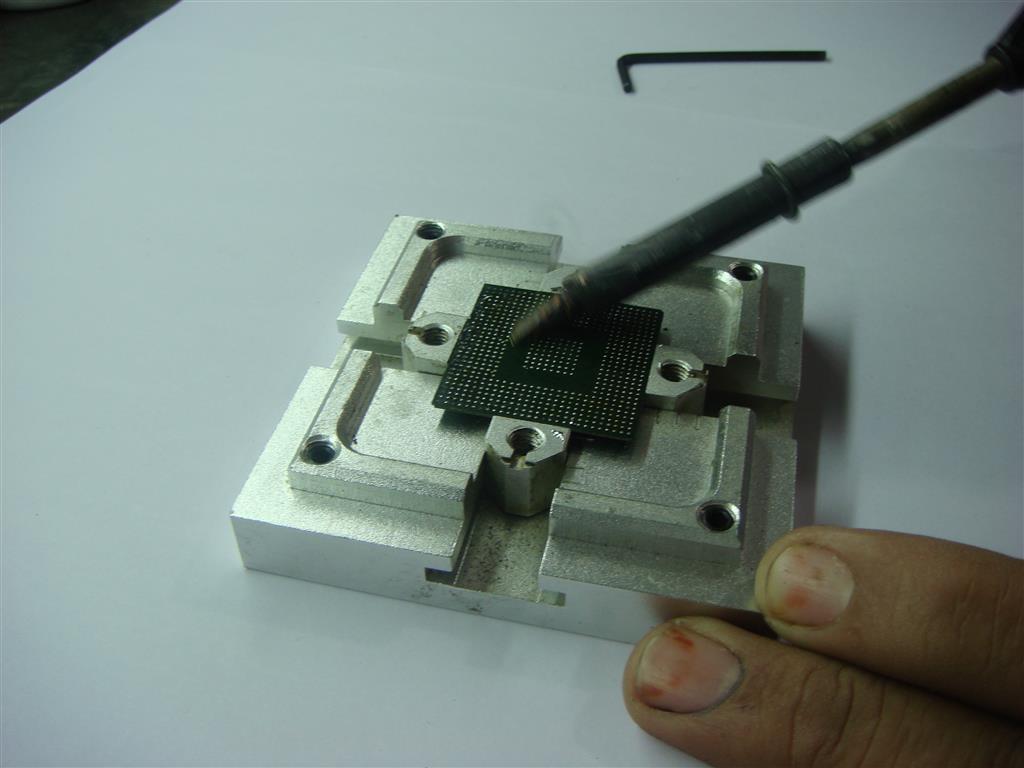

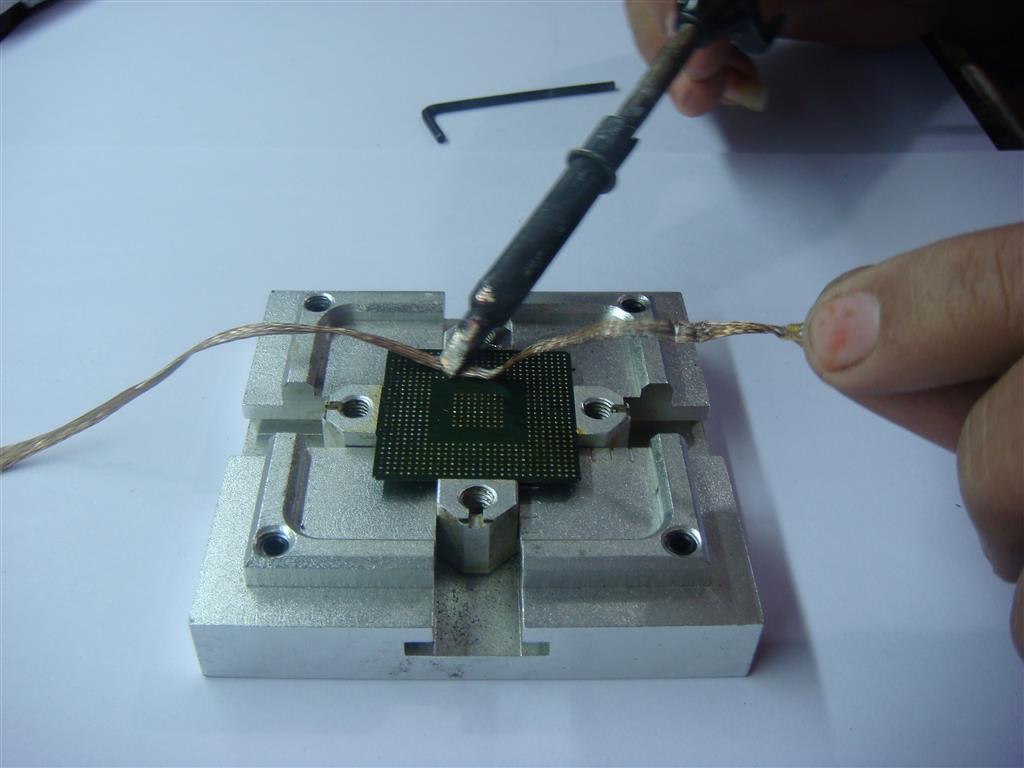

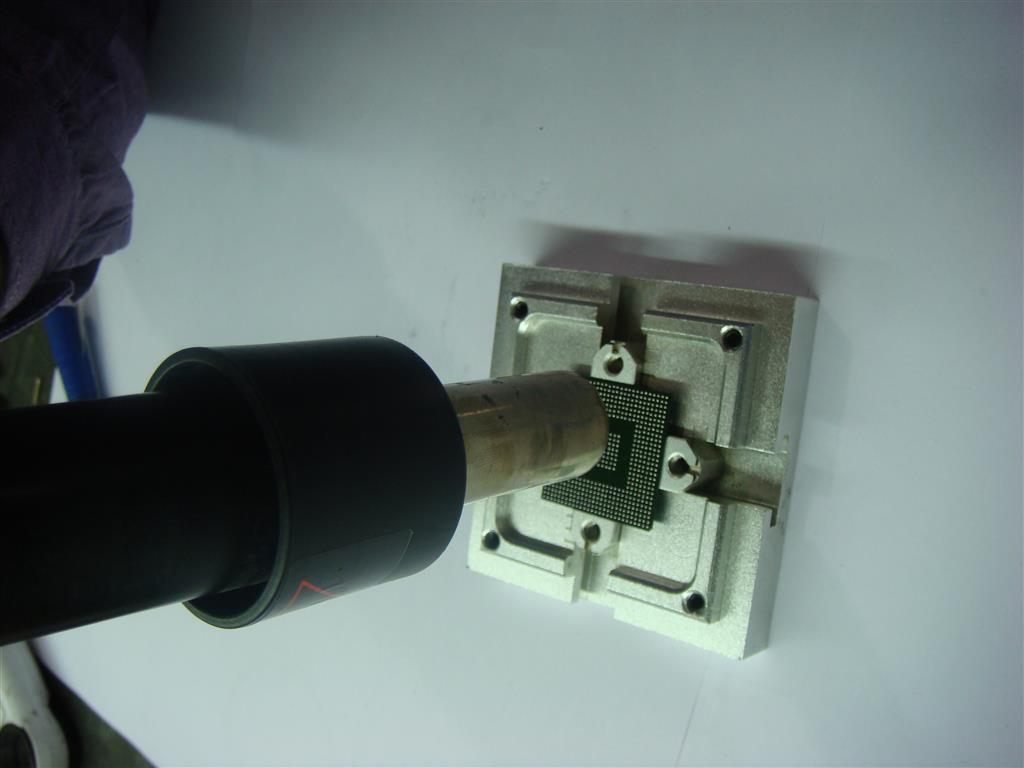

Heat cleaning the chip connection terminal.

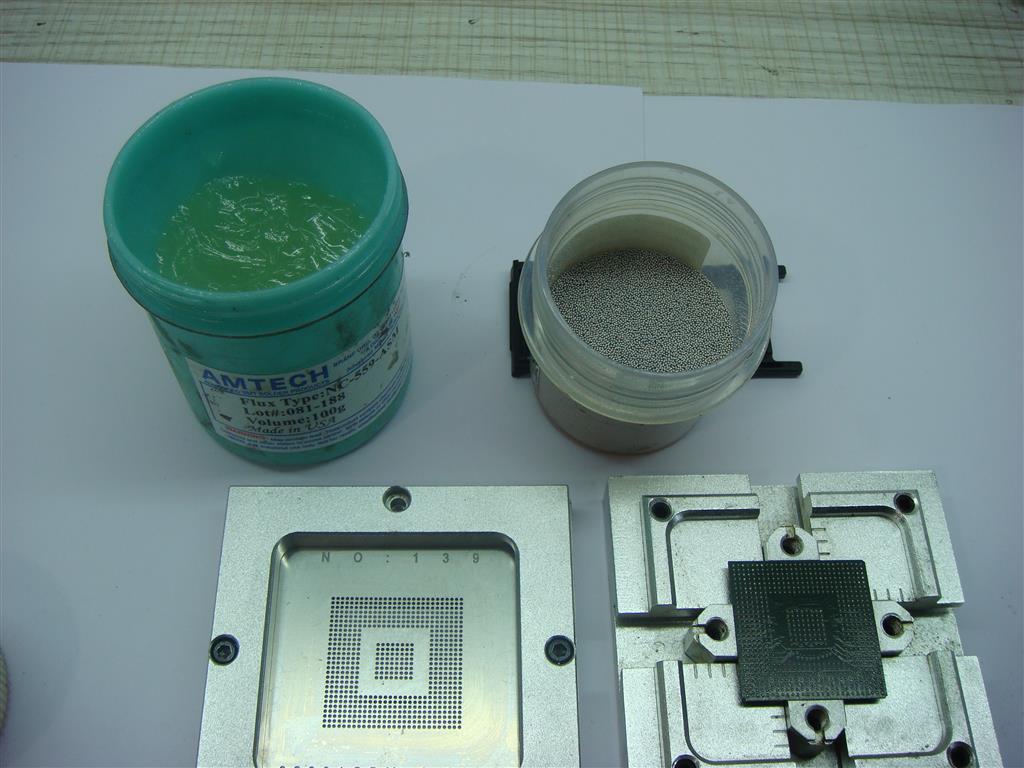

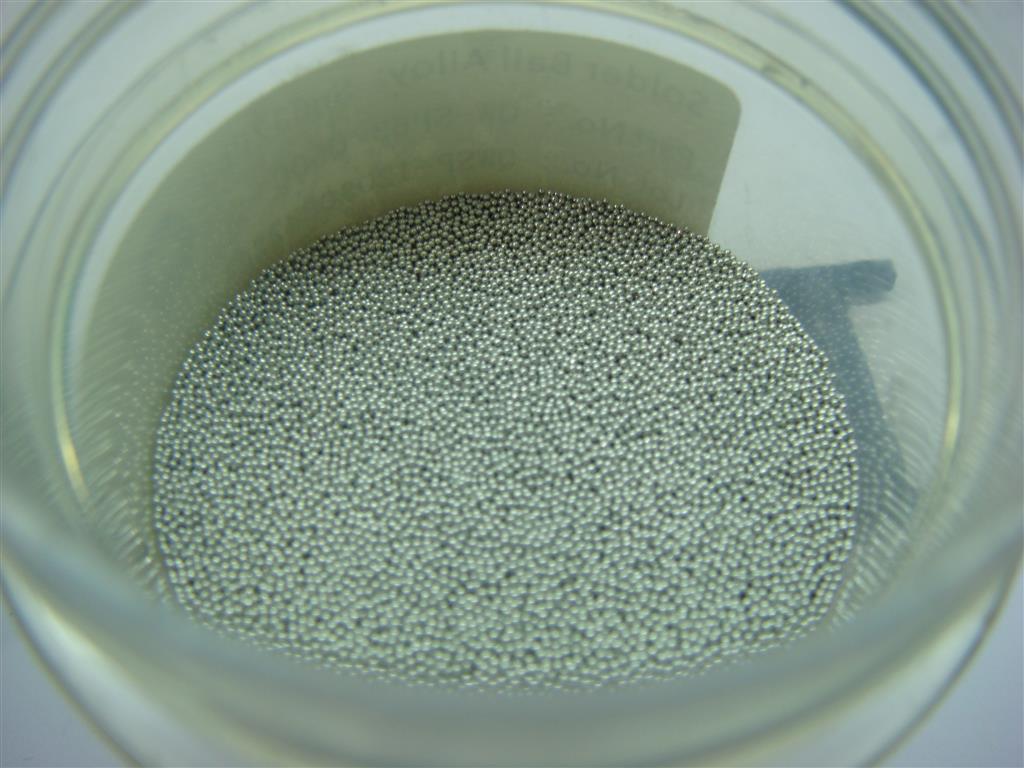

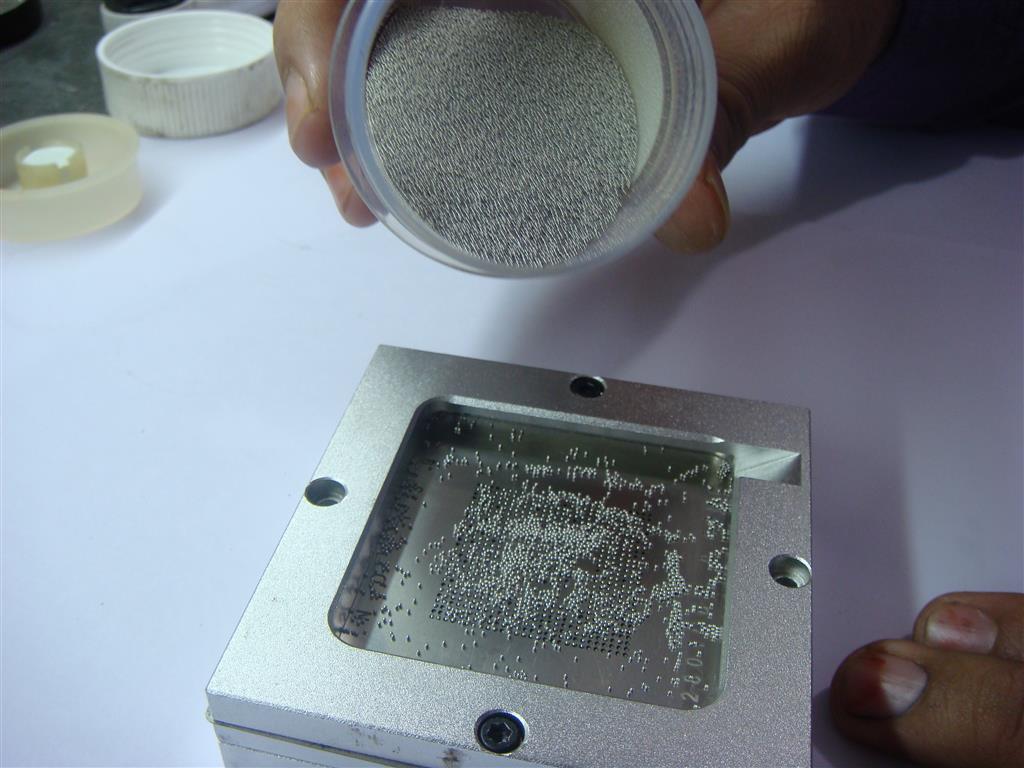

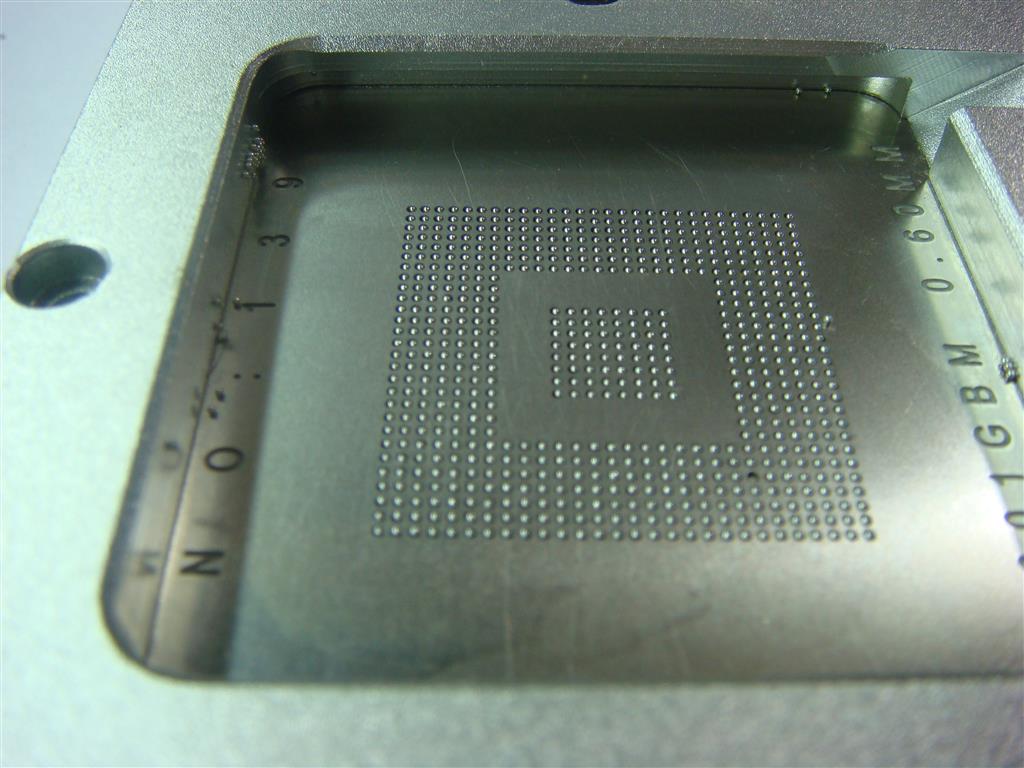

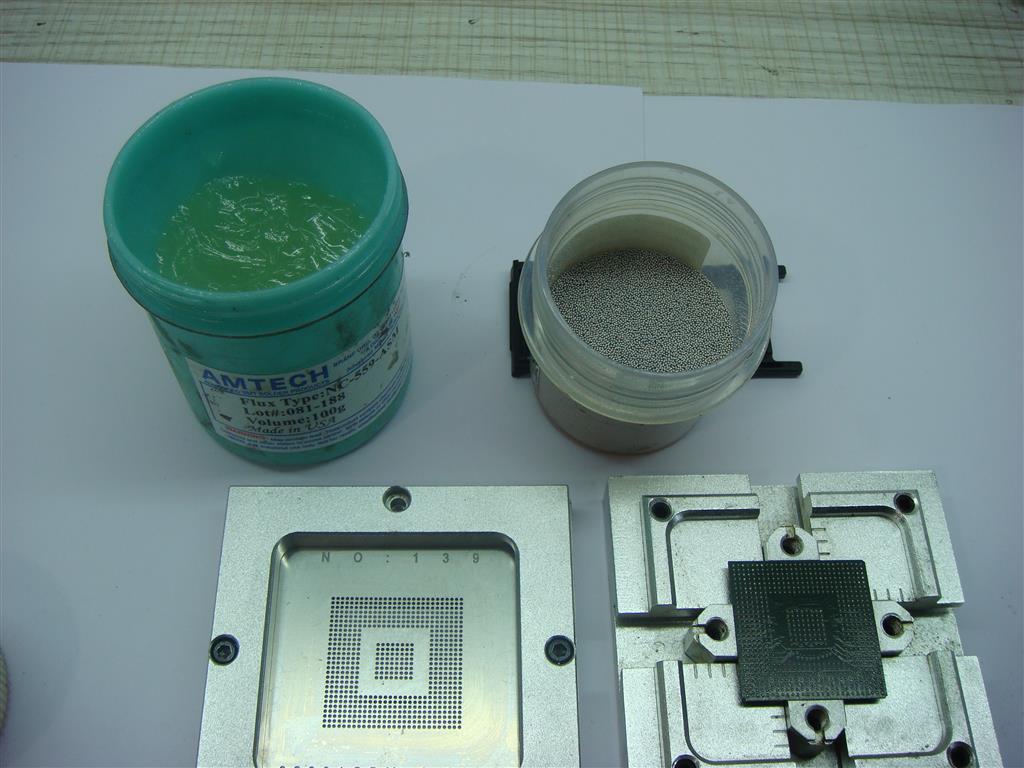

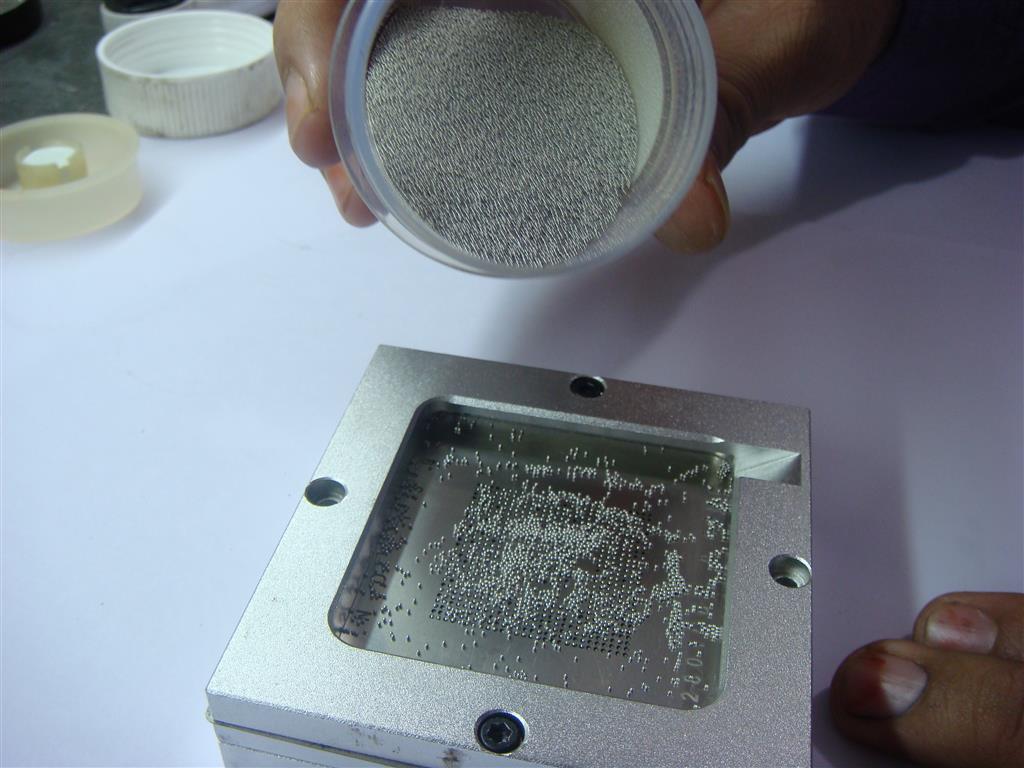

Preparing the chip for new BGA soldering balls. Flux, 0.6mm lead free soldering BGA balls and grid.

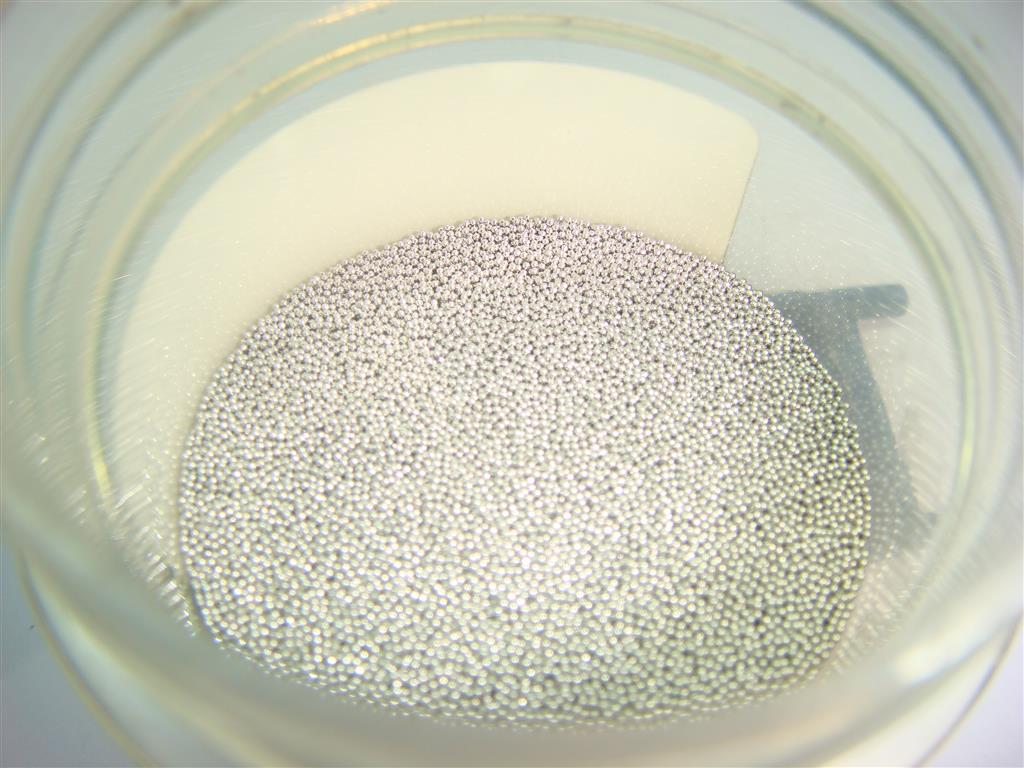

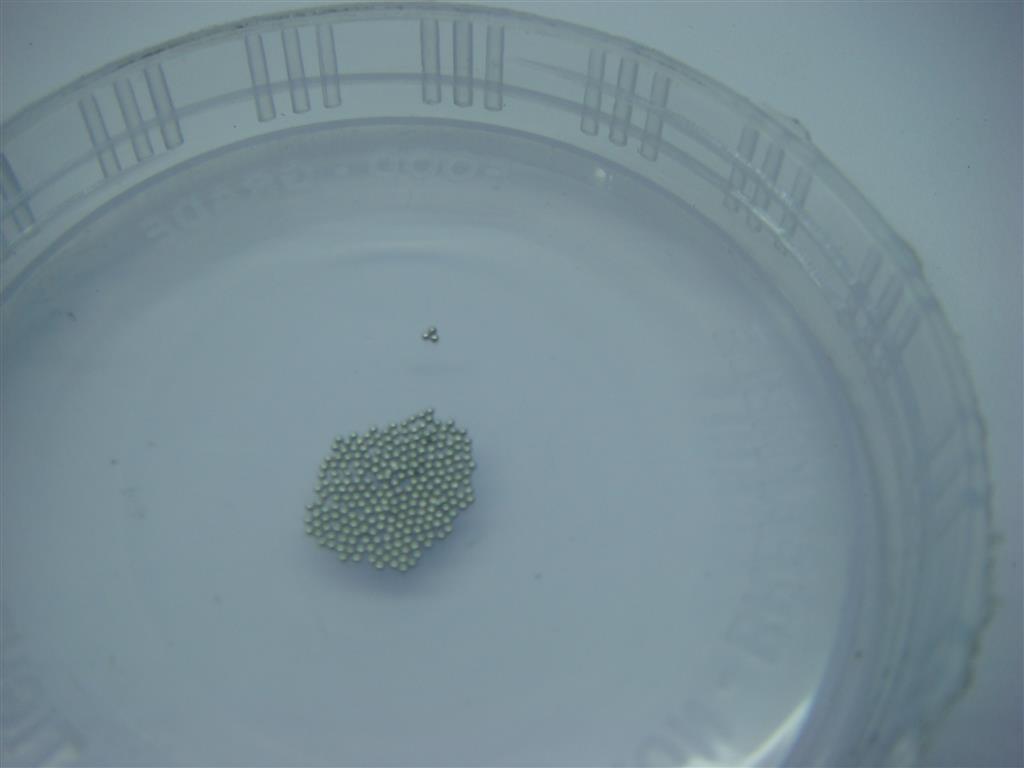

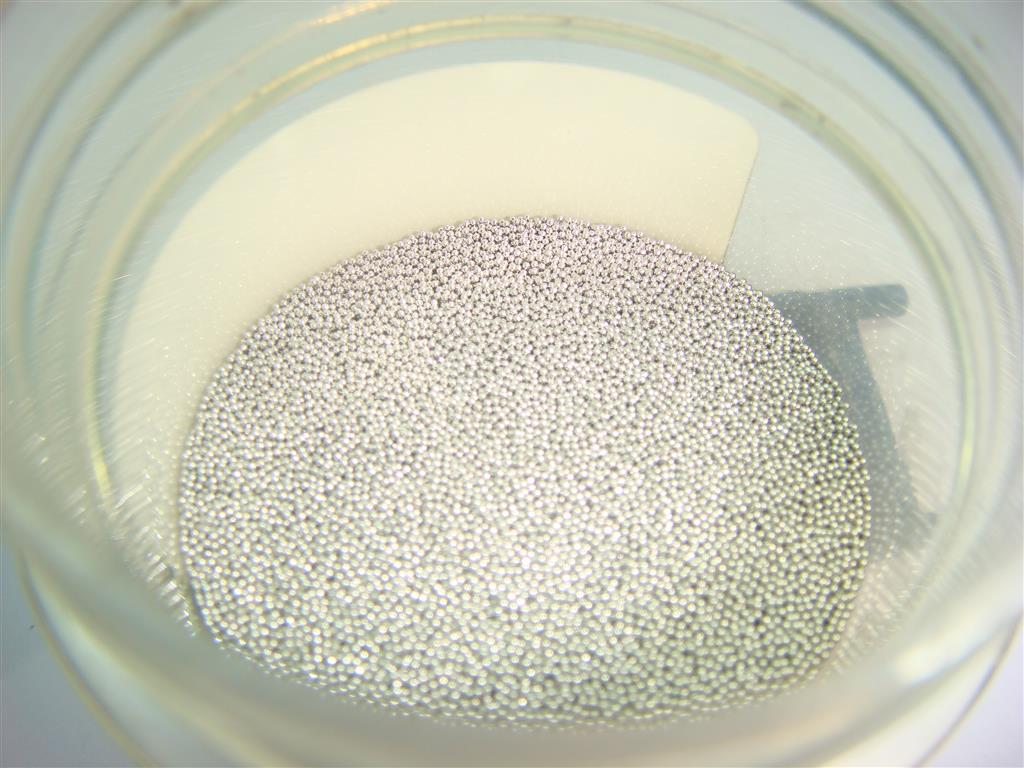

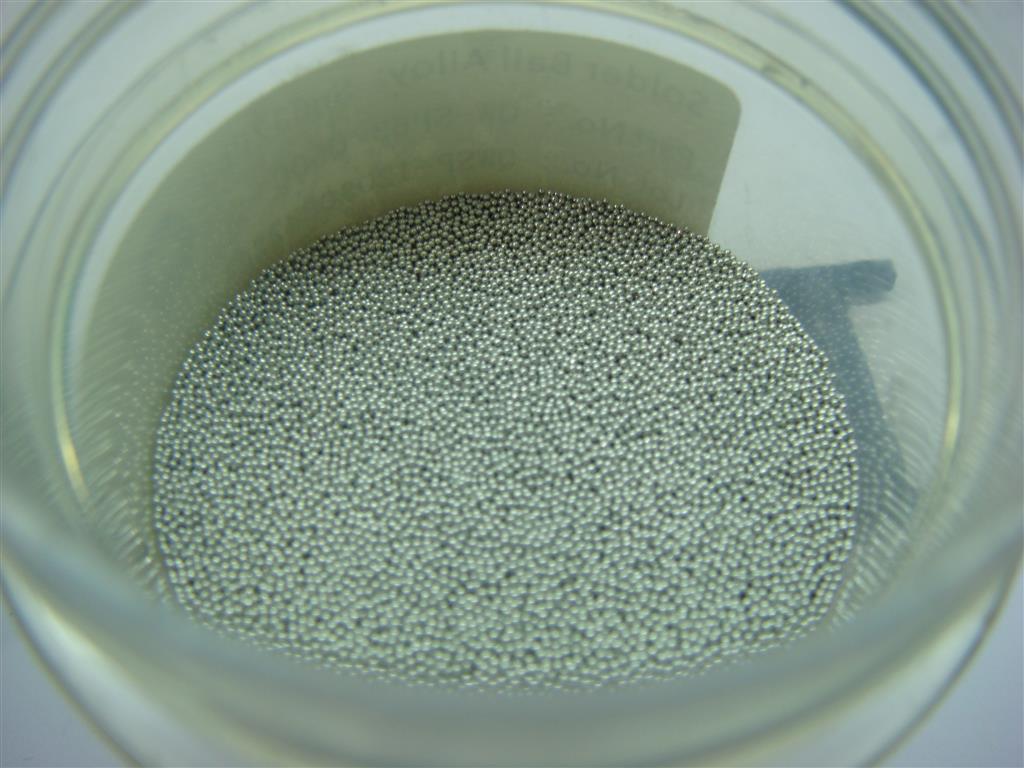

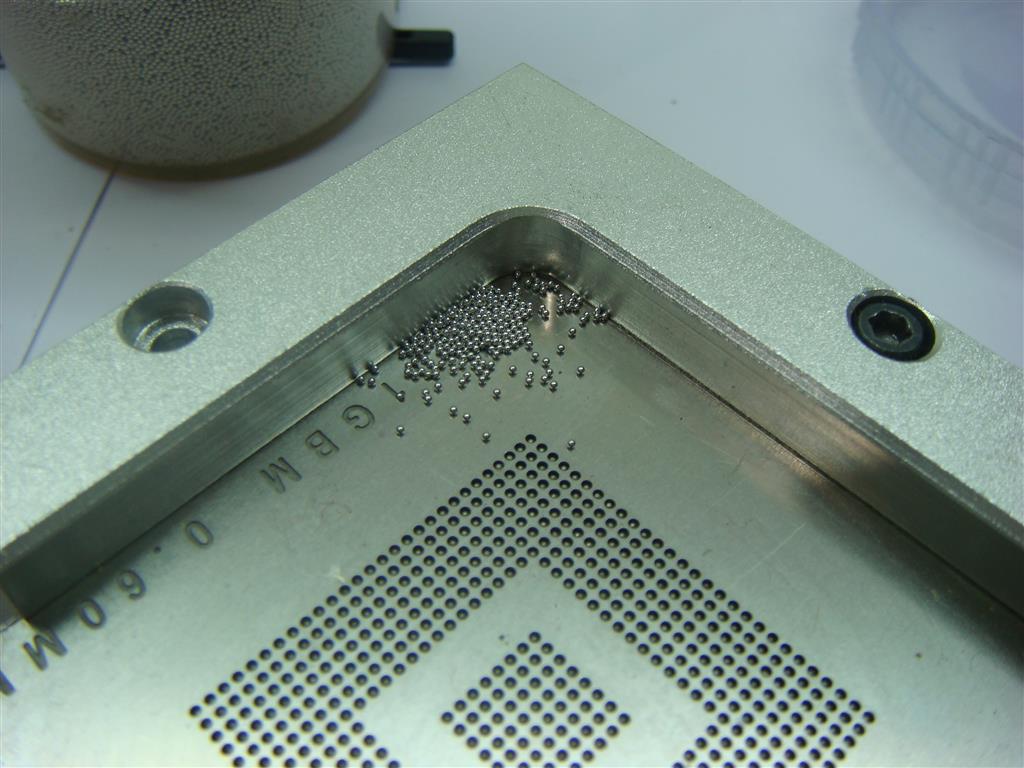

Some close look on BGA soldering balls

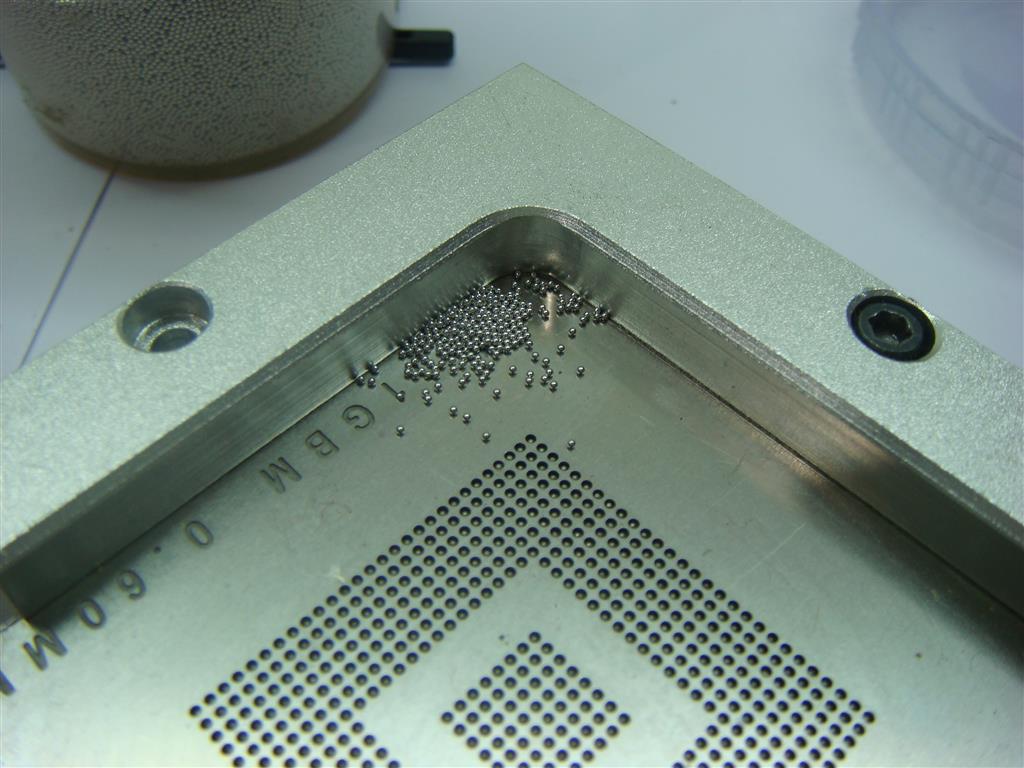

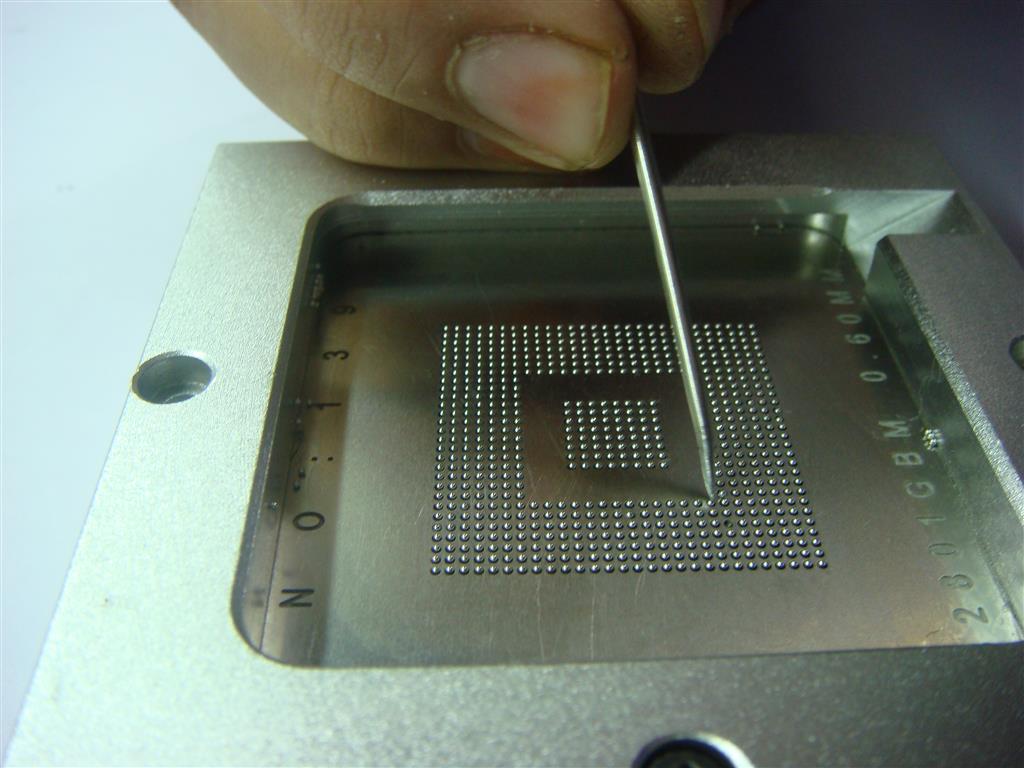

Grid aliened, chip ready for reballing.

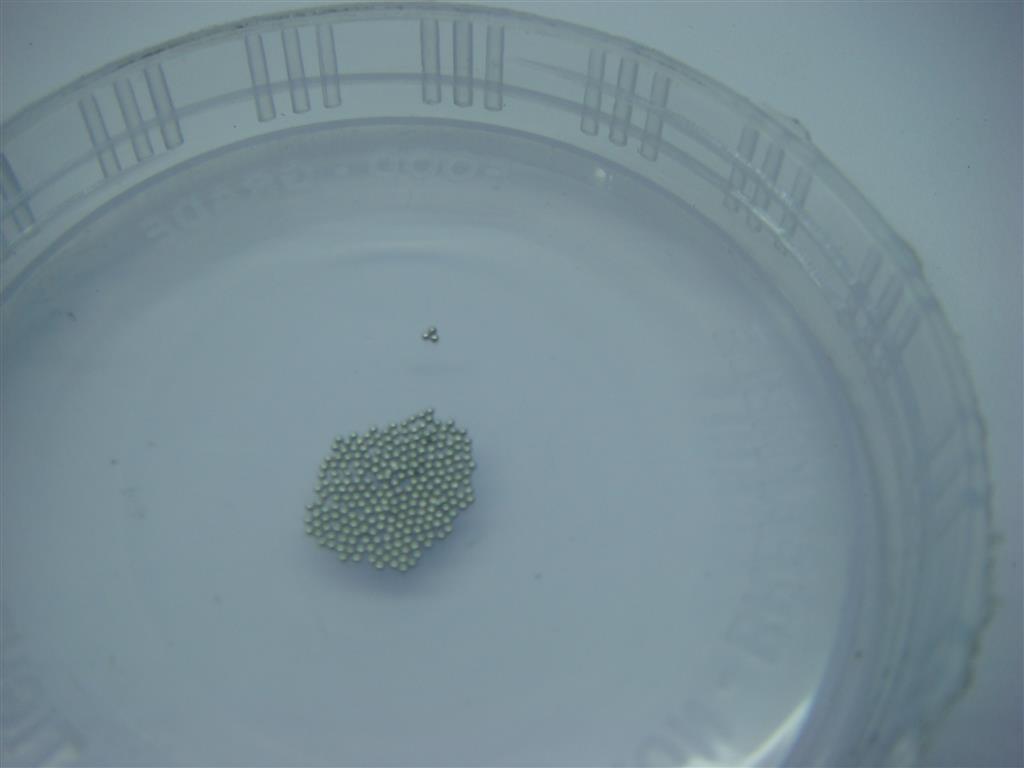

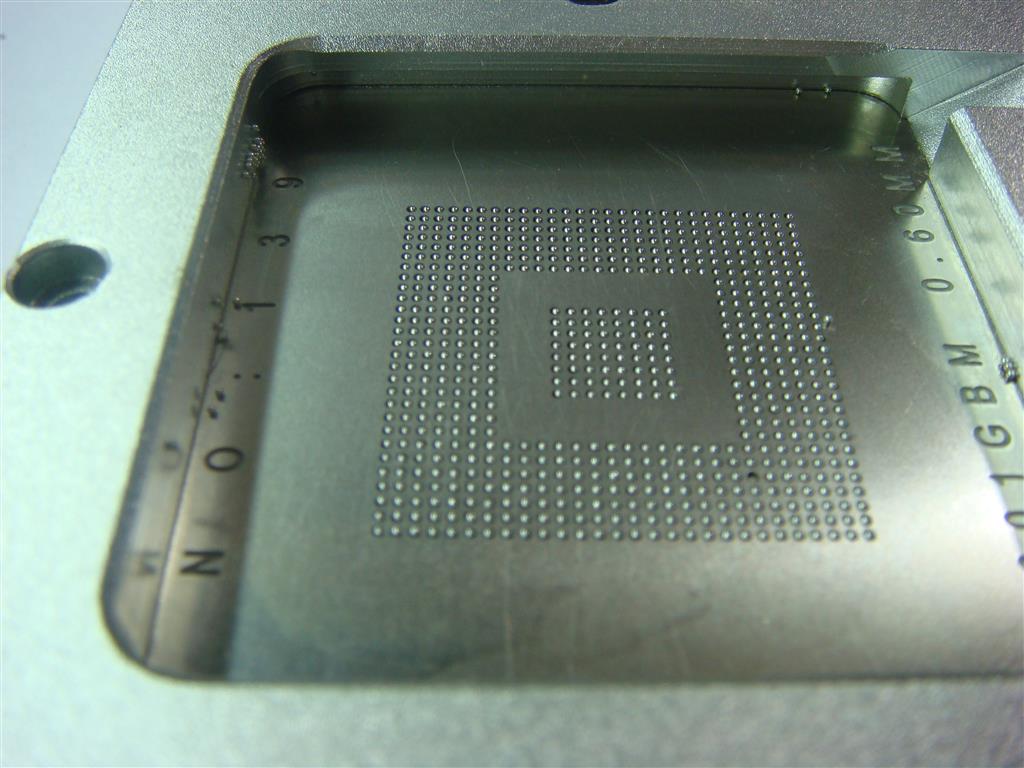

Ball properly falls into place.

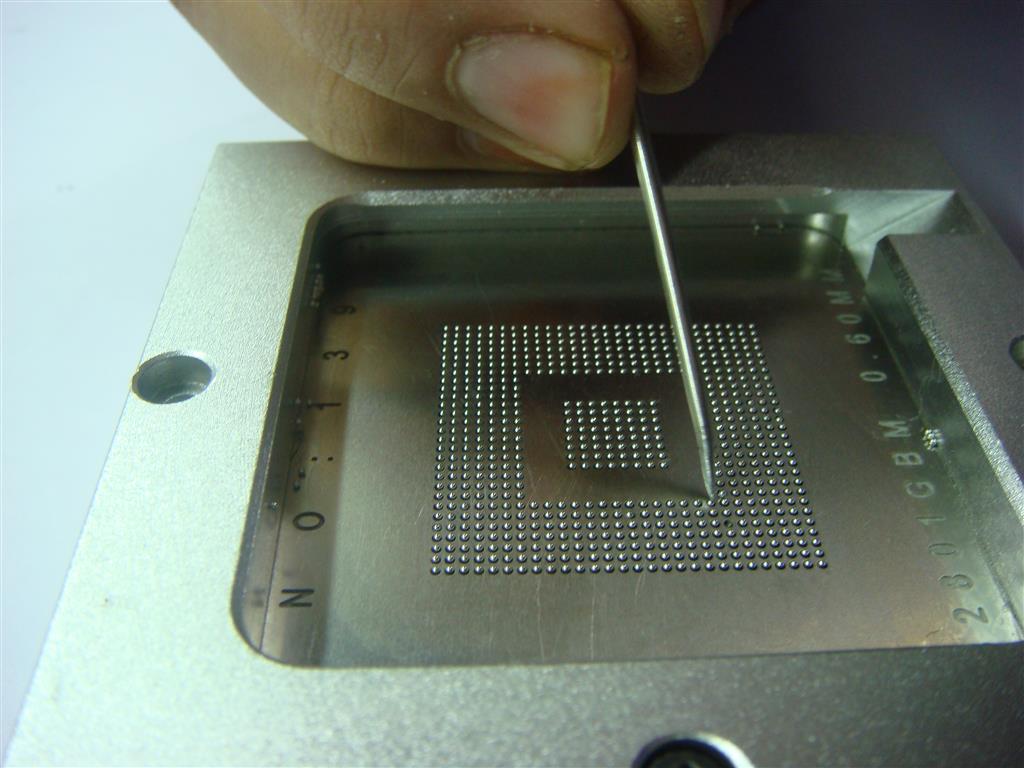

All missed holes are carefully populated with a ball using a fine needle.

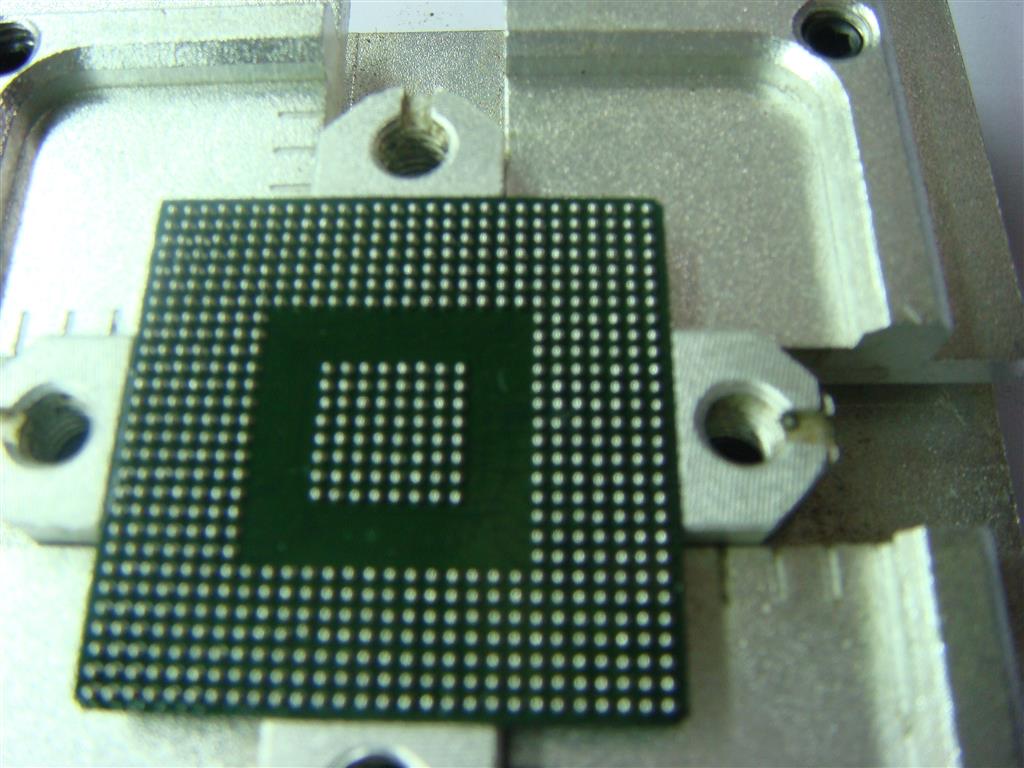

Perfect. New shiny ball are in place. Looks nice

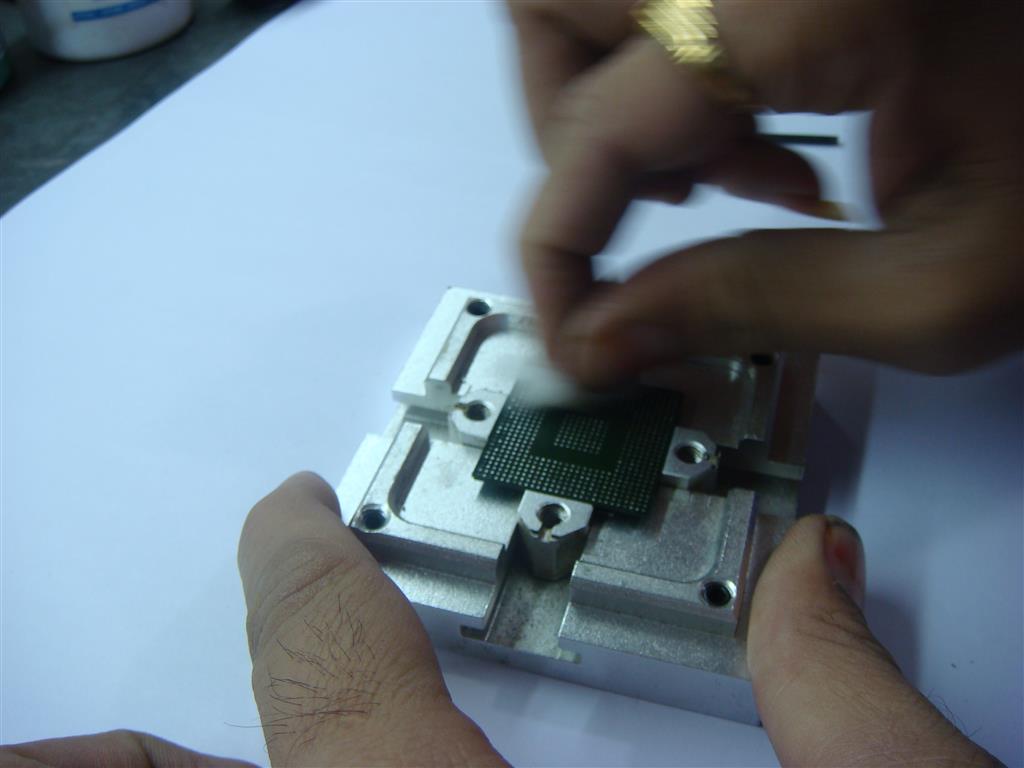

Little heat for removal of any excise flux applied during the ball placement stage.

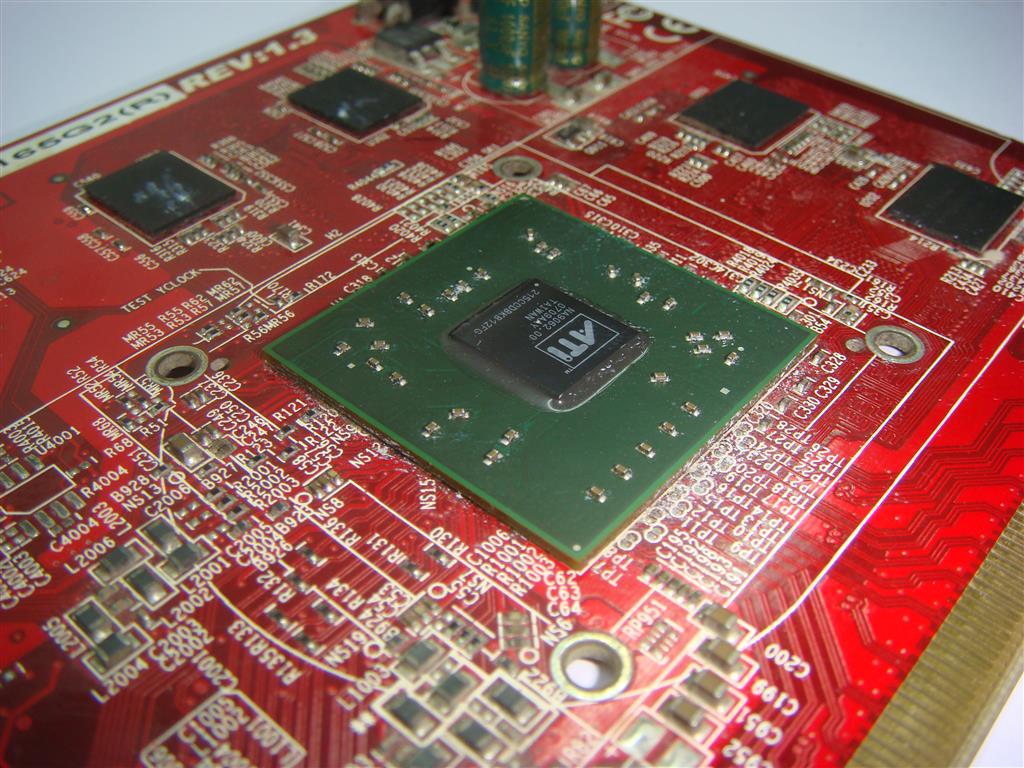

Now chip is carefully placed back on the circuit and controlled heat is applied for re-soldering.

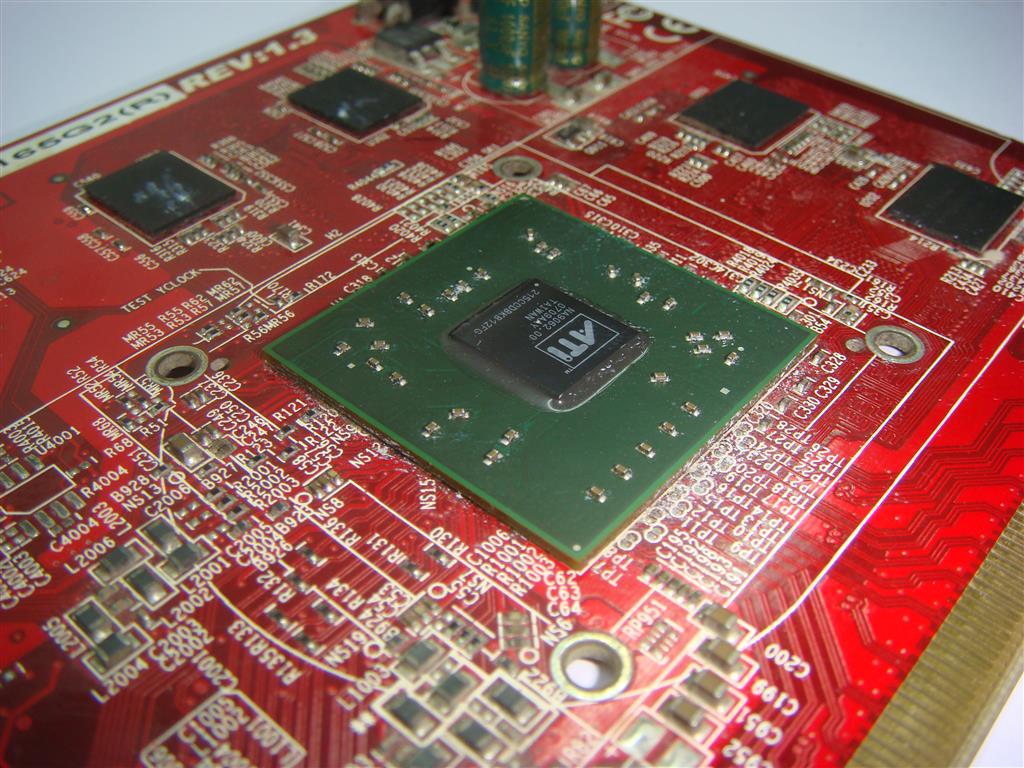

Perfect chip re-soldering

New thermal compound is applied and heat sink installed.

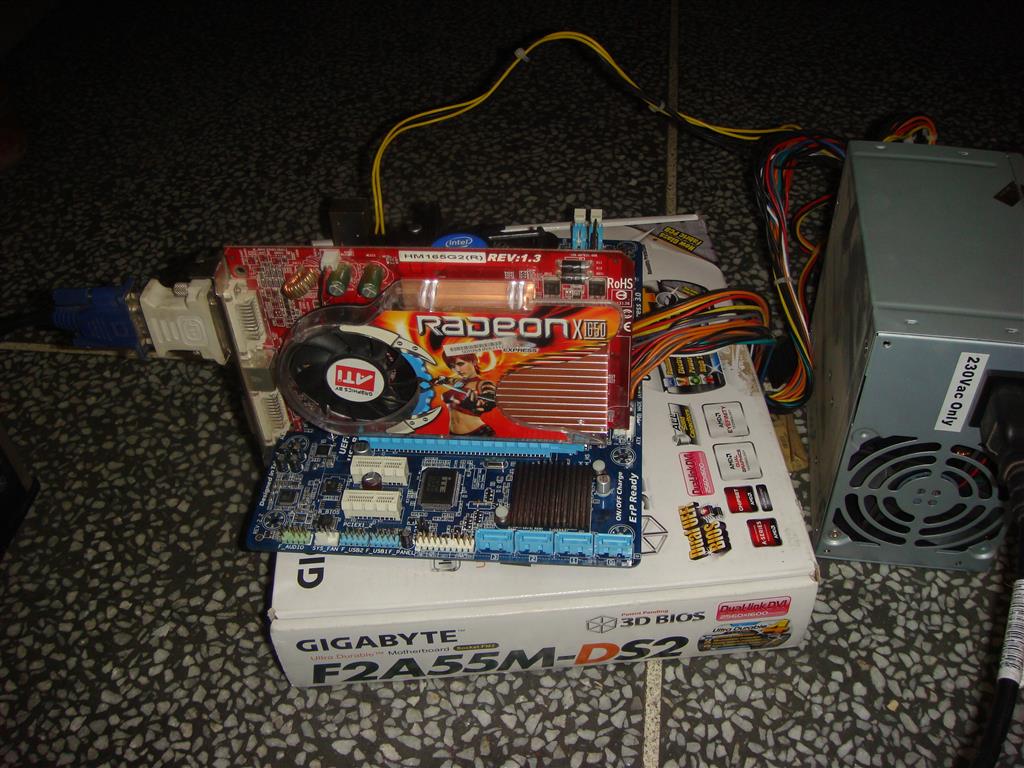

Test system ready. Now is the time that will show whether the GPU is back to life or gone forever.

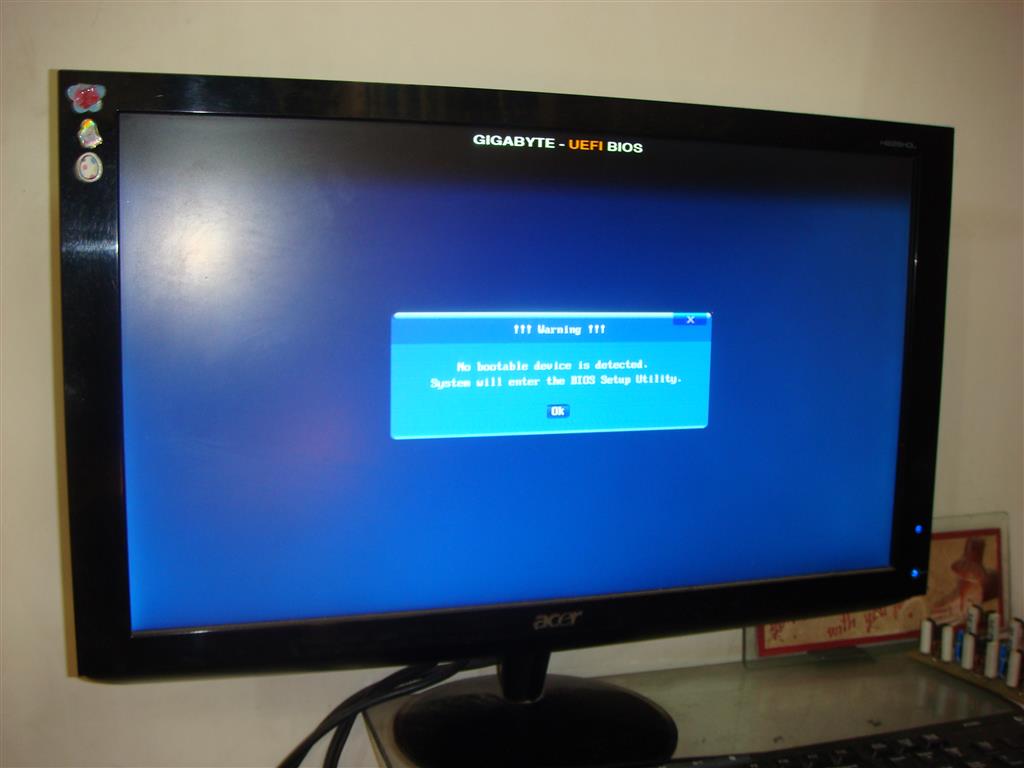

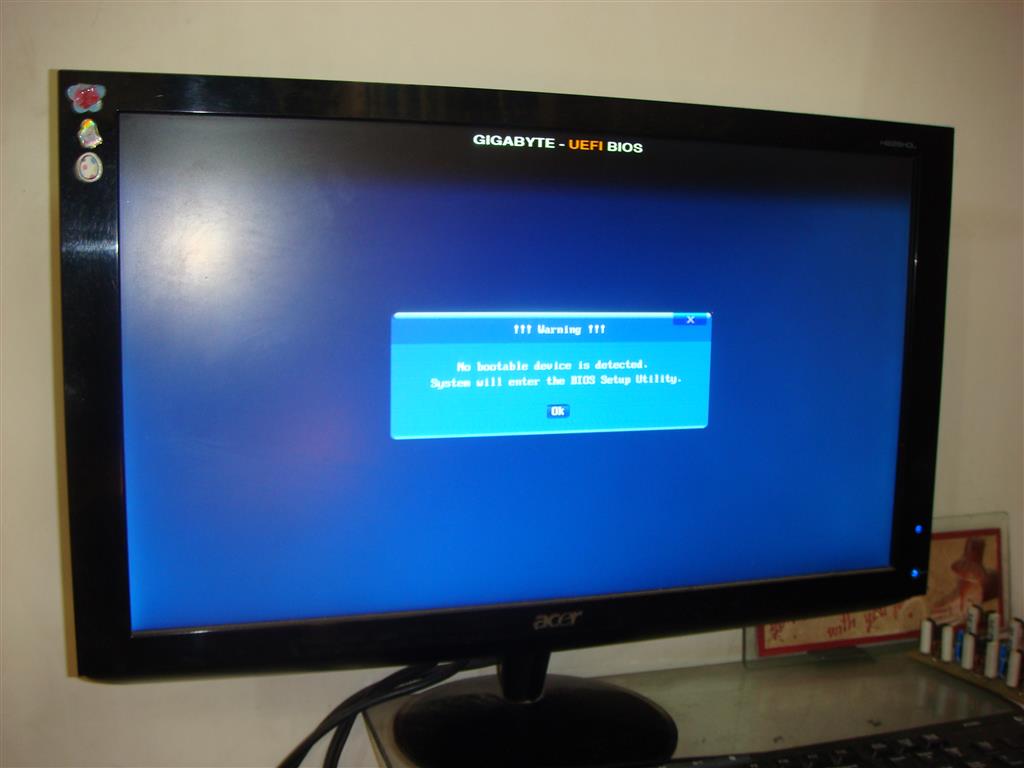

It’s live.. Success.

Some GTA san andreas run shows that GPU is 100% fine.

Hope you like this article.

Regards

Rakesh Sharma

Source / More Info

In this article I will show you how a dead graphics card is repaired. No oven baking, no do-it-yourself type trikes, just a pure professional repairs.

Meet the victim, my old no display, dead ATI-Radeon X1650 graphics card.

Removing the heat sink.

Thermal compound on the chip cleaned.

Now circuit board is installed on a BGA chip reflow machine.

Heater head mounted properly.

Machine in action

Within a minute chip is out.

There is very little space between chip and circuit board approx. 0.1mm still you can see their is dust under the chip. This dust, heat and moisture together sometimes oxides and breaks these fine connection resulting a GPU failure.

Chip is mounted on a reballing mount.

You can see many connection pins have gone black due to dust and oxide layer.

Heat cleaning the chip connection terminal.

Preparing the chip for new BGA soldering balls. Flux, 0.6mm lead free soldering BGA balls and grid.

Some close look on BGA soldering balls

Grid aliened, chip ready for reballing.

Ball properly falls into place.

All missed holes are carefully populated with a ball using a fine needle.

Perfect. New shiny ball are in place. Looks nice

Little heat for removal of any excise flux applied during the ball placement stage.

Now chip is carefully placed back on the circuit and controlled heat is applied for re-soldering.

Perfect chip re-soldering

New thermal compound is applied and heat sink installed.

Test system ready. Now is the time that will show whether the GPU is back to life or gone forever.

It’s live.. Success.

Some GTA san andreas run shows that GPU is 100% fine.

Hope you like this article.

Regards

Rakesh Sharma

Source / More Info

Last edited: