Something is not right if the month of import is future dated?!Upgraded from 1060 to RTX 3080 - Got it from amazon (appario retail) 103800/-( with 5% amazon pay cashback 98610/- ) which is the MRP. Strangely month of import printed is Dec 2020.

Sony 1000Mx4

Corsair Hx1000

The "Everyday" show-off thread !

- Thread starter Blade_Runner

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

alekhkhanna

Innovator

Damn time travel !Strangely month of import printed is Dec 2020.

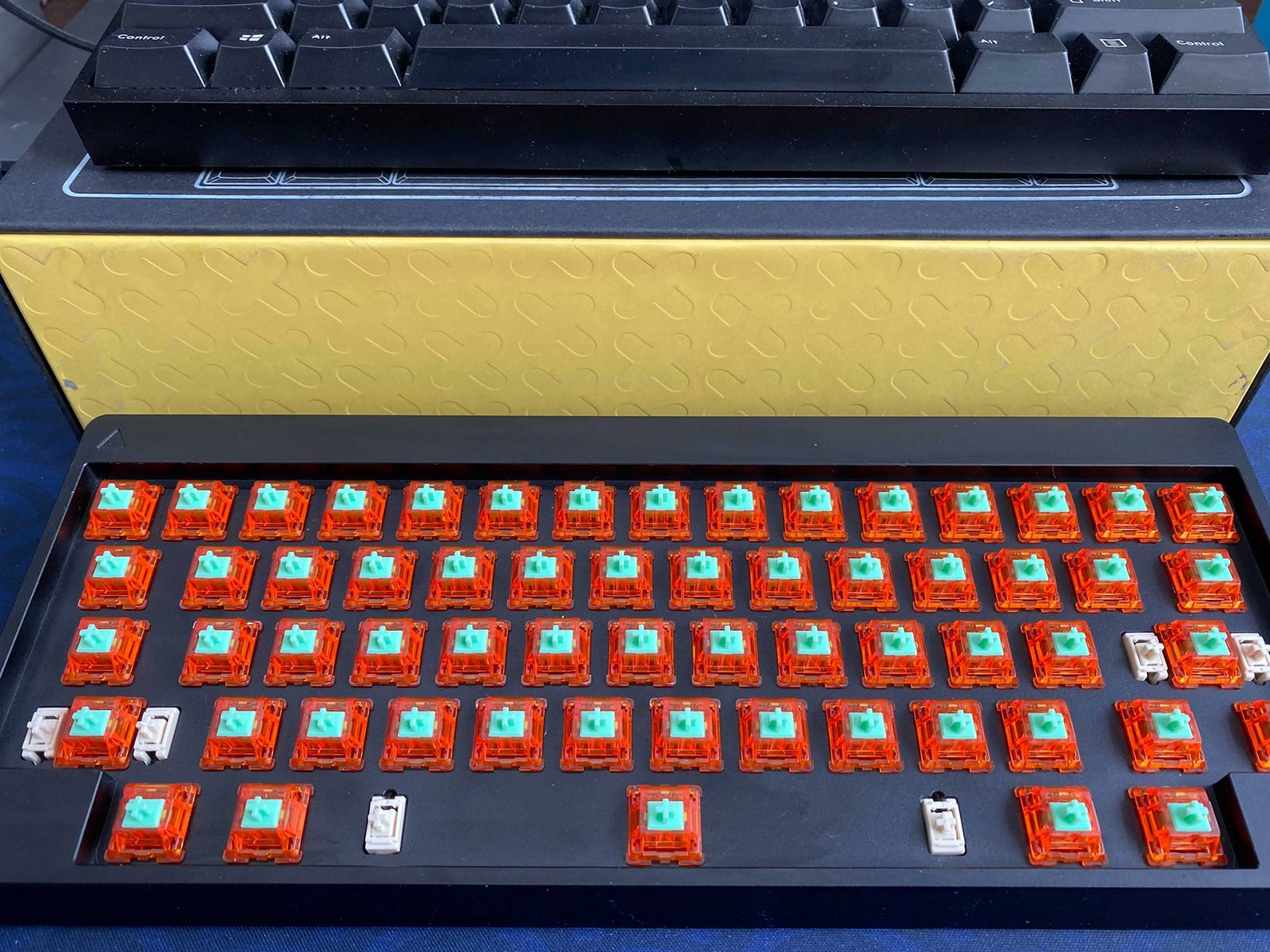

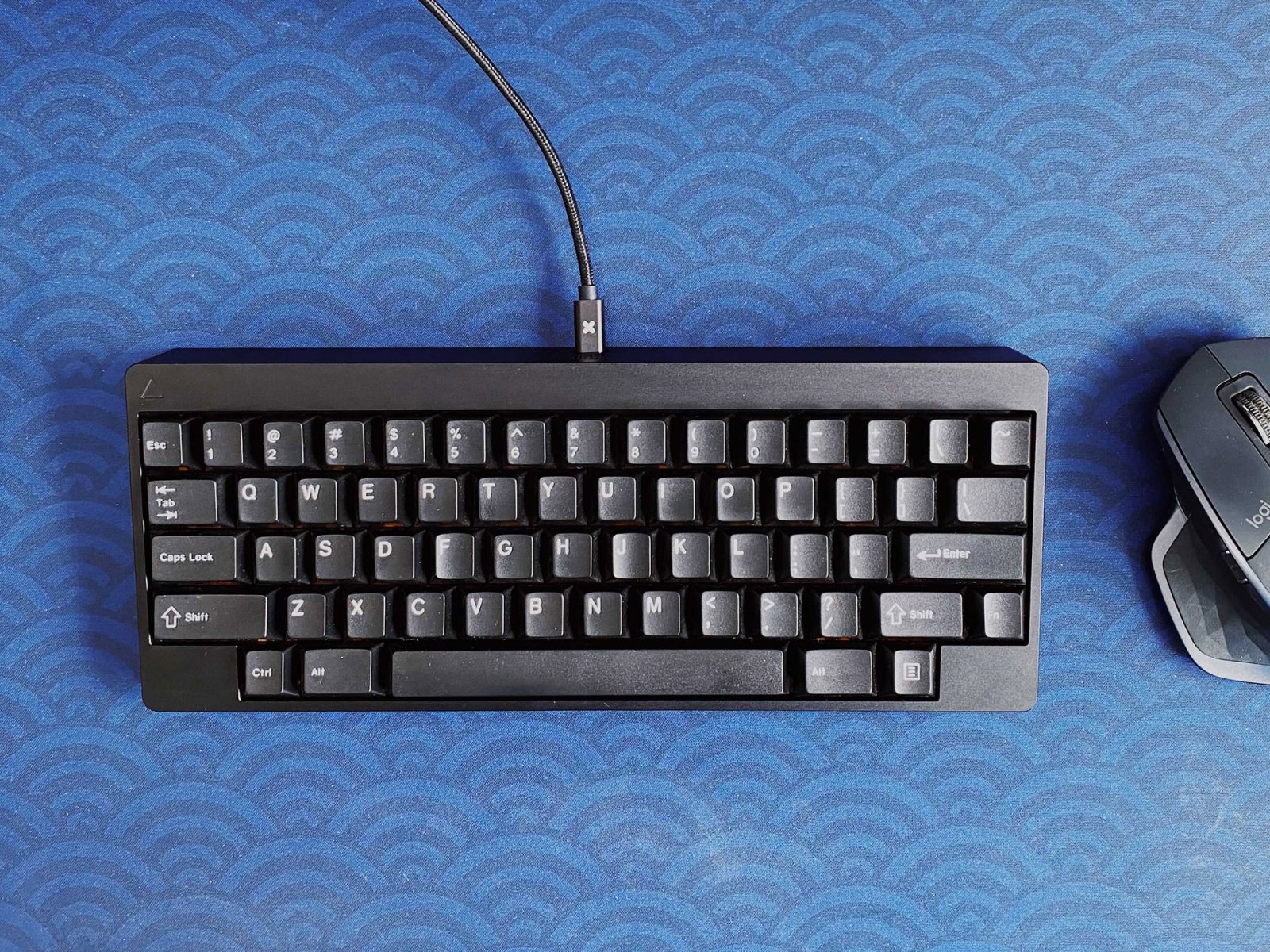

Finally built my Keyboard yesterday. Spent longer lubing the Stabilizers than the actual assembly.

total damages please? I am looking for a small(er) keyboard on a budget.Finally built my Keyboard yesterday. Spent longer lubing the Stabilizers than the actual assembly.

View attachment 94366View attachment 94365View attachment 94368View attachment 94367

Can't give you the approximate price of the keyboard (its quite a bit). But for reference, this is a RAMA M60-A Seq2, purchased aftermarket, as in it was part of a group buy, so the product ran only twice ever. On top of that this is a limited commission. If you check the mechanical keyboards aftermarket reddit (r/mechmarket) you'll find used M60-A's going for between 600-1000 USD.total damages please? I am looking for a small(er) keyboard on a budget.

The switches are easier to source, i got 70 of them for around 4.5k shipped. They're C3 Tangerine V2's and you can find them on most enthusiast websites in asia like ilumkb.com as well as switchkeys.com.au.

The keyboard stabilizers were also around 18usd (25usd shipped), they are C3 stabilizers, again purchased from ilumkb. The keycap set was around 60USD, it was the ePBT ABS WoB (White on Black) keycap set, which i picked up from a canadian vendor, but its available from ilumkb (based out of singapore) as well. Ill be changing the keycap set next week as i have the GMK WoB keycap set from Drop arriving shortly, which was 110usd (125usd shipped)

If you are looking for a smaller keyboard on a budget, there are a few choices, depending on your budget. You can head over to the Mechanical Keyboards India Subreddit or Discord Server (full disclosure, am a moderator there) to ask any questions you want answers to

kanishk619

Explorer

DIY power rack (minus fabrication) based on the space and my personal requirements.

Ekansh5

Apprentice

rdst_1

Juggernaut

View attachment 94561

View attachment 94562

DIY power rack (minus fabrication) based on the space and my personal requirements.

Looking great man. I have been thinking of building one for sometime now as well. I have been a little bit confused on whether to buy these square hollow pipes predrilled or drill them myself according to my needs.

letmein

Herald

kanishk619

Explorer

It took a lot of time to finalize with the design changes. The idea behind getting all holes drilled at once I can later on replace parts easily and won't have to touch the rack base (and aestheticsLooking great man. I have been thinking of building one for sometime now as well. I have been a little bit confused on whether to buy these square hollow pipes predrilled or drill them myself according to my needs.

). I added the pulley mechanism later on once I was confident. The pipes used are 3x3 10 gauge with 20mm holes spaced at every 2". I might change the functional weight slides with selectorized weight stack at some point but this is serving me well. If you plan to get it done yourself, find someone who can laser cut the holes instead of drilling.

). I added the pulley mechanism later on once I was confident. The pipes used are 3x3 10 gauge with 20mm holes spaced at every 2". I might change the functional weight slides with selectorized weight stack at some point but this is serving me well. If you plan to get it done yourself, find someone who can laser cut the holes instead of drilling.If you want to buy perforated pipes, you can have a look at https://www.universalsportsinds.com/functional-training-fitness/rigs/

But this is going to cost you a lot.

Last edited:

rdst_1

Juggernaut

Oh sorry. I missed the part where you had gotten it fabricated from elsewhere. I have a drill press and welding machine (if needed), so planning on tackling this myself.It took a lot of time to finalize with the design changes. The idea behind getting all holes drilled at once I can later on replace parts easily and won't have to touch the rack base (and aesthetics). I added the pulley mechanism later on once I was confident. The pipes used are 3x3 10 gauge with 20mm holes spaced at every 2". I might change the functional weight slides with selectorized weight stack at some point but this is serving me well. If you plan to get it done yourself, find someone who can laser cut the holes instead of drilling.

If you want to buy perforated pipes, you can have a look at https://www.universalsportsinds.com/functional-training-fitness/rigs/

But this is going to cost you a lot.

Did you get all the parts like the pull up bar, the spotter arms etc, apart from the frame, from the site you have mentioned above?

For now, just 2 sets of holes, one for spotting during bench press and one for squats should be enough for me as no one apart from me will be using the setup. Have seen people improvise and use 20mm GI pipes as spotter arms as well.

kanishk619

Explorer

I actually ended up getting spotter bars done from the leftover pipe. If you have a drill press at your place, it would make sense to do it yourself. Pull up bar was also fabricated, the USI attachments are for a smaller hole size (I think 15mm size). You will surely need a welding machine for welding support plates atleast.

stick/tig/mig? btw, you have welder then why are you even asking questions here start welding dude!Oh sorry. I missed the part where you had gotten it fabricated from elsewhere. I have a drill press and welding machine (if needed), so planning on tackling this myself.

Did you get all the parts like the pull up bar, the spotter arms etc, apart from the frame, from the site you have mentioned above?

For now, just 2 sets of holes, one for spotting during bench press and one for squats should be enough for me as no one apart from me will be using the setup. Have seen people improvise and use 20mm GI pipes as spotter arms as well.

rdst_1

Juggernaut

Hahaha... I will bro. I was just asking about the spotter arms or the barbell holder kinda things. If they are available for cheaper somewhere then I can just build the frame and incorporate them instead of making them as well by jugaad.stick/tig/mig? btw, you have welder then why are you even asking questions here start welding dude!

I gained 5lbs of lean muscle mass just by gawking at these images.View attachment 94561

View attachment 94562

DIY power rack (minus fabrication) based on the space and my personal requirements.

Total damages?

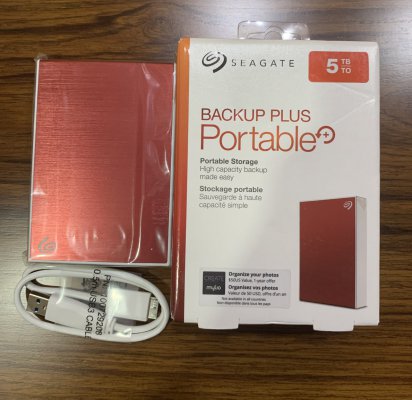

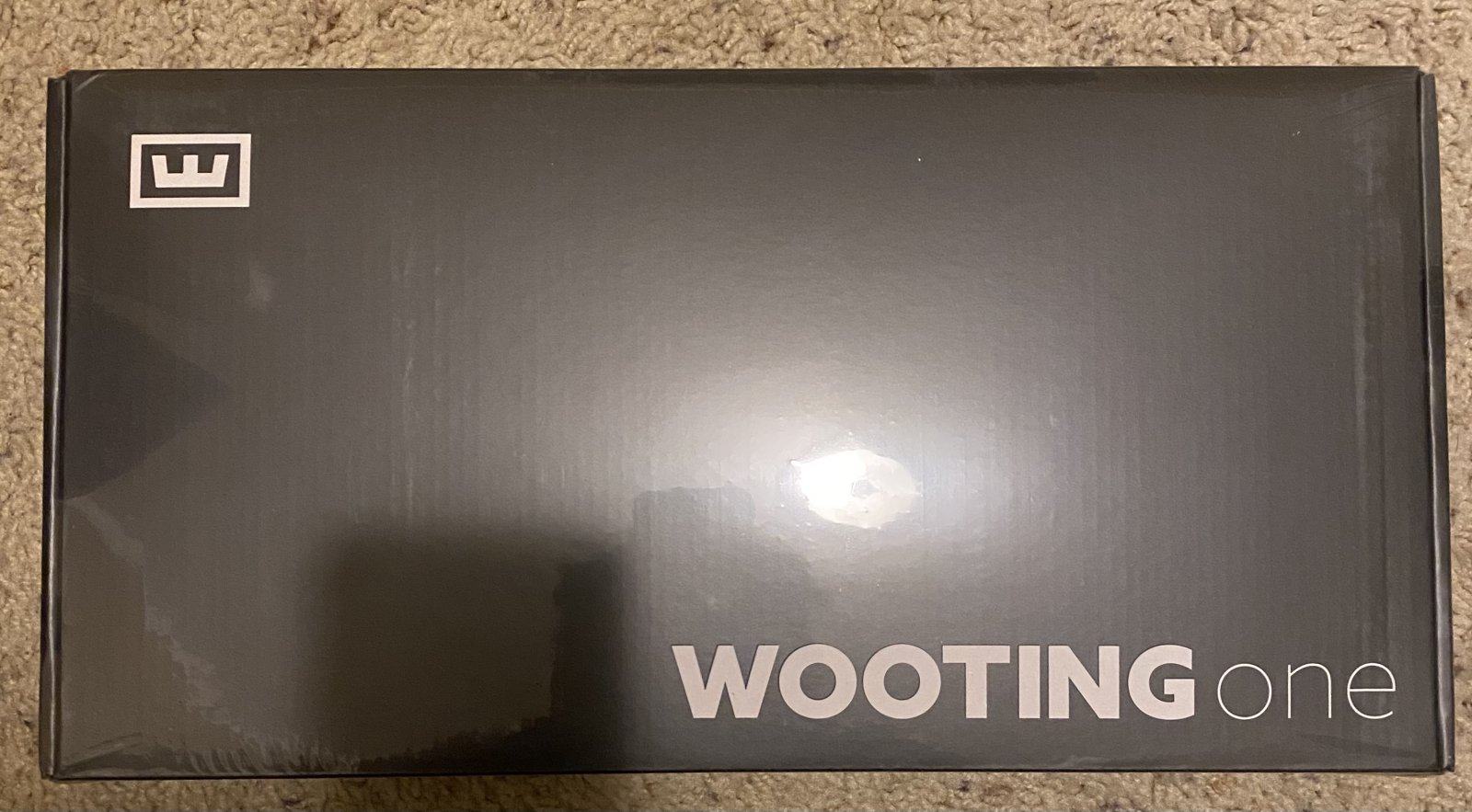

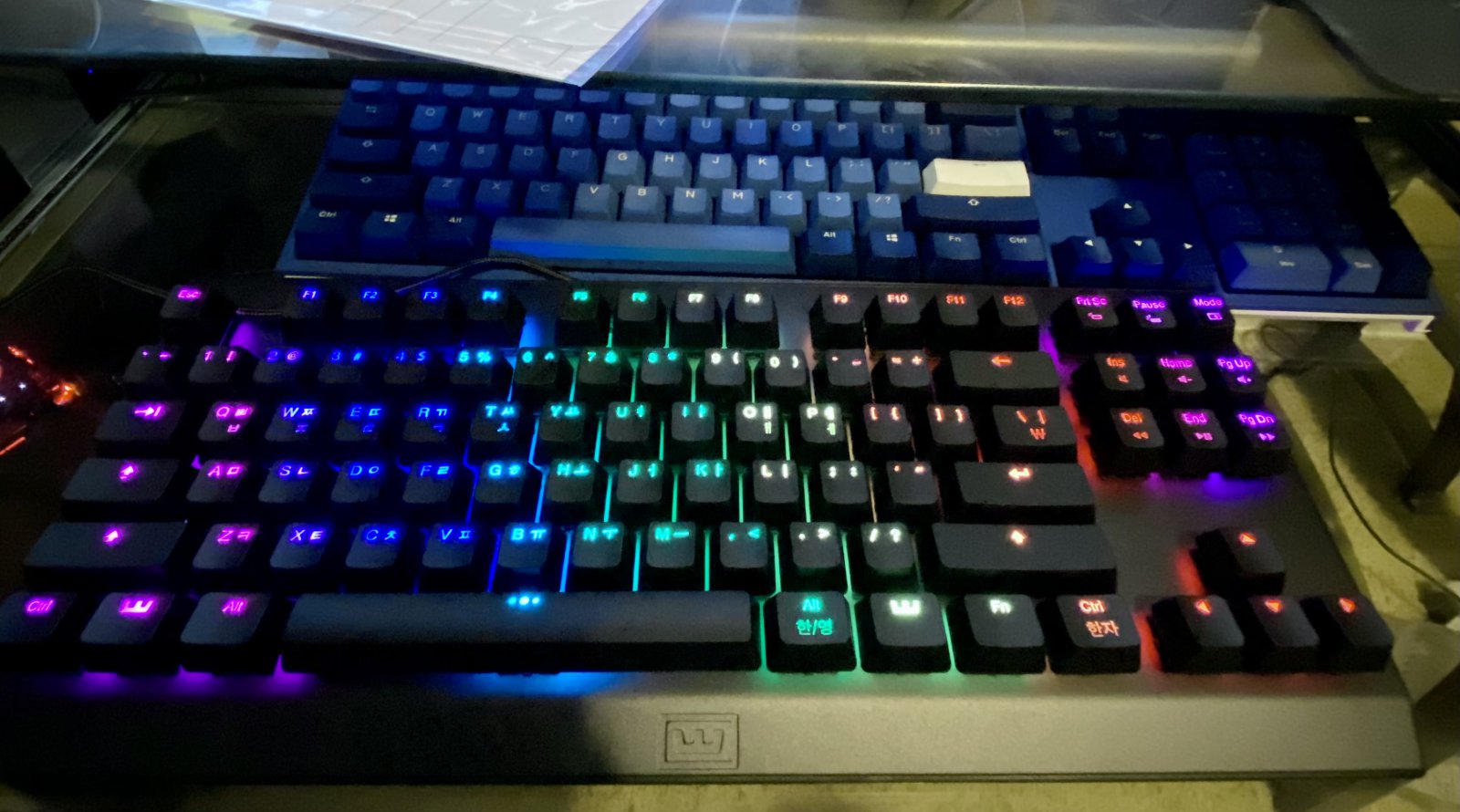

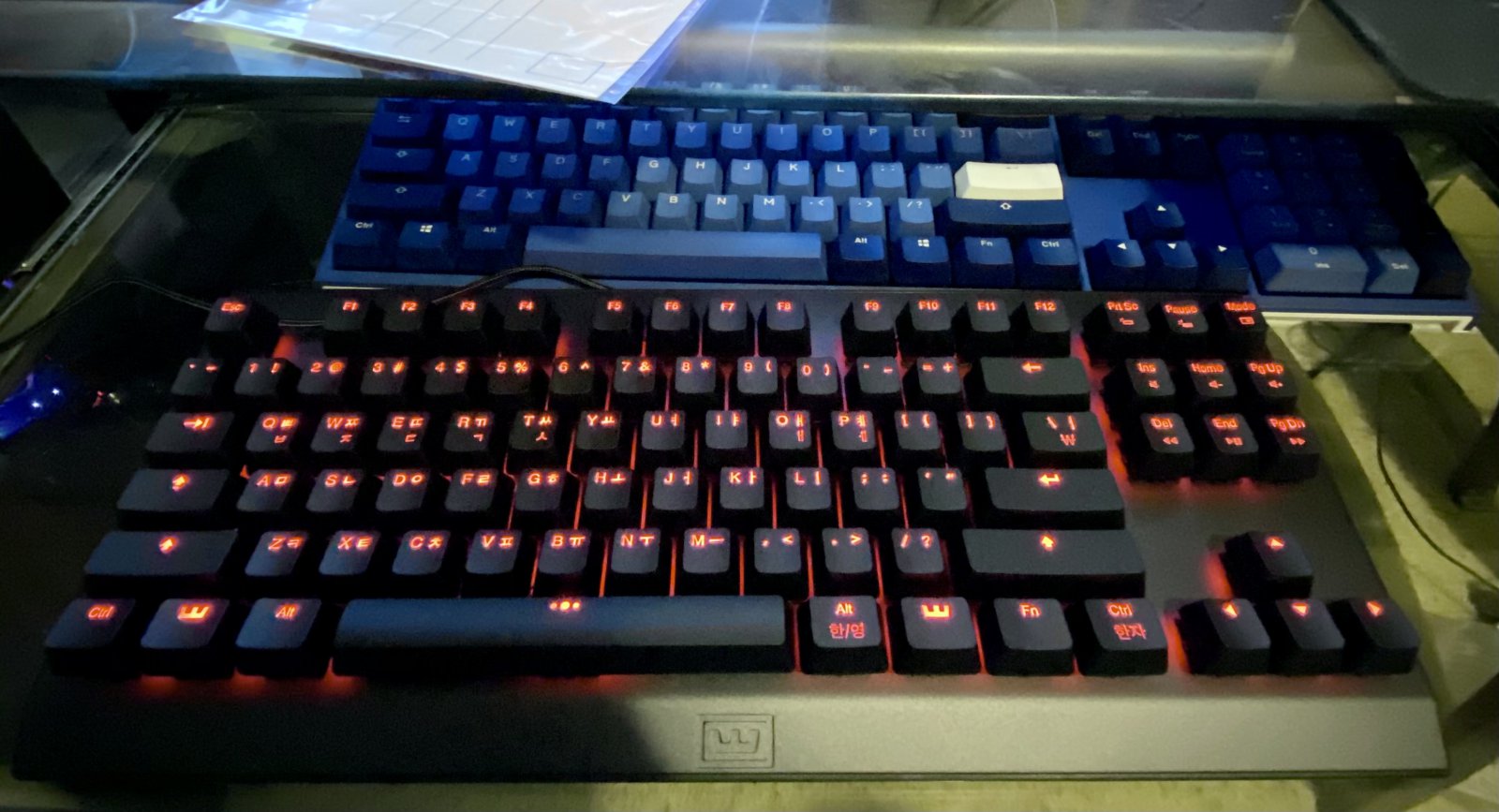

pretty thing arrived today. looks and feels great. wanted a better keyboard at work. currently use a gaetron 61 keyboard and wanted something better with arrow keys. gaetron required fn keypress for arrow keys and bit of a hassle when using with terminal and vi. this one is supposed to feel like blue keys and pleasantly surprised to see software for linux. changing color presets using software is fun.

damage ?pretty thing arrived today. looks and feels great. wanted a better keyboard at work. currently use a gaetron 61 keyboard and wanted something better with arrow keys. gaetron required fn keypress for arrow keys and bit of a hassle when using with terminal and vi. this one is supposed to feel like blue keys and pleasantly surprised to see software for linux. changing color presets using software is fun.View attachment 94665

View attachment 94666

View attachment 94667

View attachment 94668

kanishk619

Explorer

Almost 70k on the rack.I gained 5lbs of lean muscle mass just by gawking at these images.

Total damages?

Pipe cost: 15k

nuts and bolts: 3k

linear bearings: 3k

steel rods: 10k

holes: ~11k

pulleys: 6k

handles: 7k

powder coating: 4k

rest: on other raw material and labour

Since this was done on my own with no prior experience about material and gym machines, I can confidently say that I've spent some extra amount here and there but that's the perk of diy, you learn something new everyday.

I bought the bench from market for 10k and the 150kg plates for around 22k. Barbell was around 4k and stall mats around 6k. I also spent around 20k on Bullrock adjustable dumbbells but send it back and got refund. So overall cost of the setup comes to ~1.15L.